Air inlet channel structure and manufacturing method thereof

A manufacturing method and a technology of an air inlet, which are applied in the direction of fuel air inlet, combustion air/combustion-air treatment, engine components, etc., can solve problems such as energy consumption, flow separation method and mechanism complexity, and achieve wide applicability, Realize the effect of flow drag reduction and improve the effect of flow drag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

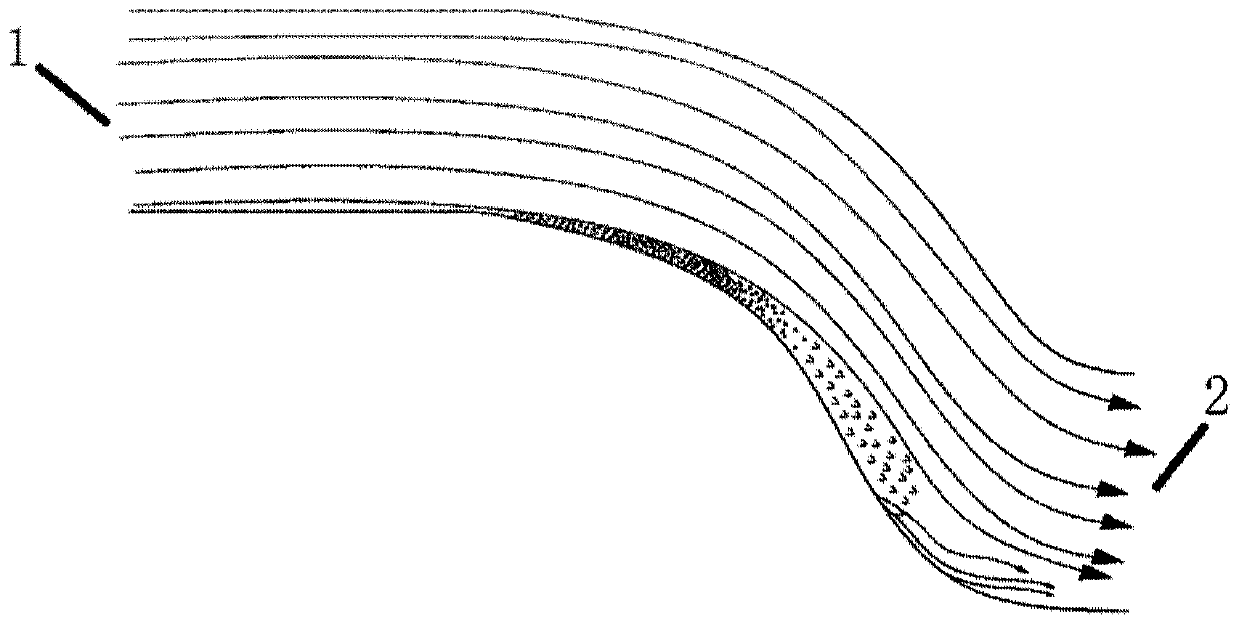

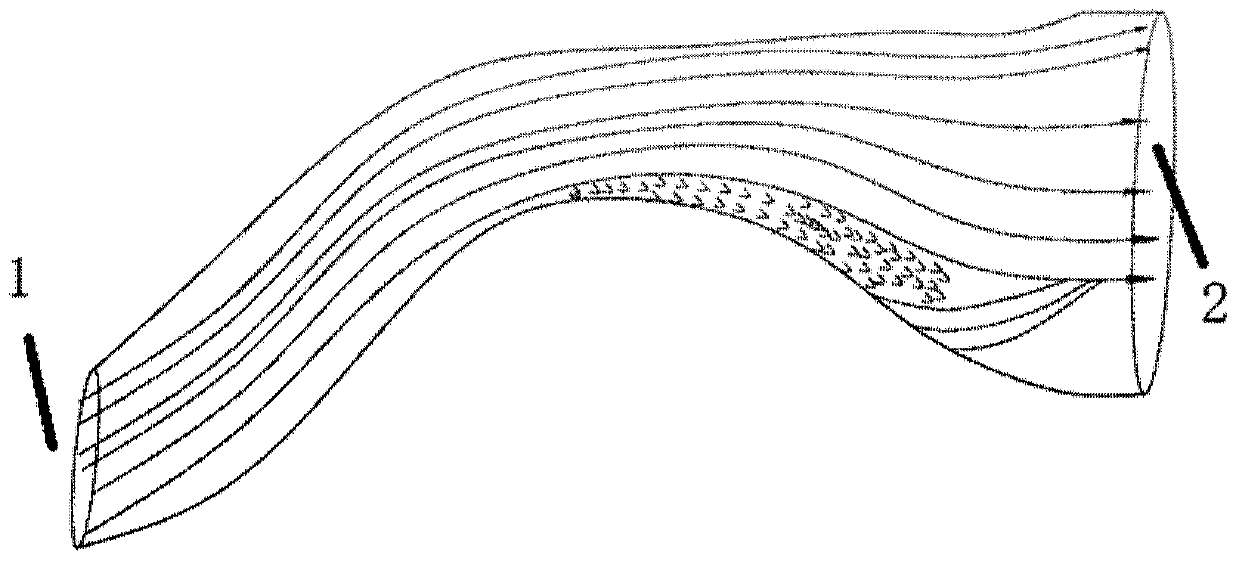

[0034] figure 1 with figure 2 They are the schematic diagrams of the existing typical S-curved inlet structure and the serpentine inlet structure respectively. It can be clearly seen from the figure that this inlet structure has an obvious boundary layer separation zone, and the separation zone will be at the exit. It evolves into a strong vortex distortion flow field, which affects the working performance of the engine body. From the perspective of the principle of boundary layer separation flow control, the purpose is to increase the ability of the boundary layer to resist the adverse pressure gradient. If the energy dissipation of the flow near the wall can be reduced by reducing the flow resistance, the boundary lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com