A kind of aero-engine compressor rotor blind cavity nut automatic tightening device and method

A compressor rotor, aero-engine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low tightening efficiency, invisible tightening process of narrow blind cavity nut, etc., achieve high tightening accuracy and reduce skill requirements and labor intensity, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

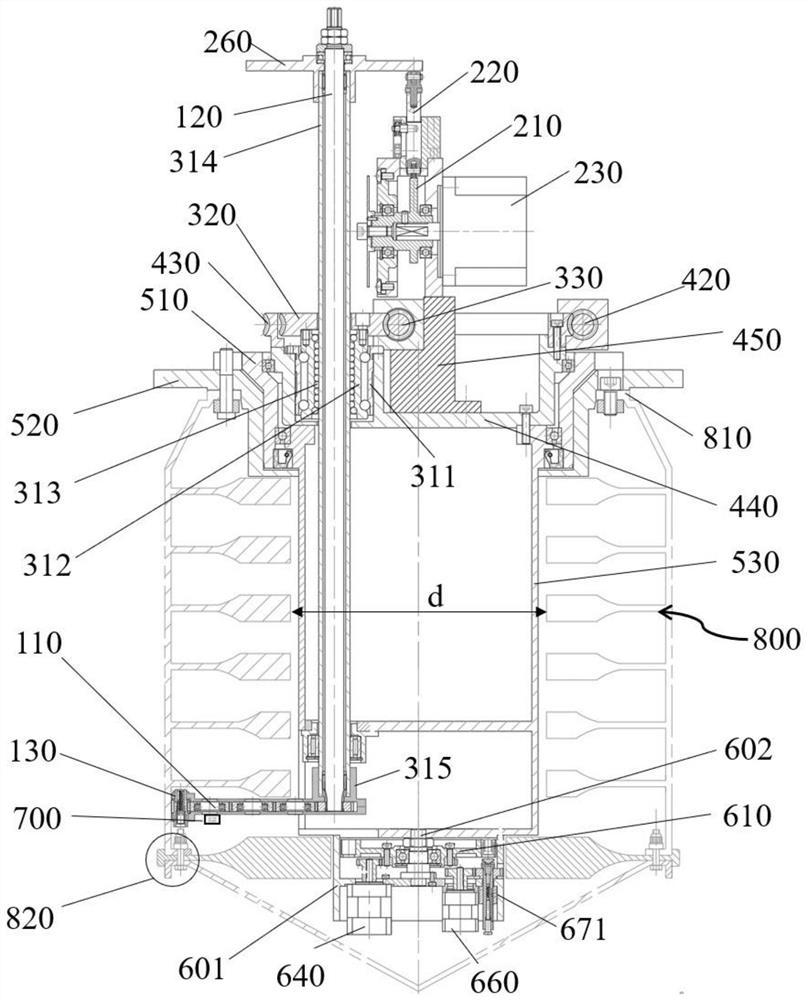

[0061] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it. In this embodiment, the rotor disk to be connected is taken as an example of the third-stage rotor disk to be connected of the compressor, and the automatic nut tightening device provided in this embodiment is installed on the rear flange of the ninth-stage rotor disk.

