Electric heating element, softening device and control method thereof

A technology for electric heating elements and electric heating devices, which is applied in the direction of heating elements, electric heating devices, ohmic resistance heating parts, etc., and can solve the problems of repeated bending of metal electric heating wires, broken insulation of metal electric heating wires, and hard insulation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

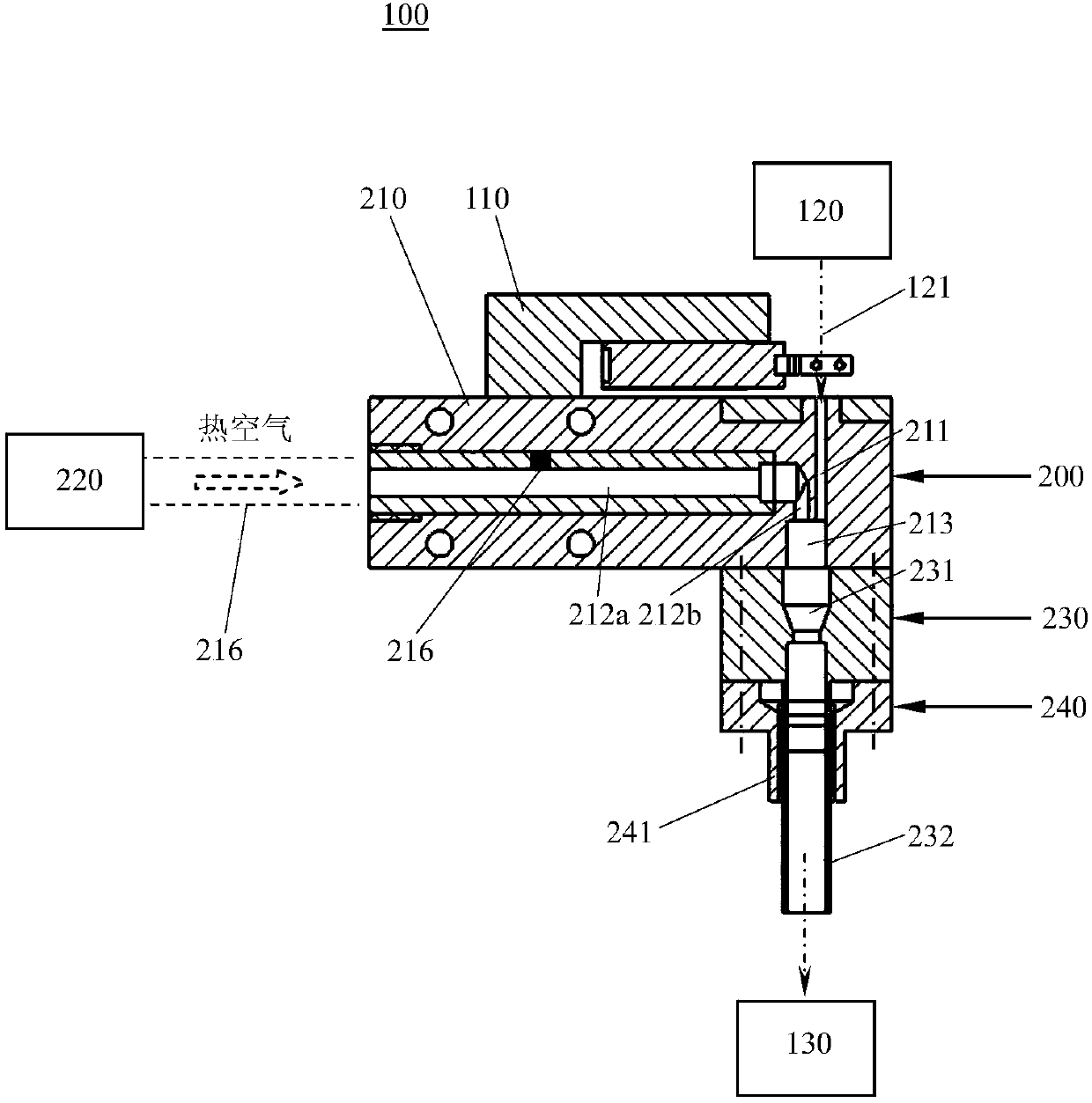

