Film covering curved glass attaching method, shell and electronic device

A curved glass and shell technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of uneven pressure, bubbles between the substrate and the concave surface of the glass, etc., and achieve high bonding yield and uniform appearance , The effect of high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present application are described in detail below, and those skilled in the art will understand that the following embodiments are intended to explain the present application, and should not be regarded as limiting the present application. Unless otherwise specified, in the following examples that do not explicitly describe specific techniques or conditions, those skilled in the art can carry out according to commonly used techniques or conditions in this field or according to product instructions.

[0034] In one aspect of the embodiments of the present application, a method for laminating film-coated curved glass is proposed.

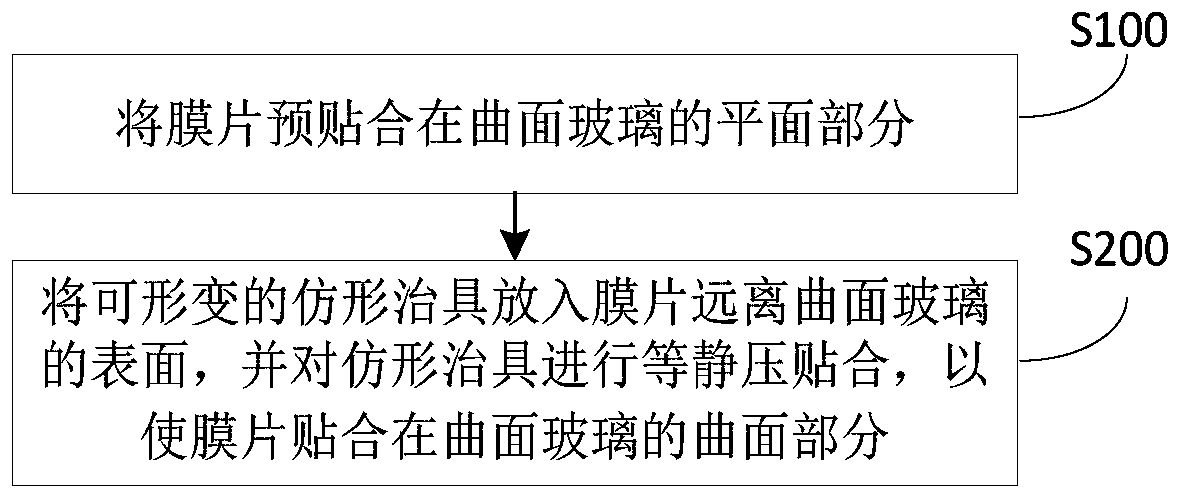

[0035] According to the embodiment of this application, refer to figure 1 , the bonding methods include:

[0036] S100: pre-attaching the film to the flat part of the curved glass.

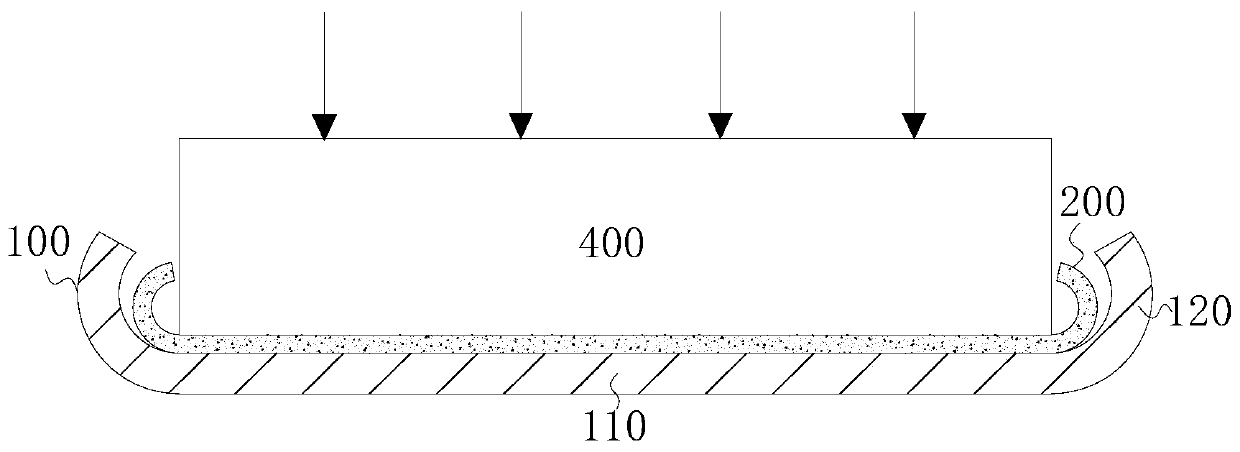

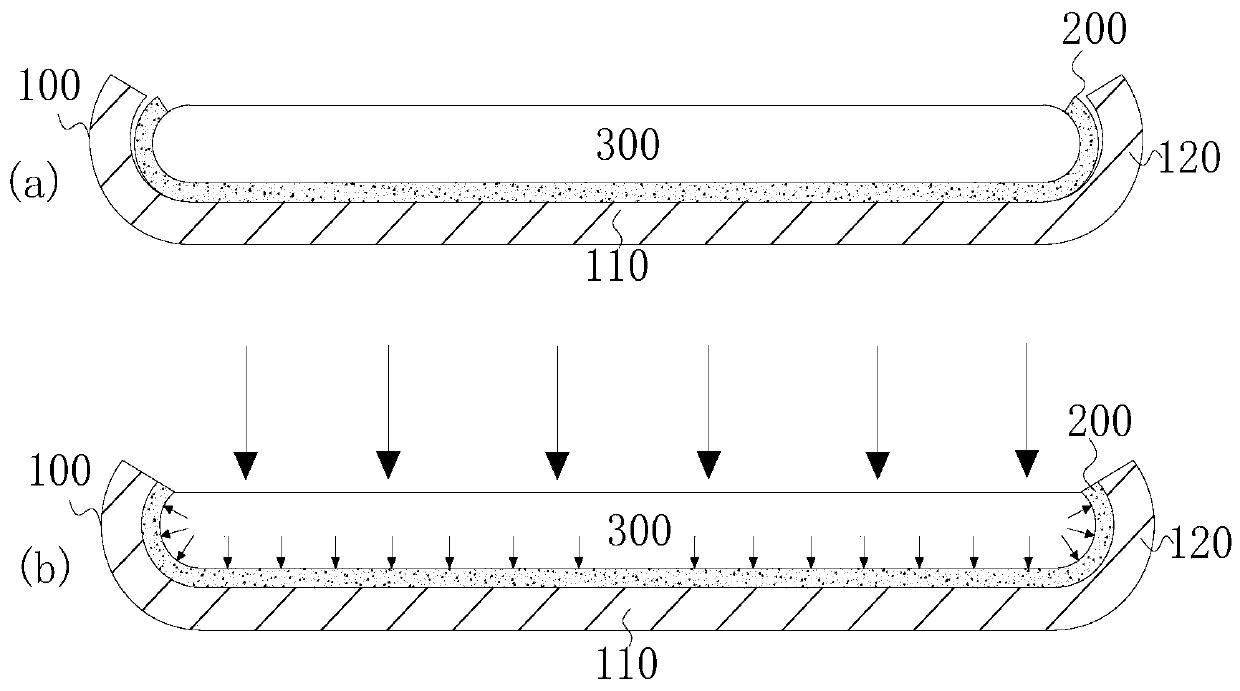

[0037] In this step, the film 200 is pre-attached to the plane part 110 of the curved glass 100. In this way, a part of the film 200 is fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com