Automatic packing machine for corrugated boxes

An automatic packaging machine and corrugated box technology, applied in the field of cartons, can solve the problems of destroying the structure of cartons, inconvenient reuse of cartons, and increasing the labor intensity of staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

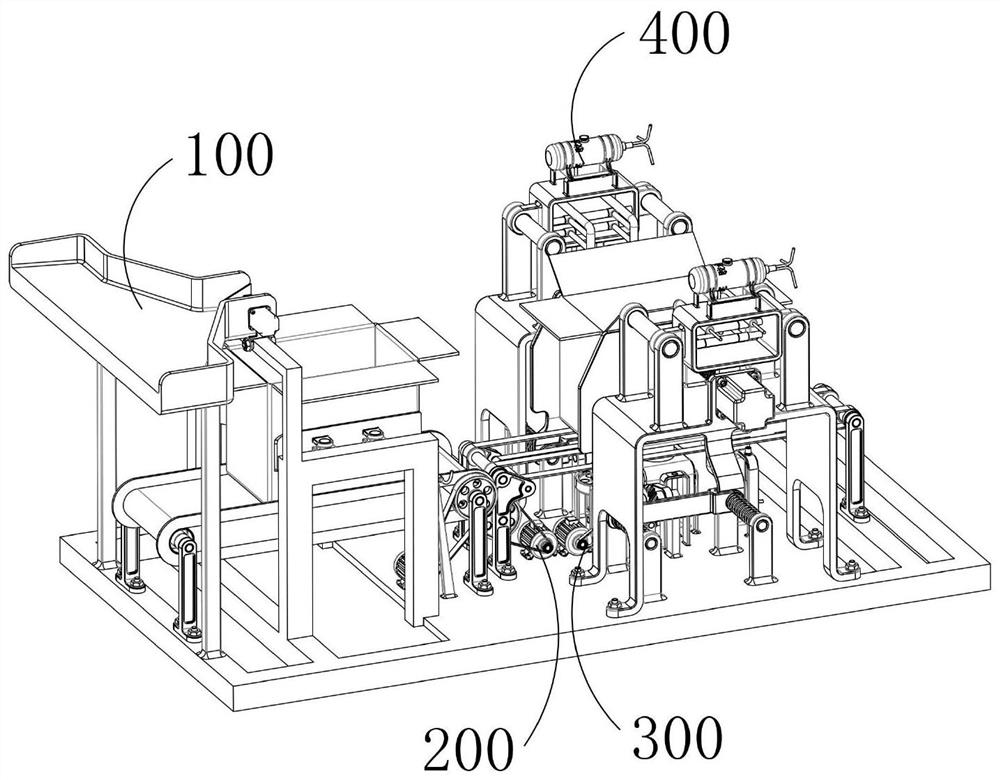

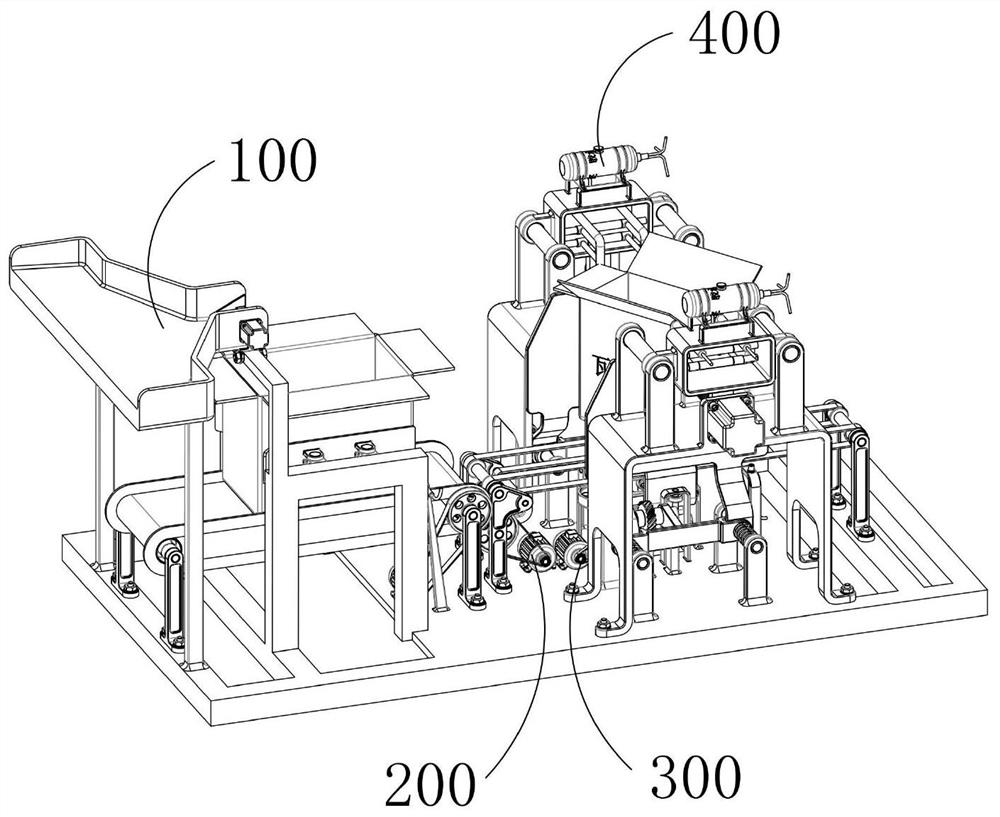

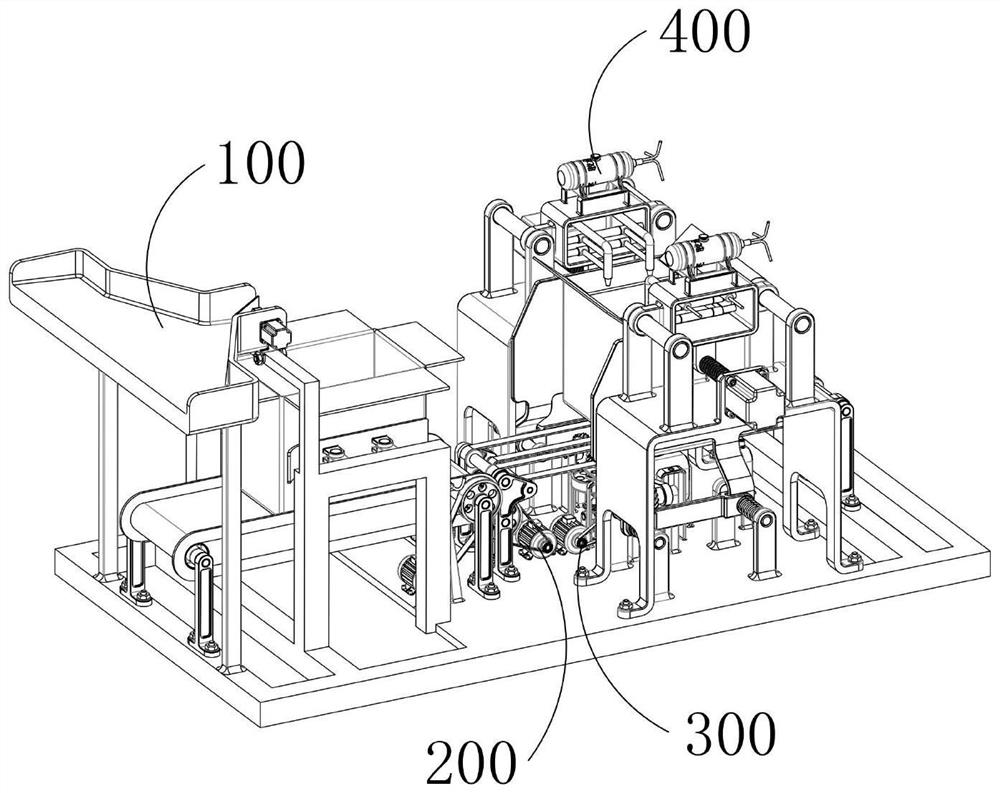

[0072] The present invention adopts the combination of the rotating mechanism and the packing mechanism to seal the cartons. It is folded in a horizontal device, and the whole process is realized through the controller to control the operation of the motor, which does not require workers to do high-intensity sealing work, which greatly reduces the labor intensity of workers; during the transportation of cartons, it is realized through the cooperation of positioning plate 1 and positioning components. Positioning and clamping to ensure that the carton will not have a position deviation and avoid adverse effects on the subsequent sealing and packaging process. In addition, the packaging mechanism uses glue to seal the carton, which can effectively reduce the damage of the carton during the disassembly process , to realize the recycling of cartons.

[0073] An automatic packaging machine for corrugated boxes, including a base installed on the ground, a loading device for filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com