A kind of preparation method of polydopamine structural color film

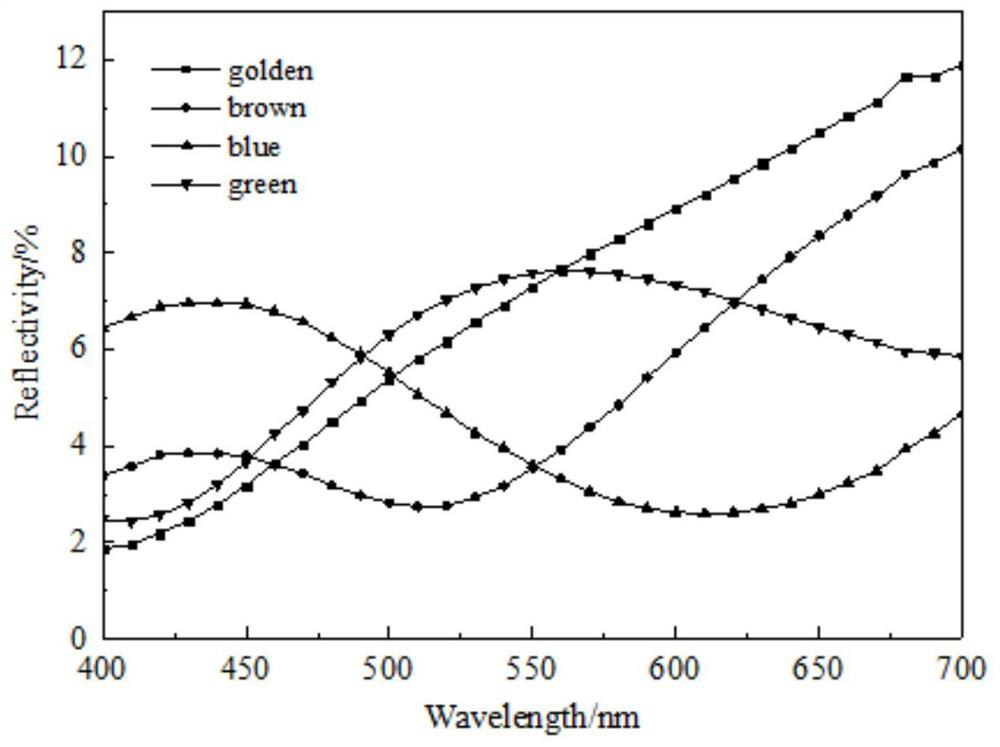

A technology of polydopamine and structural color, which is applied in textiles, papermaking, and fiber processing, and can solve problems such as single color, easy cracking of color film, and poor color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, through the description of the examples, the specific implementation of the present invention, such as the manufacturing process and operation and use methods involved, will be further described in detail, so as to help those skilled in the art to have a more complete and comprehensive understanding of the inventive concept and technical solutions of the present invention. Accurate and in-depth understanding.

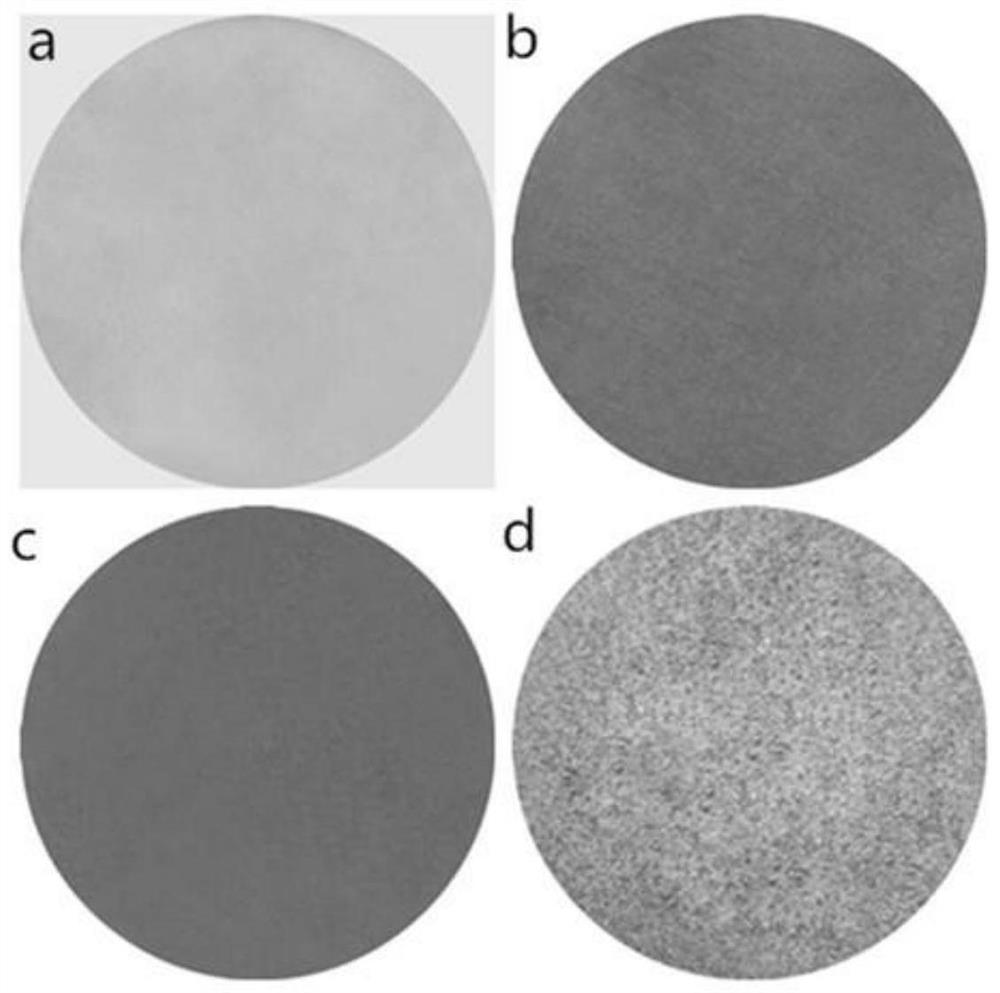

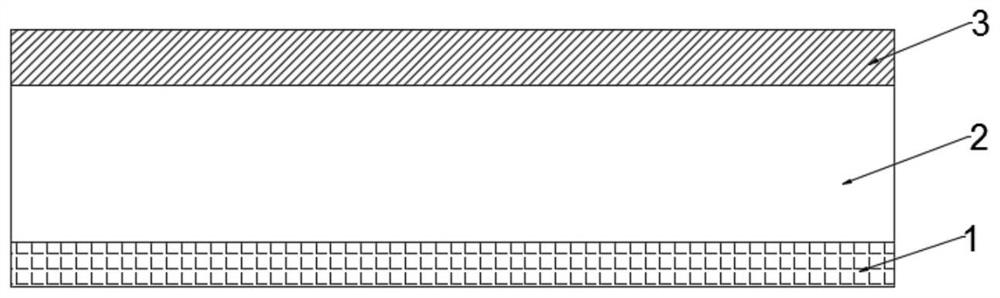

[0029] To solve the problems of easy cracking, poor color fastness and single color of the polydopamine-structured color film in the prior art, a method for preparing a polydopamine-structured color film is provided in the embodiment of the present invention. The preparation method includes the following steps:

[0030] A preparation method of a polydopamine structured color film, comprising the steps of:

[0031] 1) Buffer preparation: add dopamine hydrochloride powder and tris to deionized water, and adjust the pH to 8~8.7 with dilute hydrochloric acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com