Multi-degree-of-freedom pipeline bracket structure

A technology with bracket structure and degrees of freedom, applied in the directions of pipe supports, pipe elements, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor pipe radial deflection and flow field vibration, and achieve low cost and good support. , the structure is convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

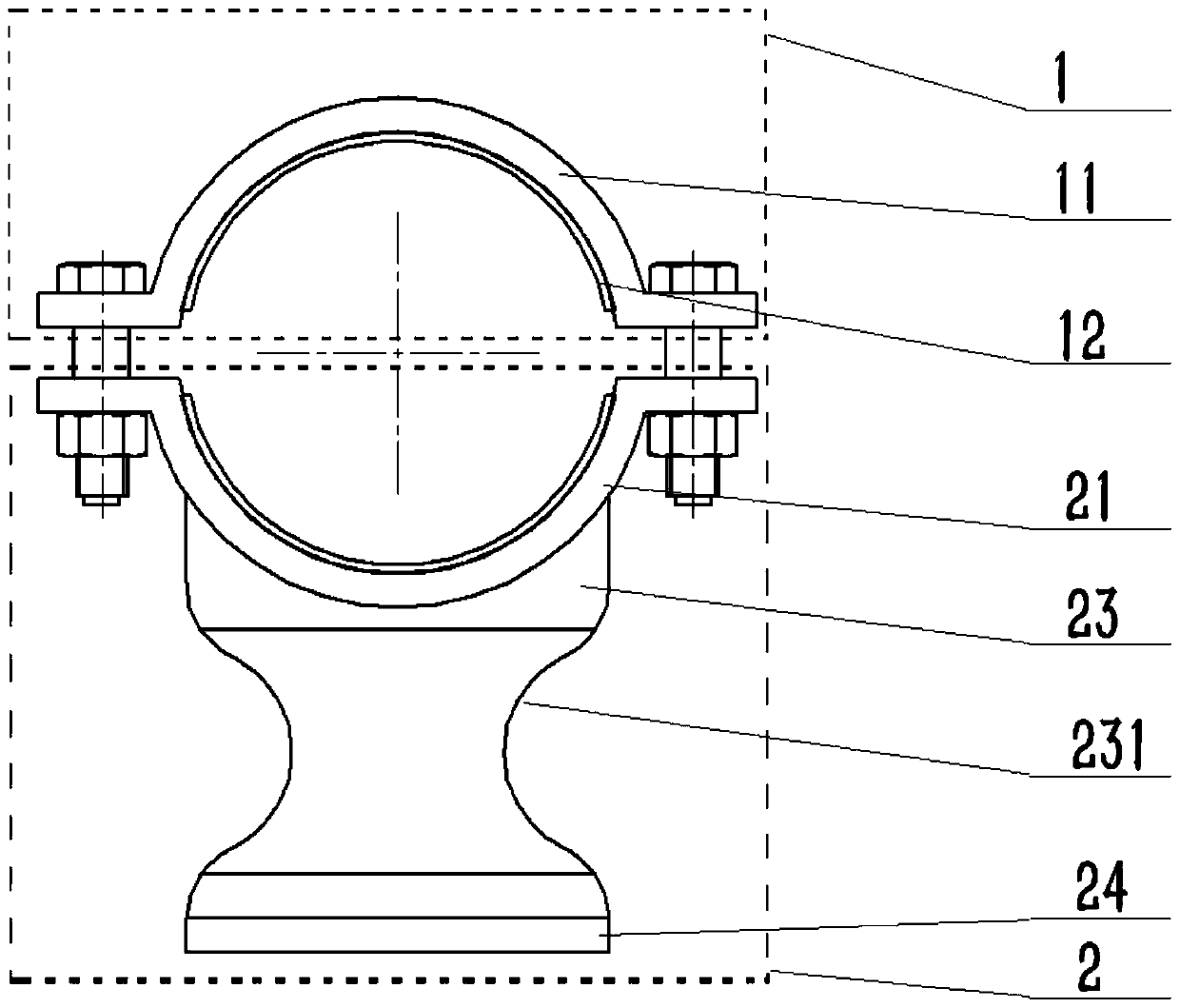

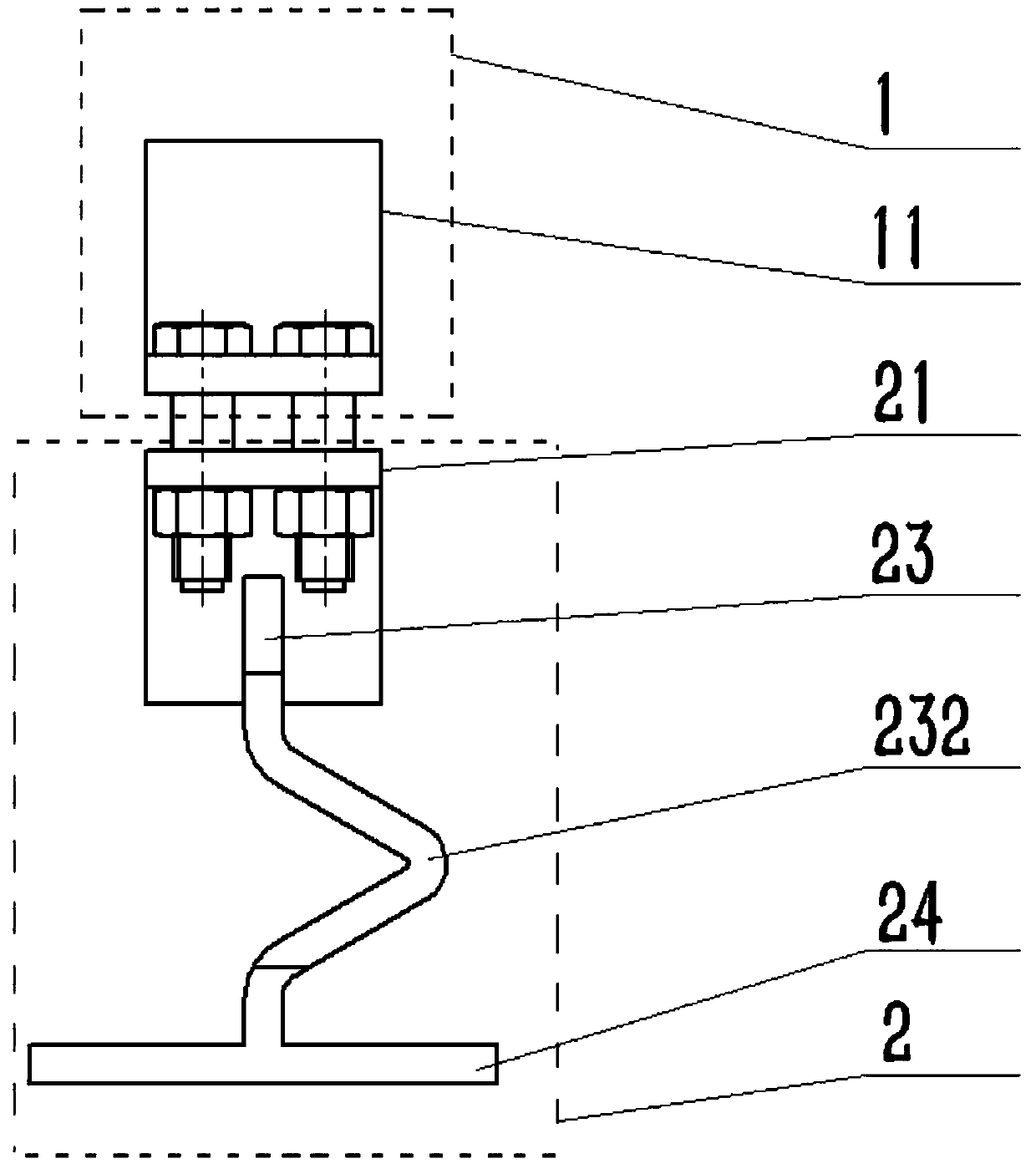

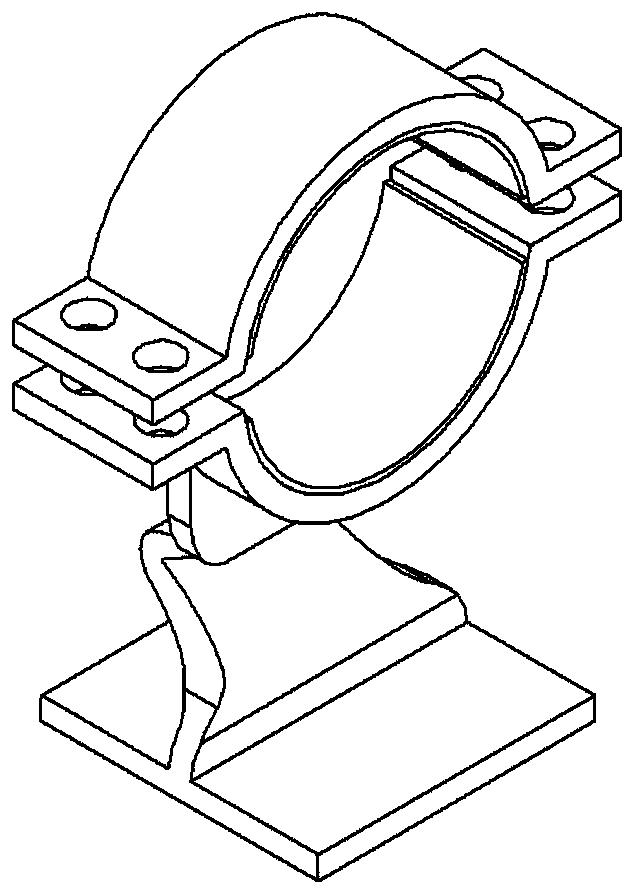

[0019] The structure of a multi-degree-of-freedom pipeline bracket structure of the present invention is as follows: figure 1 As shown, the multi-degree-of-freedom pipeline bracket structure includes a positioning device 1 and a supporting part 2; the positioning device 1 includes a cover plate 11 and a fitting part 12, and the fitting part 12 is in contact with the inner arc surface of the cover plate 11, and the supporting part 2 includes a supporting plate 21, a fitting part 12, an elastic body 23 and a bottom plate 24, the fitting part 12 is in contact with the inner arc surface of the supporting plate 21, one end of the elastic body 23 is fixedly connected with the radial distance of the supporting plate 21, and the bottom plate 24 is in contact with the inner arc surface of the supporting plate 21 The other end of the elastic body 23 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com