Self-weight lifting tool vehicle

A tooling vehicle and vehicle body technology, which is applied in the direction of parallel load-carrying vehicles, motor vehicles, vehicle parts, etc., can solve the problems of low loading efficiency, improve efficiency, solve waste of bending actions, and eliminate jamming or tilting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

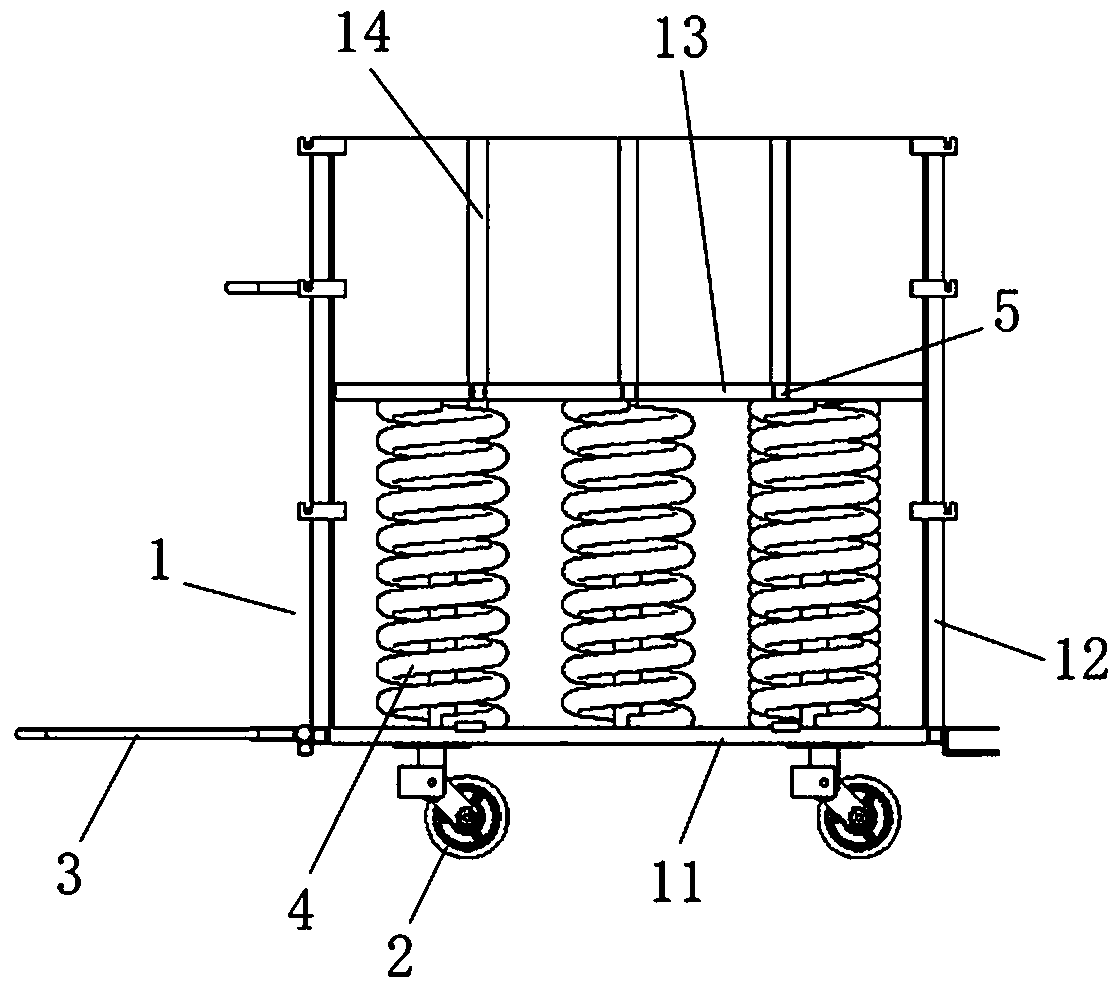

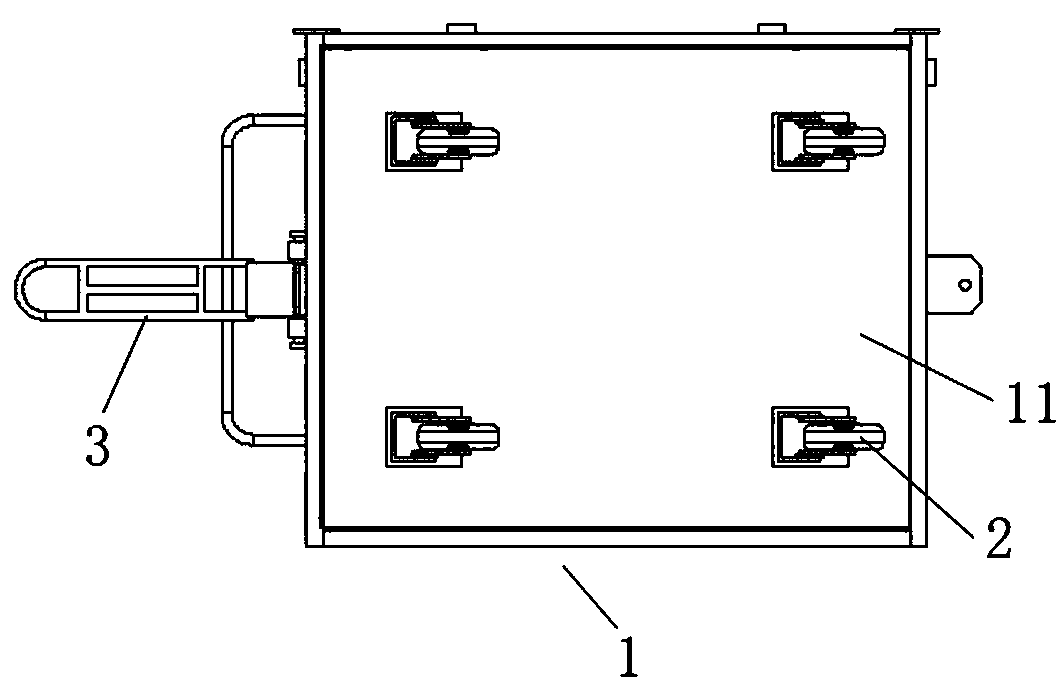

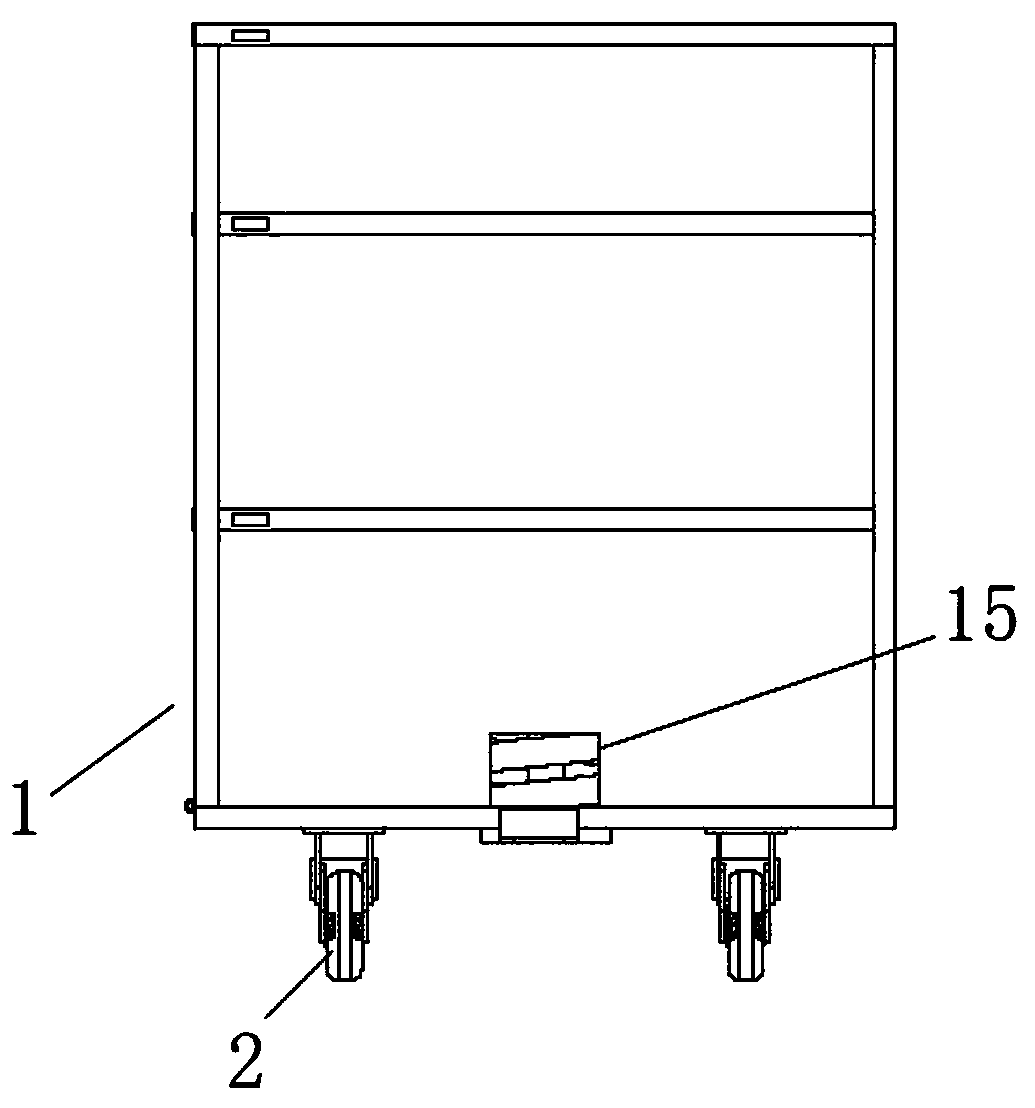

[0024] Such as figure 1 , 2 As shown, the utility vehicle that the present invention proposes self-weight lifting comprises car body 1, and car body 1 is made of fixed base plate 11 and surrounds and is fixed on the side plate 12 on fixed base plate 11, and the opening of car body 1 faces upwards, and the opening of car body 1 A plurality of wheels 2 are installed on the bottom surface, and a traction handle 3 is installed on one side of the fixed base plate 11 . The inner cavity of the car body 1 is provided with a movable floor 13 above the fixed floor 11 , at least one spring 4 is arranged between the fixed floor 11 and the movable floor 13 , and the spring 4 supports the movable floor 13 . When the employee continuously places materials on the movable floor 13, the load on the movable floor 13 gradually increases, the spring 4 is compressed downward, and the height of the movable floor 13 gradually decreases with the compression of the spring 4 until the car body is fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com