A hydraulic cylinder blockage damage detection device

A technology of hydraulic cylinder and detection device, applied in hydraulic and pneumatic fields, can solve problems such as damage, and achieve the effect of detecting the degree of damage, eliminating potential safety hazards, and accurately determining the degree of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

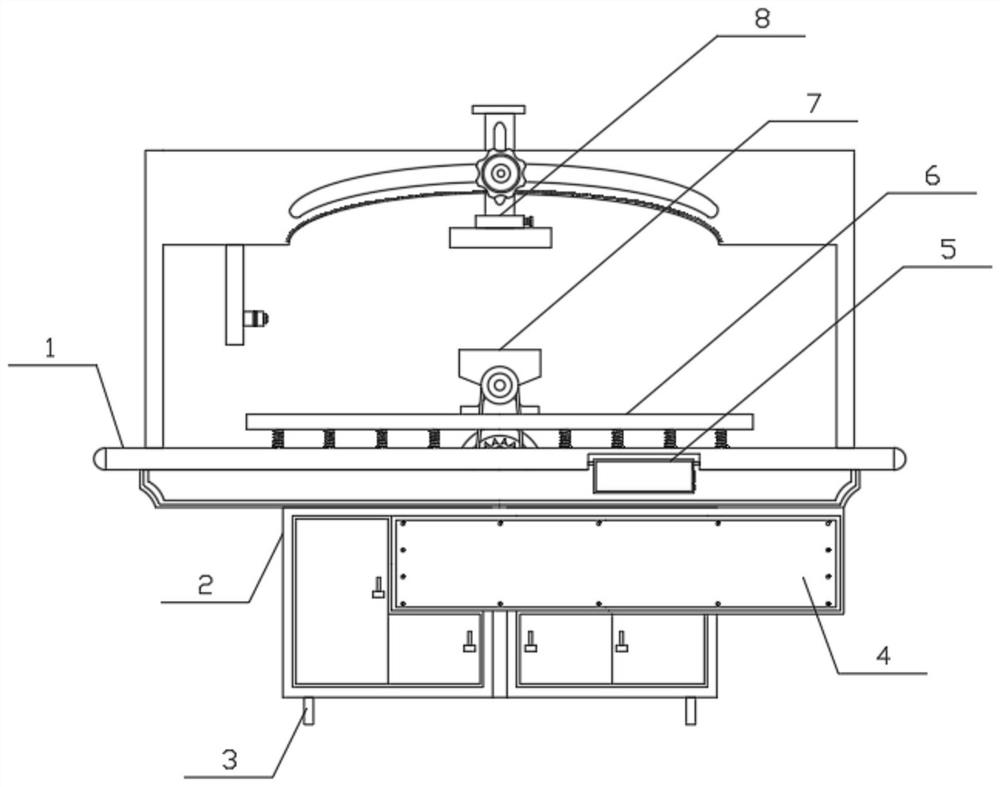

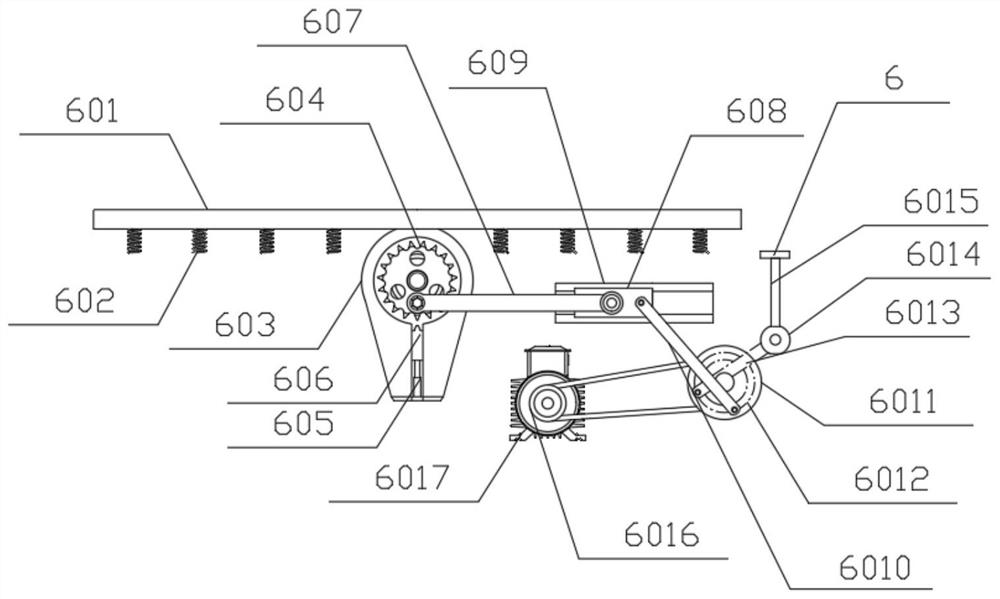

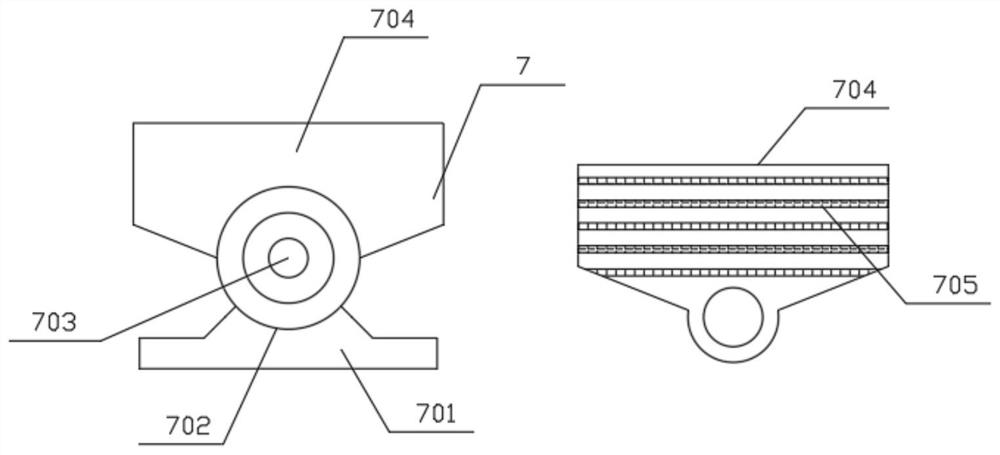

[0023] In this technical solution:

[0024] Tilting mechanism-6, Clamping mechanism-7 Blocking mechanism-8, Support plate-601, Spring-602, Case-603, Gear-604, Electric push rod-605, Limiting block-606, Driven rod-607 , the first slider-608, the slide rail-609, the first linkage rod-6010, the disc-6011, the first transmission wheel-6012, the second linkage rod-6013, the second slider-6014, the round rod-6015 , The second transmission wheel-6016, the motor-6017, the bearing seat-701, the third transmission wheel-702, the screw rod-703, the clamping plate-704, the silicone pad-705, the gantry-801, the chute-802, Slide bar-803, handwheel-804, card slot-805, bottom plate-806, scale teeth-807, infrared sensing device-808 are the substantive innovative components of the present invention.

[0025] The processing table-1, the storage cabinet-2, the foot-3, the cover board-4, and the control panel-5 are the indispensable connecting components for realizing the technical solution of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com