A cover bonding device for a curved display panel

A curved surface display and bonding device technology, which is applied to identification devices, material gluing, instruments, etc., can solve problems such as black spots, air bubbles, and fragments, so as to reduce production costs, increase the rate of good bonding products, and increase the utilization rate of cover plates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

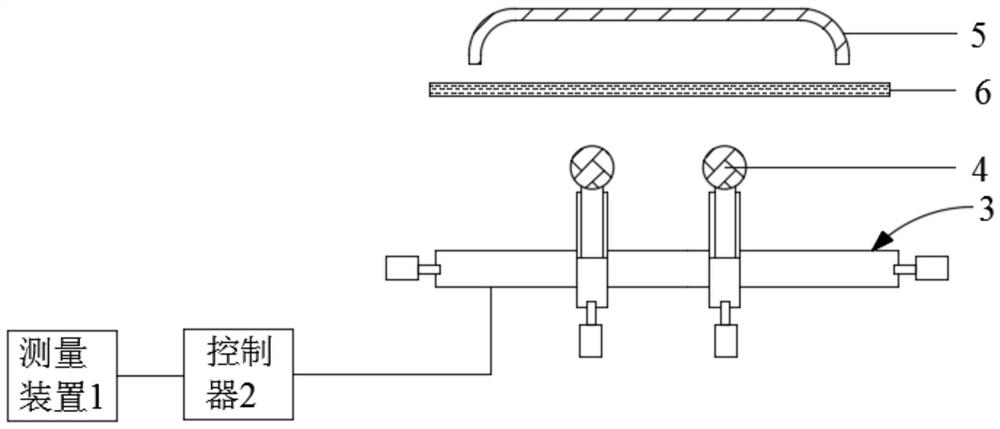

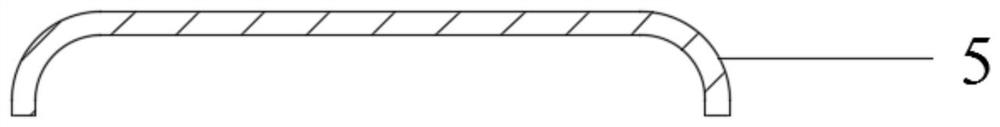

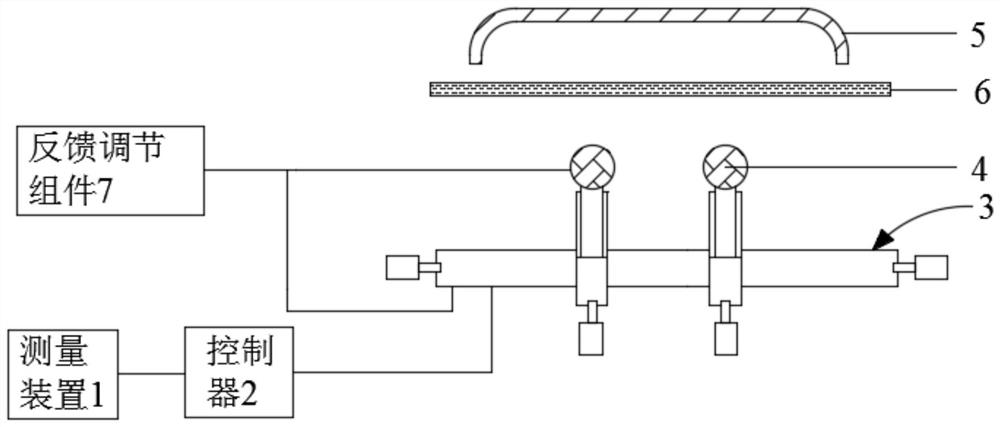

[0021] As mentioned in the background art, the curvature of the curved surfaces on both sides of the cover plate in the prior art is quite different, and there may be technical problems such as air bubbles, black spots or fragments during the bonding process. The inventor found that the reason for this problem is that the current bonding equipment uses a silicone mold to bond the flexible screen to the cover as a whole, and there is a bonding pressure between the flexible screen and the cover. When the two sides of the cover When the curvature difference of the curved surface is too large, if the bonding pressure is too small, it will cause normal bonding on one side and bubbles on the other side; if the bonding pressure is too high, it will cause black spots or fragments on one side, and normal bonding on the other side. In order to solve the above problems, the inventor found that by measuring the curvature data of the curved surface of the cover plate, the supporting and fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com