A Method of Test Delay Highlighting Critical Gas Pressure and Delay Time

A delay time, gas pressure technology, applied in the application of stable tension/pressure testing material strength, measuring device, suspension and porous material analysis, etc., can solve problems such as casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

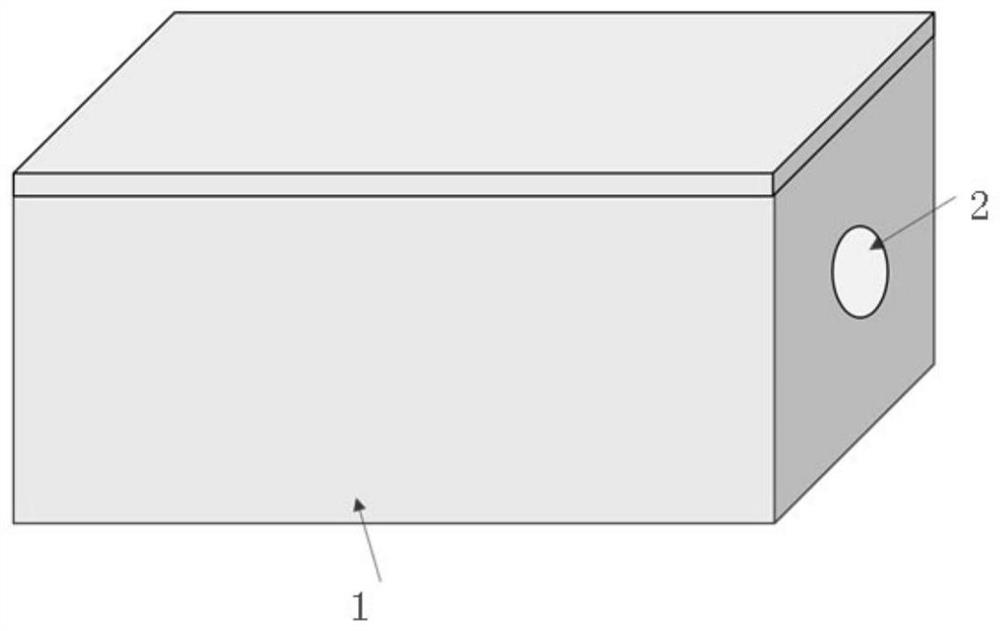

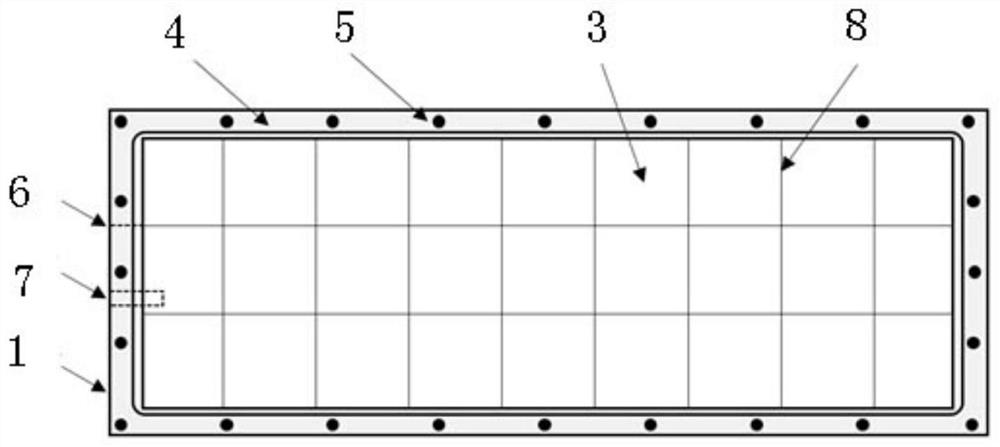

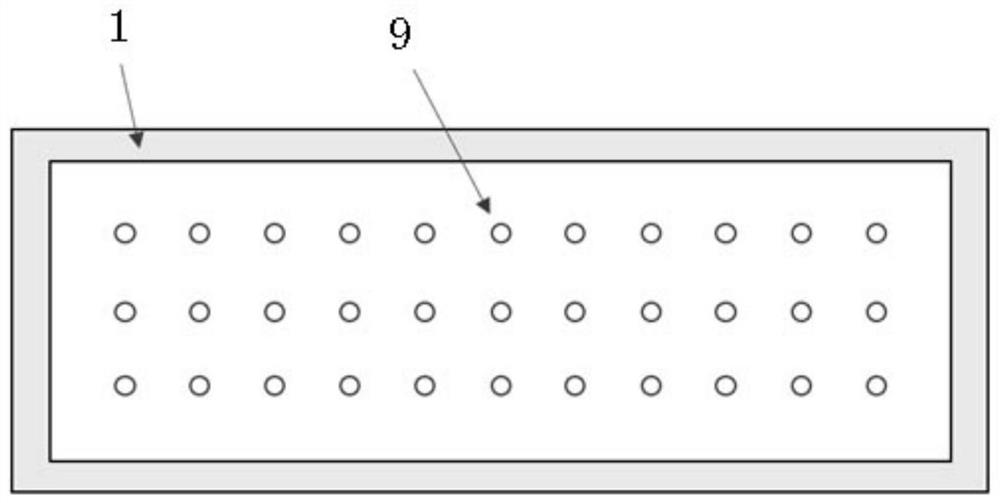

[0034] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0035] The method for testing the critical gas pressure and delay time of delayed outburst of the present invention includes: the preliminary preparation stage, the delayed outburst breeding stage, the delayed outburst induction stage, the end of delayed outburst and the follow-up work;

[0036] The detailed steps are:

[0037] 1a) Carry out on-site investigation by sampling the coal blocks of the outburst coal seam in the coal mine area to be tested, use the coal block samples collected on site to measure the relevant parameters of the outburst coal seam, and determine the test plan;

[0038] 1b) Use a crushing sieve to sieve the collected coal samples into coal particles with a particle size of 0-1mm, add water to the coal particles and stir to make a 6% moisture content coal sample for later use;

[0039] 1c) Put the 6% moisture content coal sample into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com