Drillable packer and setting tool

A packer and tool technology, applied in the direction of sealing/isolation, drill pipe, drill pipe, etc., can solve problems such as blockage, cement slurry hole closing failure, and easy fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

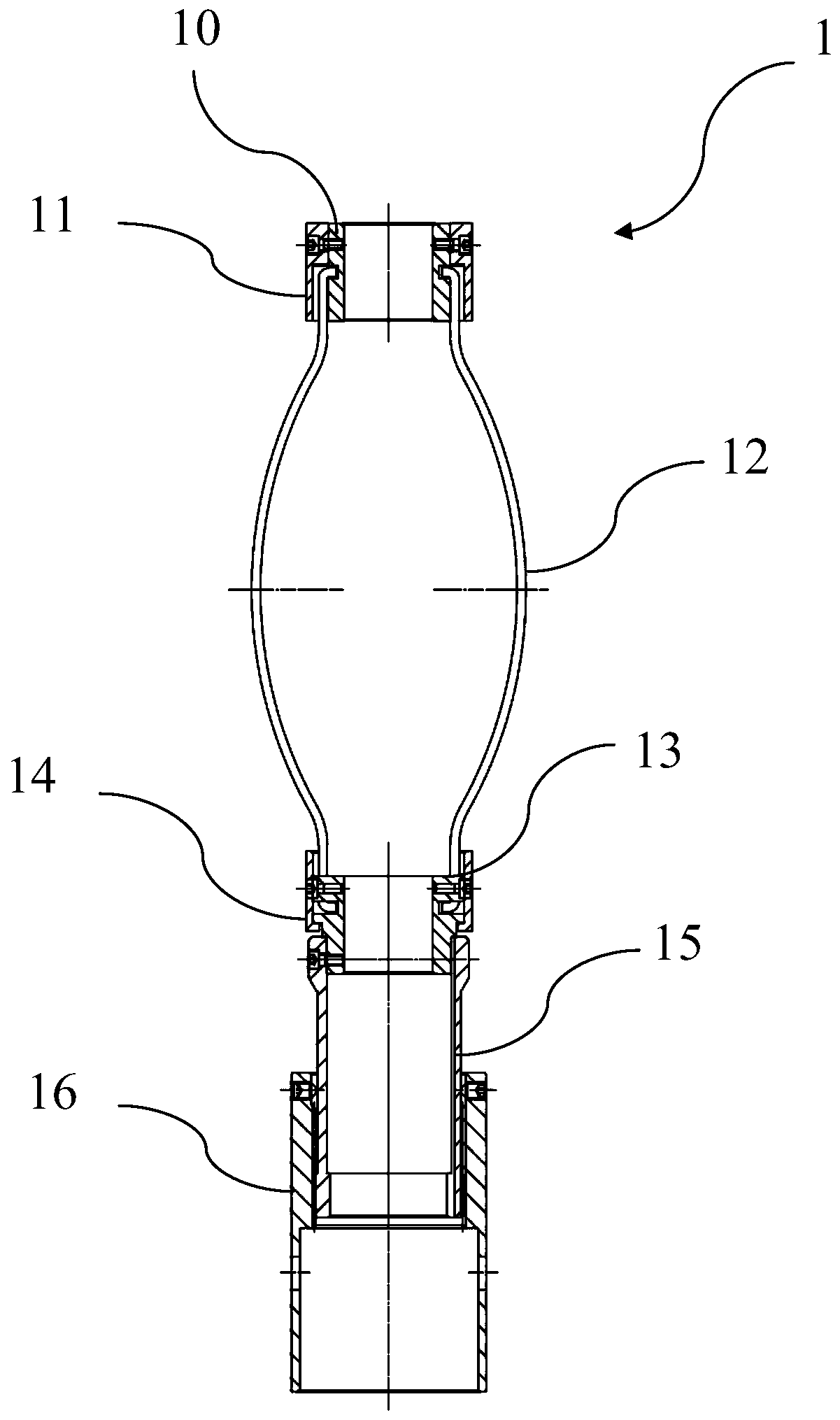

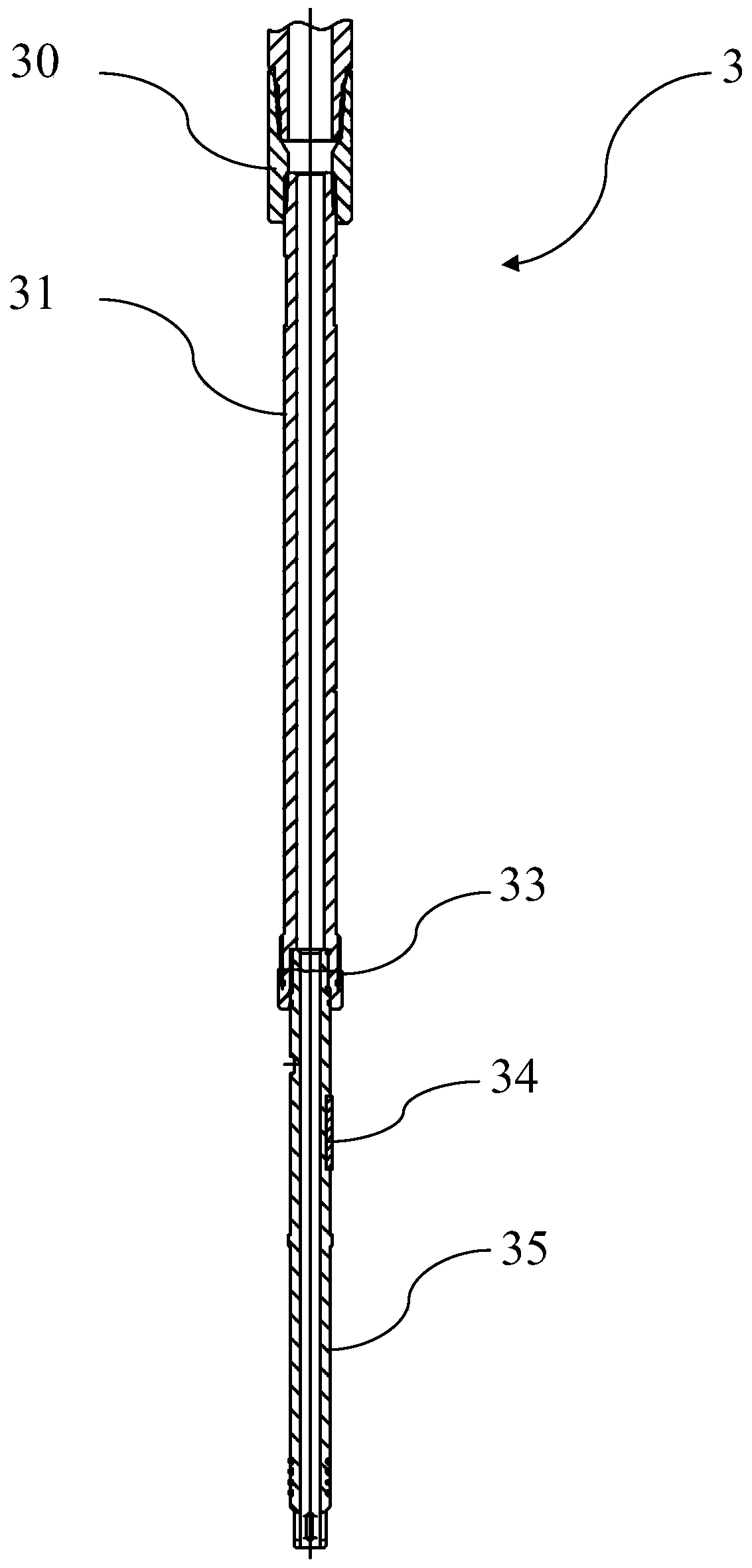

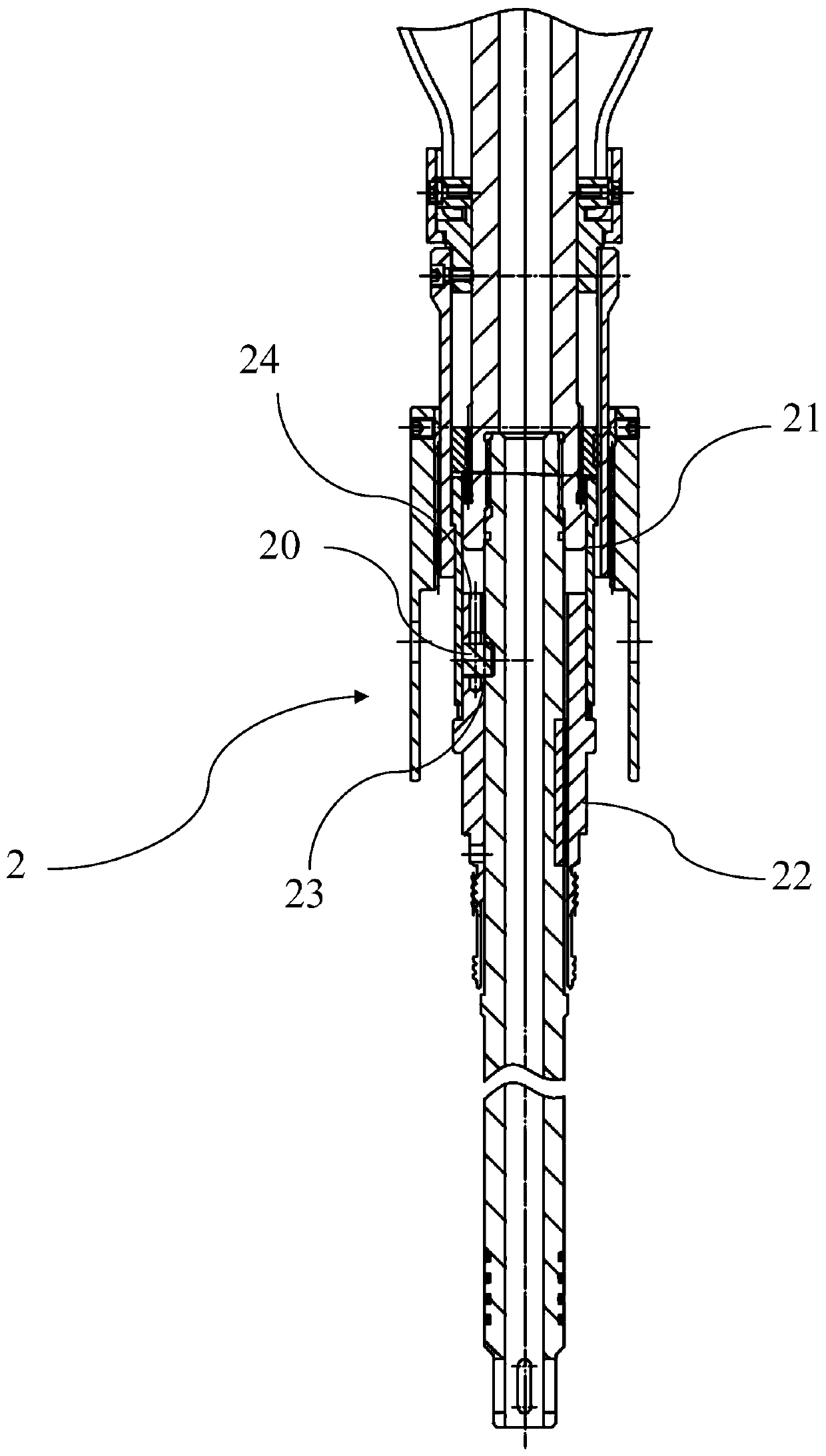

[0036] An exemplary solution of a drillable packer and a matching setting tool according to the present invention will now be described in detail with reference to the accompanying drawings. The drawings are provided to illustrate various embodiments of the invention, but the drawings are not necessarily to scale of particular embodiments and certain features may be exaggerated, removed, or partially sectioned to better illustrate and explain aspects of the invention. public content. Some components in the drawings can be adjusted according to actual needs without affecting the technical effect. Appearances of the phrase "in the drawings" or similar terms in the specification do not necessarily refer to all drawings or examples.

[0037] Certain directional terms used hereinafter to describe the drawings, such as "inner," "outer," "upper," "lower," and other directional terms are to be understood to have their normal meaning and refer to the drawings as viewed normally those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com