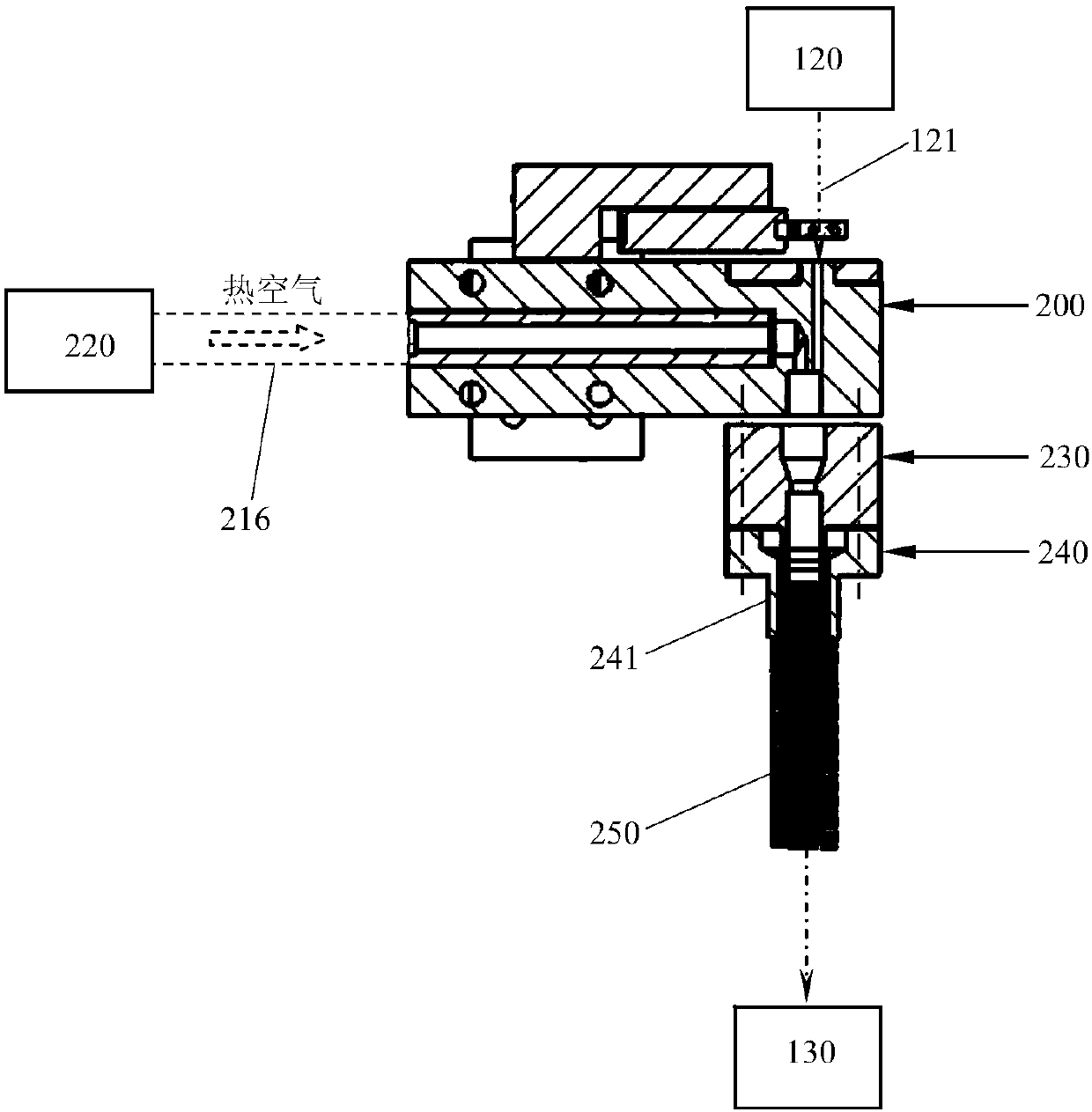

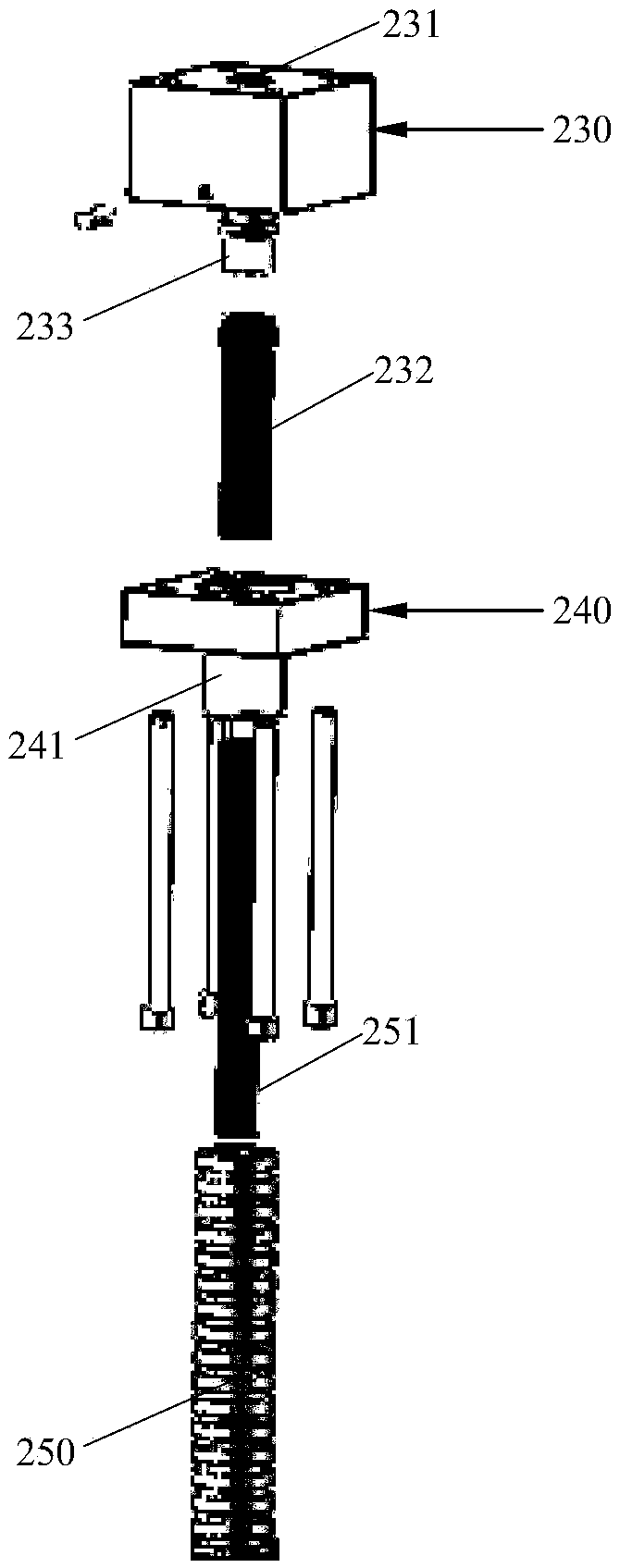

[0038] figure 1 A simplified schematic diagram of a sewing device 100 for sewing electric heating elements, in particular metallic electric heating wires, to a cushion, for example a car interior seat cushion or back cushion, is schematically shown. The sewing device 100 generally includes a fixed frame 110 , a feeding device 120 mounted on the frame 110 , and a sewing head 130 that can move relative to the frame 110 as required.

[0039] In this application, the electric heating element is an elongated electric heating body covered with an insulating skin, which can be sewn onto the base material of the pad through the sewing head 130, so as to realize the heating function after being energized. As mentioned in the background technology section of the description, for the metal electric heating wire covered with insulation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com