Pre-stressed prefabricated fabricated structure and penetrating and delivering steel strand composite device

A technology of prefabricated assembly and combination device, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve problems such as anchoring failure and the structure cannot be completed at one time, achieve stable stress, and solve the problem of penetrating steel strands. Good speed and force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

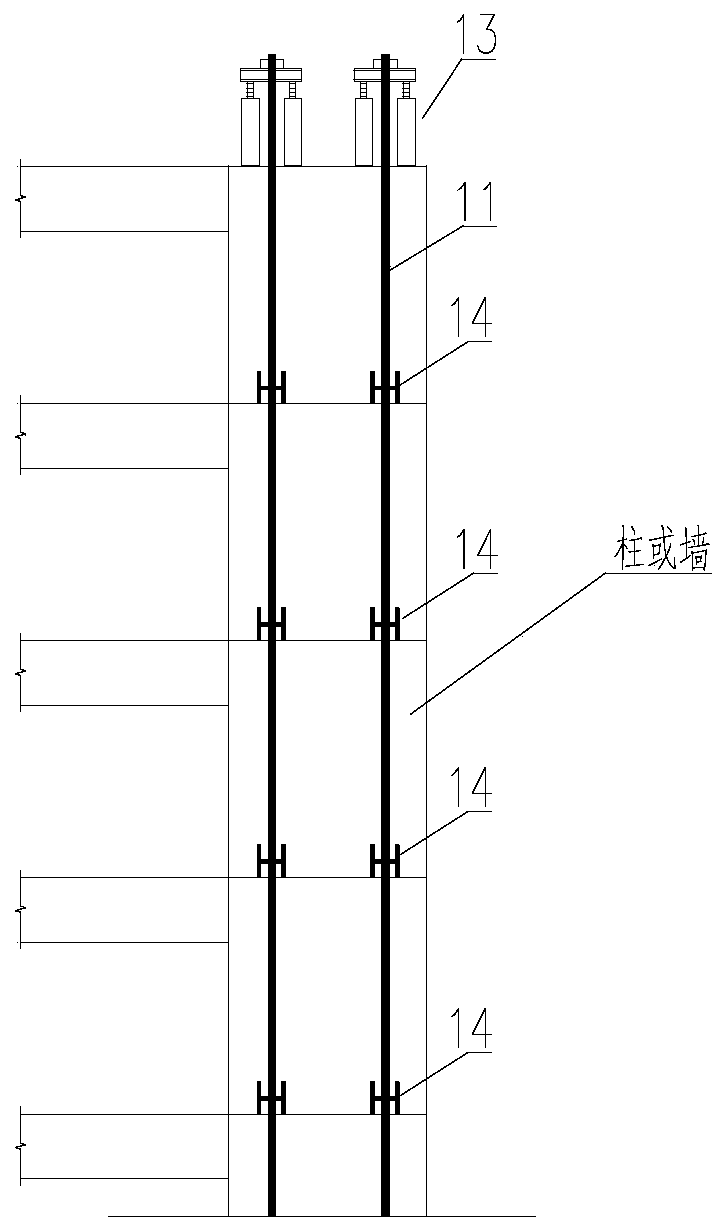

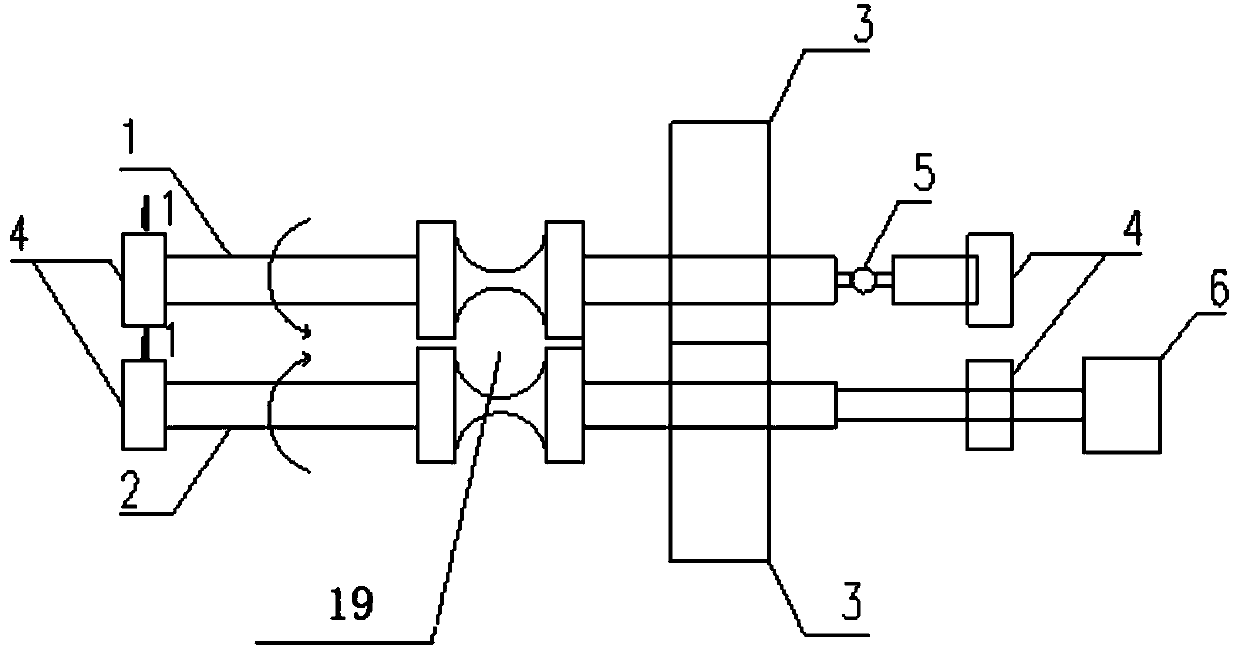

[0024] like Figure 1-10 As shown, a prestressed prefabricated assembly structure and a steel strand threading combination device include a steel strand 11, a threading machine 12, a conveying shaft 7, a temporary self-locking device 13 and a floor fixing device 14;

