A horizontal connection structure of prefabricated concrete double t-slab and its construction method

A technology of prefabricated concrete and horizontal connection, which is applied to the processing of building components, building structures, and building materials. It can solve the problem of weakening the local bearing capacity of the roof, limiting the application range of the slab, and poor lateral stiffness of the rib beam. problem, to achieve the effect of transmitting horizontal force, large bearing capacity and effective horizontal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

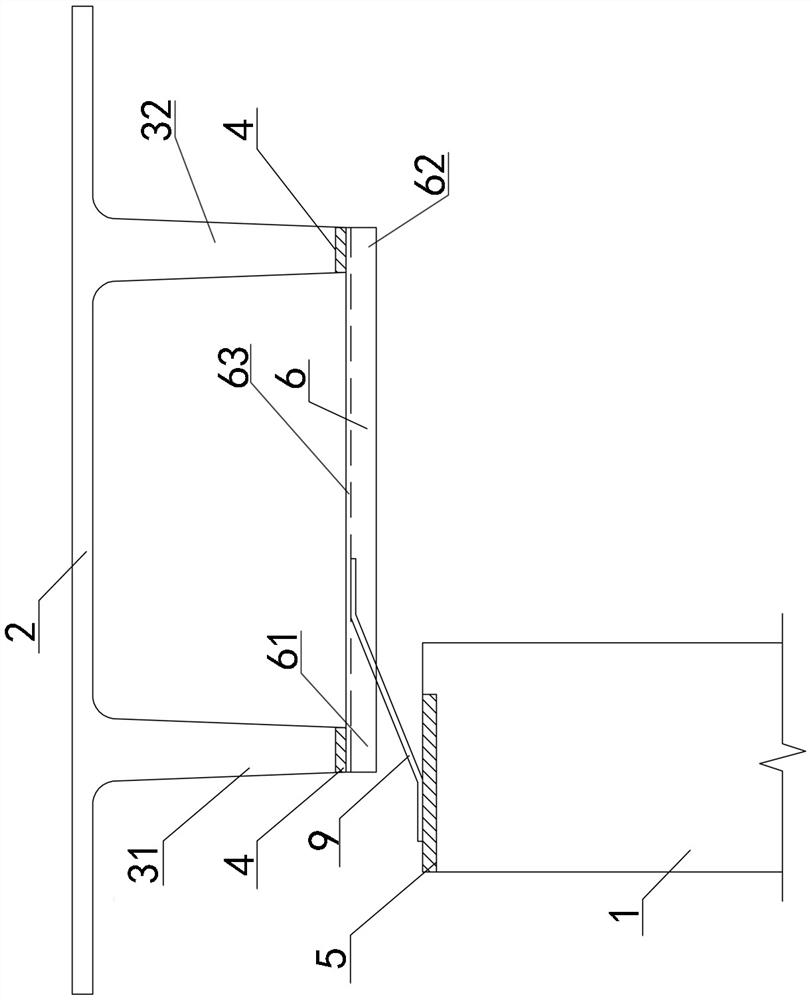

[0041] Example 1 see figure 1 , 3 As shown in -6, when the required horizontal support force is small:

[0042] The horizontal connection structure of this prefabricated concrete double T-slab comprises a double T-slab and a vertical component located below the double T-slab and fixedly connected to it, the vertical component 1 is a column or a wall, and the double T-slab includes The upper horizontal top plate 2 and the lower two rib beams form a π shape with the top plate and the two rib beams.

[0043] The two rib beams include a proximal rib beam 31 close to the vertical member and a distal rib beam 32 away from the vertical member, and the vertical member 1 is located directly below the proximal rib beam 31 .

[0044]A horizontal beam bottom connecting rod 6 is fixedly connected between the bottoms of the two rib beams. The beam bottom connecting rod 6 is vertical to the vertical member 1 in space. The two ends of the beam bottom connecting rod 6 include vertical The p...