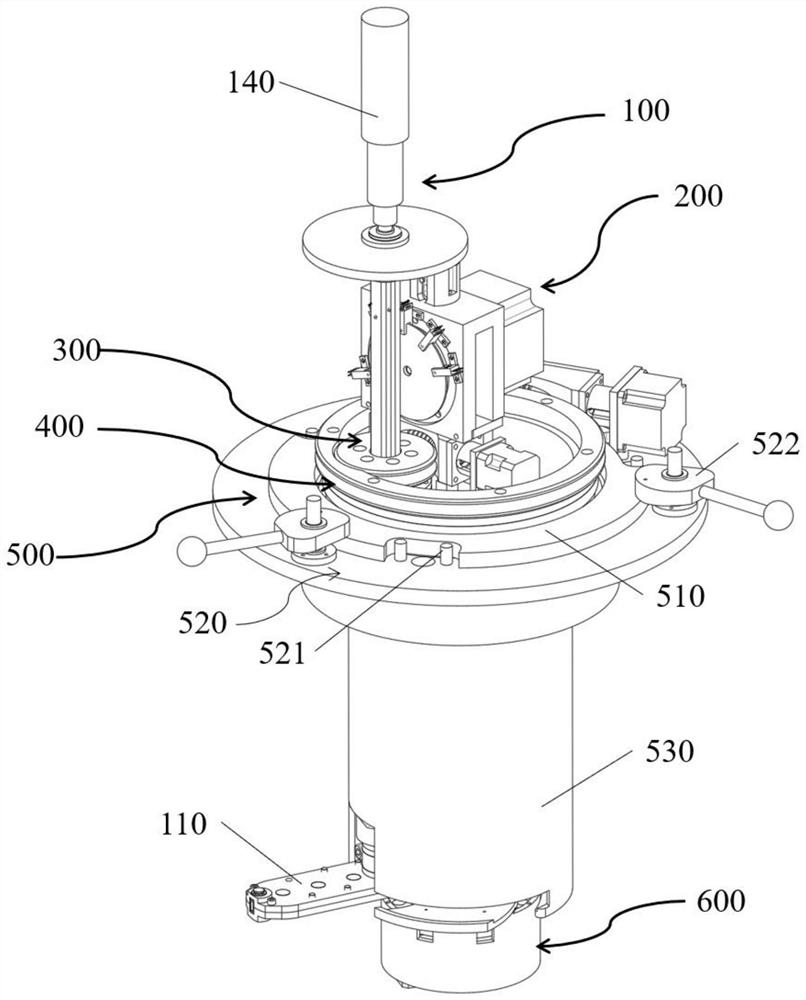

[0062] Such as figure 1 and 2 As shown, the aeroengine compressor rotor blind cavity nut automatic tightening device provided in this embodiment includes an L-shaped tightening mechanism 100, a lifting mechanism 200, an expansion / contraction mechanism 300, a circumferential rotation mechanism 400, a support mechanism 500 and a nut supply mechanism 600.

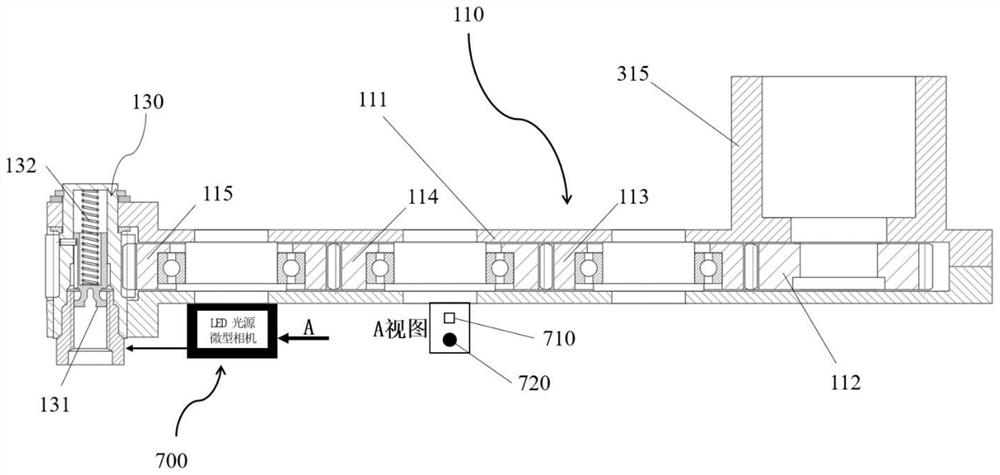

[0063] refer to Figure 1-3 , the L-shaped tightening mechanism 100 is L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com