A Method of Infrared Technology Defect Reconstruction and Feature Extraction Based on Additive Fuzzy

An infrared technology and feature extraction technology, which is applied in the field of defect detection to achieve the effects of accurate division, accurate damage images, and noise information elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

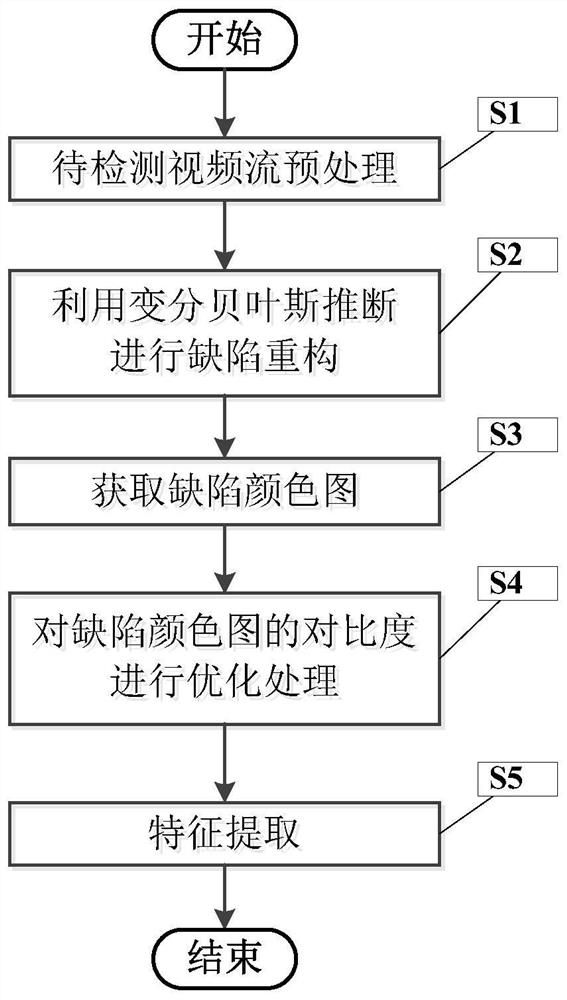

[0078] figure 1 This is the flowchart of the infrared technology defect reconstruction and feature extraction method based on additive fuzzy of the present invention.

[0079] In this embodiment, as figure 1 As shown, the present invention based on the additive fuzzy infrared technology defect reconstruction and feature extraction method includes the following steps:

[0080] S1. Preprocessing of the video stream to be detected

[0081] S1.1, the video stream to be detected is represented as a matrix block as: Among them, N I ×N J represents spatial information, N T Indicates time information;

[0082] S1.2, convert the matrix block into a two-dimensional matrix S through the vector operator Vec();

[0083] S=[Vec(S'(1)),Vec(S'(2)),...,Vec(S'(N T ))]

[0084] in, N IJ =N I ×N J ;

[0085] S1.3. In order to reconstruct different defect information, we start from N T Select N from the frame image that characterize the overall defect of the test piece C frame im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com