Embodiment 2

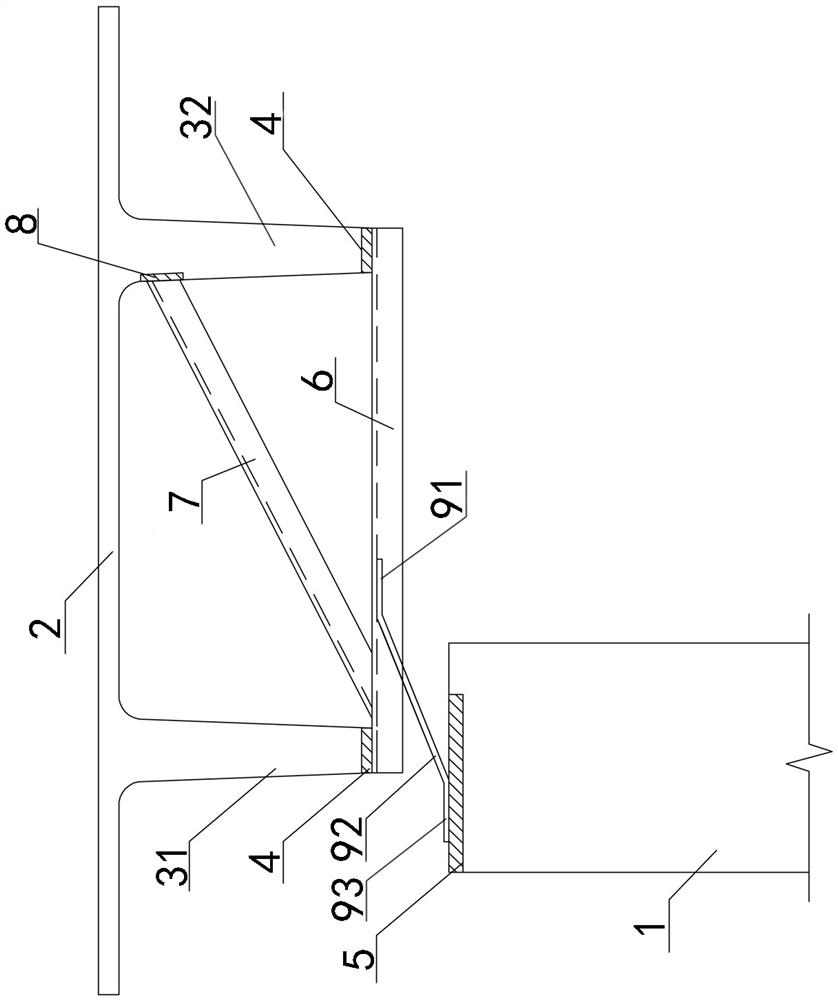

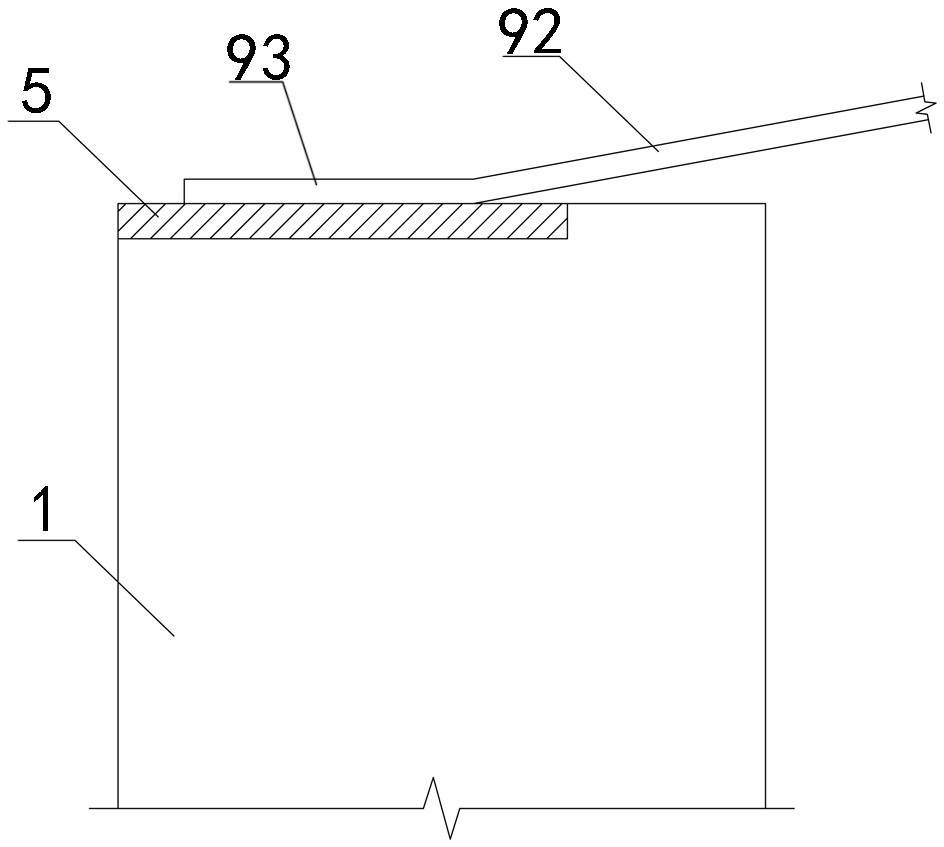

[0048] Example 2 see Figure 2-6 As shown, when the required horizontal support force is large:

[0049] The difference from Embodiment 1 is that the partially closed space truss structure also includes a diagonally braced steel rod 7 arranged along the diagonal in the closed space, and the top of the diagonally braced steel rod 7 is fixed to the distal rib beam 32 Connect, the bottom of the diagonally braced steel rod 7 is fixedly connected with the connecting rod 6 at the bottom of the beam.

[0050] The top of the distal rib beam 32 and the side located in the closed space are pre-embedded with a beam side top embedded part 8, the beam side top embedded part 8 is a vertical steel plate, and the diagonally braced steel rod 7 The top of the beam is fixedly connected to the top embedded part 8 on the beam side, and the bottom of the diagonal bracing steel rod 7 is fixedly connected to the upper side of the proximal end of the connecting rod 6 at the bottom of the beam.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com