Novel online power test control circuit

A technology for power supply testing and control circuits, applied in power supply testing, components of electrical measuring instruments, measuring electricity, etc., can solve the problems of cumbersome, easily damaged power supply, unable to meet the requirements of large-scale and rapid, and achieve reliable fixation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

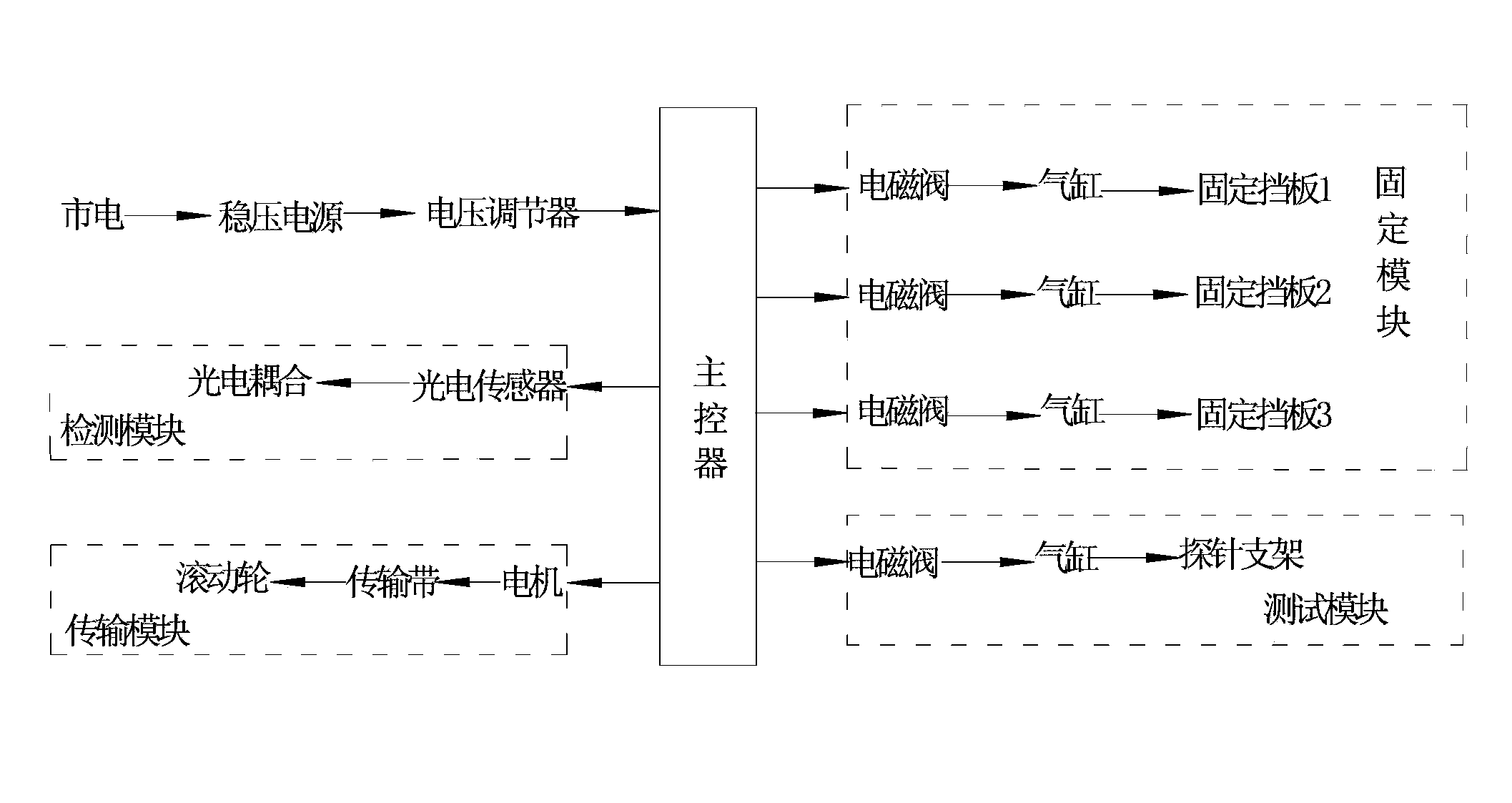

[0012] Referring to the accompanying drawings, the technical solution adopted by the present invention is: a novel online power supply test control circuit, including a main controller, a detection module connected to the main controller, a transmission module, a fixed module and a test module, the detection module A photoelectric sensor is used to detect the position of the tested power supply; the transmission module is driven by a motor to control the rolling wheel to drive the transmission belt to work; the test module is connected to the probe bracket by the cylinder to provide power for the crimping process of the probe bracket; The positioning device is fixed from three directions by the first fixed baffle 1 , the second fixed baffle 2 and the third fixed baffle 3 .

[0013] Further, the photoelectric sensor of the detection module adopts photoelectric coupling.

[0014] Further, the three fixed baffles of the fixed module are respectively controlled by three air cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com