Tire type high-speed bulldozer work device

A technology for working devices and bulldozers, which is applied to mechanically driven excavators/dredgers, etc., can solve problems such as reduced operating efficiency, reduced effective torque transmission, and inability to quickly transfer work sites, so as to ensure safety and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

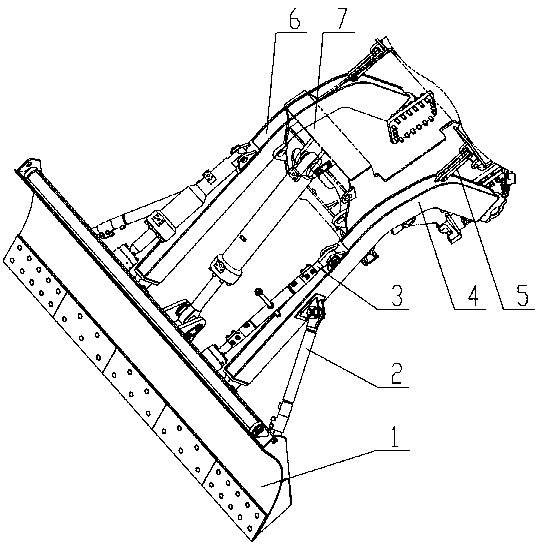

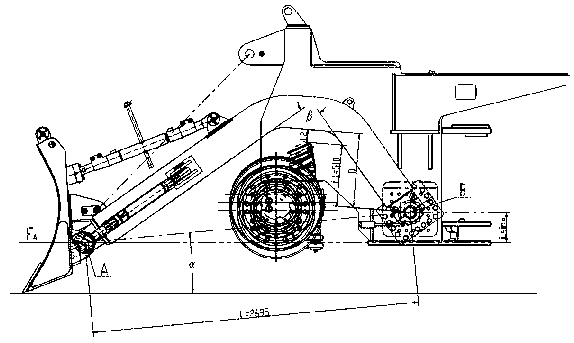

[0024] combine figure 1 As shown, a tire-type high-speed bulldozer working device, the left push arm 4 and the right push arm 6 are symmetrically arranged left and right, the working device 1 is hinged at the front ends of the left push arm 4 and the right push arm 6, and the left push arm 4 and the right push arm 6 The rear end is hinged on the main frame 7. Between the left push arm 4 and the operating device 1, the adjusting rod 3 is hinged, and the left side of the left pushing arm 4, the right side of the right pushing arm 6 and the operating device 1 are respectively hinged with a horizontal bar 2. Locking mechanisms 5 are respectively connected between the left push arm 4 , the right push arm 6 and the host machine 7 .

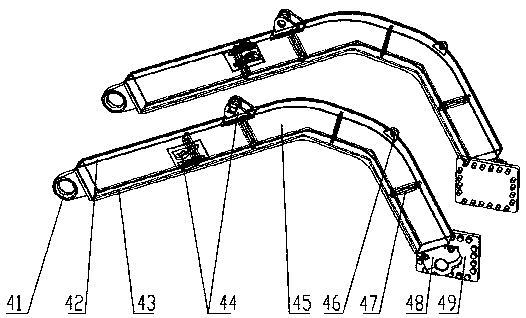

[0025] recombine figure 2 As shown, take the left push arm 4 as an example: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com