A method for determining the level of rockbursts occurring in tunnel tbm cutterheads

A determination method and rockburst technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problem of difficulty in accurately determining the rockburst grade in the TBM cutter head, achieve the scientific and accurate rockburst grade determination, and avoid grade determination deviation. , determine the timely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment the present invention is described in further detail:

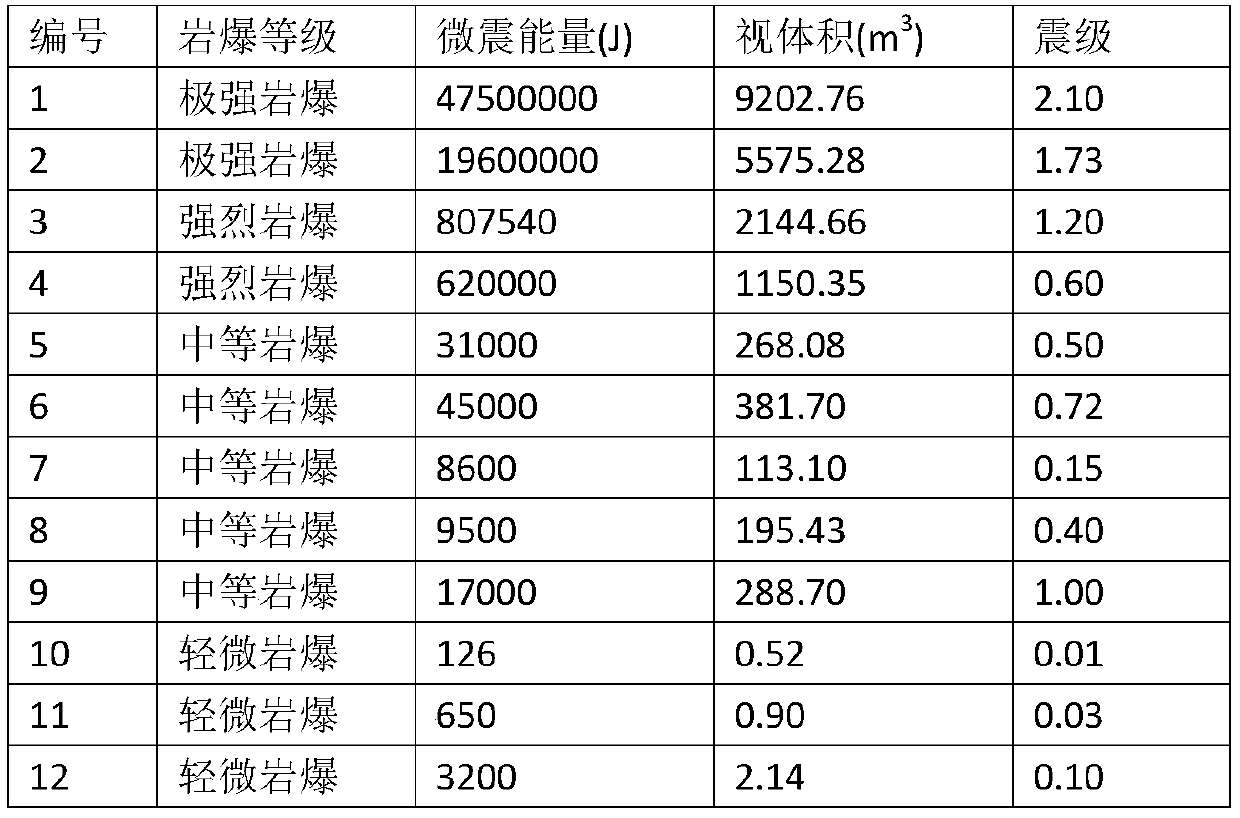

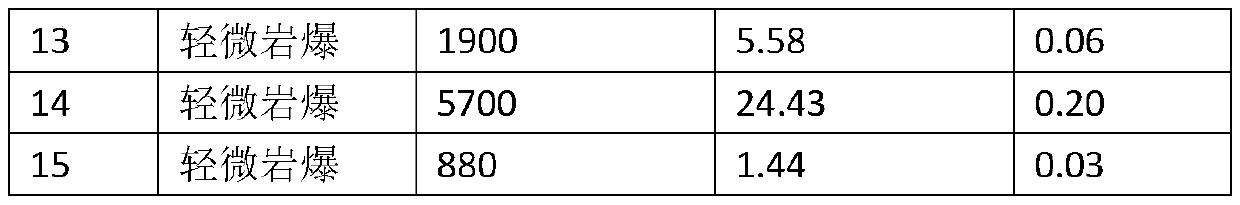

[0020] Microseismic sensors were installed in a deep TBM tunnel, and microseismic monitoring was carried out for one month. A total of 24 rockbursts of different intensities occurred outside and inside the TBM cutterhead were monitored, of which 15 rockbursts occurred outside the TBM cutterhead;

[0021] Determine the rockburst level by measuring the size of the above-mentioned 15 rockburst craters, the observed ejection of rock blocks, and the size of the sound; after judging, the extremely strong rockburst, strong rockburst, moderate rockburst and slight rockburst are respectively 2 1, 2, 5 and 6;

[0022] The microseismic energy, apparent volume, and magnitude three types of microseismic parameter values released by the above 15 rockbursts of different grades were determined through microseismic monitoring, and are shown in Table 1 after sorting out.

[0023] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com