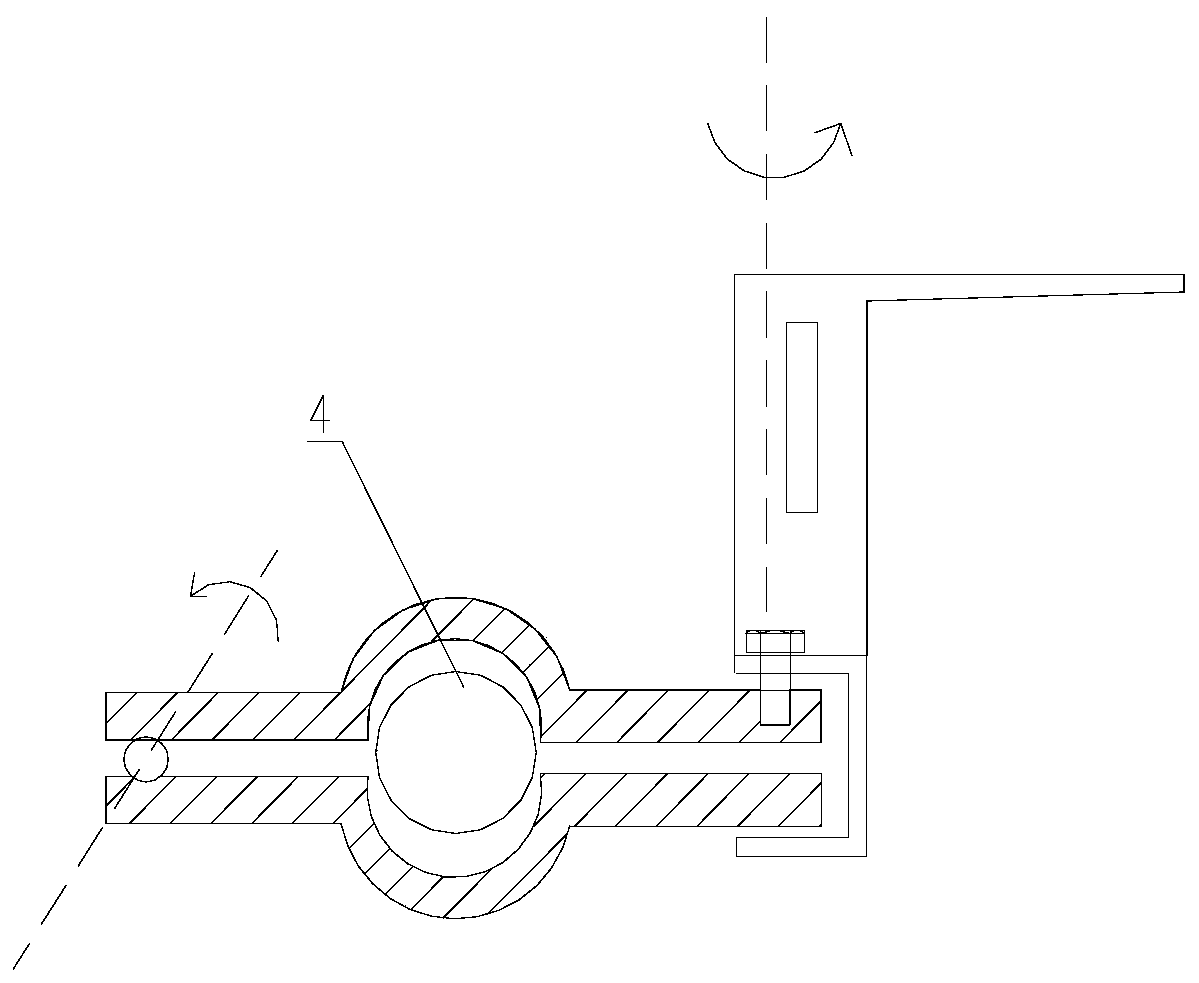

[0025] The threading machine 12 includes a threading driving shaft 1, a threading driven shaft 2, a gear 3, a steering knuckle 5, a bearing 4 and a power unit 6, the threading driving shaft 2 is connected with the power unit 6, and the threading driven shaft 2 is driven to rotate by the gear 3; The steering knuckle 5 is installed on the threading passive shaft 2, and the threading passive shaft 2 can be rotated and opened and closed around the steering knuckle 5. When opening, the steel strand 11 is put in or the threading machine 12 is removed, and the steel strand 11 is put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com