An annular inner tube and an installation method thereof

An installation method and annular technology, applied in tire parts, transportation and packaging, reinforcement layers of pneumatic tires, etc., can solve the problems of difficult installation and disassembly, long time consumption, and easy occurrence of danger. The effect of ensuring continued safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

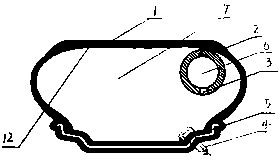

[0021] Example 1: from figure 1 , is made up of cover tire 1, wheel 5, valve 4, is provided with annular inner tube 2 on the inner surface of cover tire 1, and this annular inner tube 2 is provided with inflatable cavity, and annular inner tube 2 is provided with valve 3, and the diameter of annular inner tube is consistent with the diameter of cover tire inner surface Correspondingly, the annular inner tube 2 is supported on the left inner surface or the right inner surface of the inner surface of the tire, and the annular inner tube 2 can support the outer tire in an inflated state.

Embodiment 2

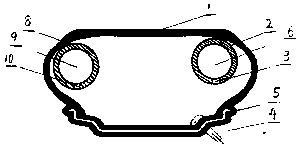

[0022] Example 2: From figure 1 , Figure 11 , is made up of cover tire 1, wheel 5, valve 4, is provided with annular inner tube 3 on the left inner surface of outer tire 1 or right inner surface, and the inner surface of annular inner tube 2 is provided with annular self-repairing rubber layer, and tire repairing rubber layer is a kind of adhesive Adhesive layer, the annular self-sealing rubber adhesive layer is arranged on the inner surface of the annular inner tube, and the annular inner tire 2 is in the state of air leakage. The annular tire repair rubber layer will be blocked by the air pressure in the cavity and bonded to the leak hole of the annular inner tube. The inner tube 2 is provided with an inflation cavity, the annular inner tube 2 is provided with a valve 3, the diameter of the annular inner tube coincides with the diameter of the inner surface of the outer tire, the annular inner tube 2 is supported on the inner surface of the left side of the upper part of th...

Embodiment 3

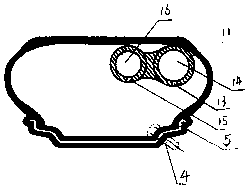

[0023] Example 3: from figure 1 , Figure 8 The inner surface side of cover tire 1 installs annular inner tube 2, and this annular inner tube 2 is provided with inflation cavity, and annular inner tube 2 is provided with air valve, and annular inner tube diameter coincides with cover tire inner surface diameter, can support cover tire under annular inner tube 2 inflated state, The annular inner tube 2 is provided with an annular ply, wherein the annular ply is a folded annular ply, and there is also an interval folded annular ply, wherein there are multiple annular inner tube supports in the outer tire, the inner diameter of the annular inner tube 2 is larger than the inner diameter of the outer tire, and the annular Inner tube of a tube 2 is installed on the left side or right side of cover tire inner surface diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com