In-service rigid hanger load measurement method

A rigid hanger and load technology, which is applied in the direction of measuring force, measuring device, and testing of mechanical parts, can solve the problems of limited working life of strain gauges, unfavorable workload of pipelines, etc., and achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

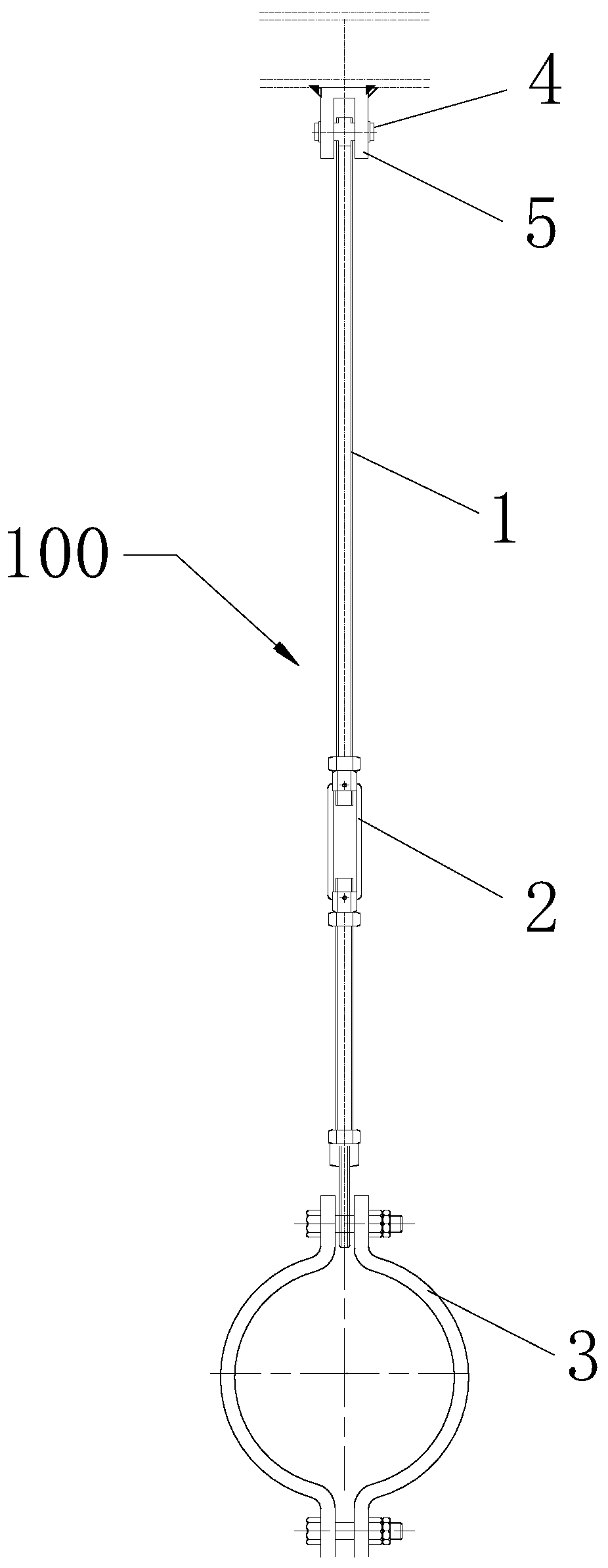

[0037] See attached figure 1 It is a schematic diagram of the structure of the rigid hanger 100, and the rigid hanger 100 is mainly assembled by the hanger rod 1, the connecting piece 2, the pipe clamp 3, the nut, the gasket, the pin shaft 4, and the like. The upper end of the boom 1 is connected with the rooting steel structure through a gasket and a nut or connected with the lifting lug 5 through a pin 4 . The gasket is a hemispherical gasket, which can ensure that the boom 1 can rotate freely at a small angle. The lower end of the boom 1 is connected with the pipe clamp 3 through the pin shaft 4, and the pipe clamp 3 is used to support the pipe. The above connection method can ensure that the rigid hanger 100 only bears the axial tension and does not bear the action of bending moment in any direction during normal operation.

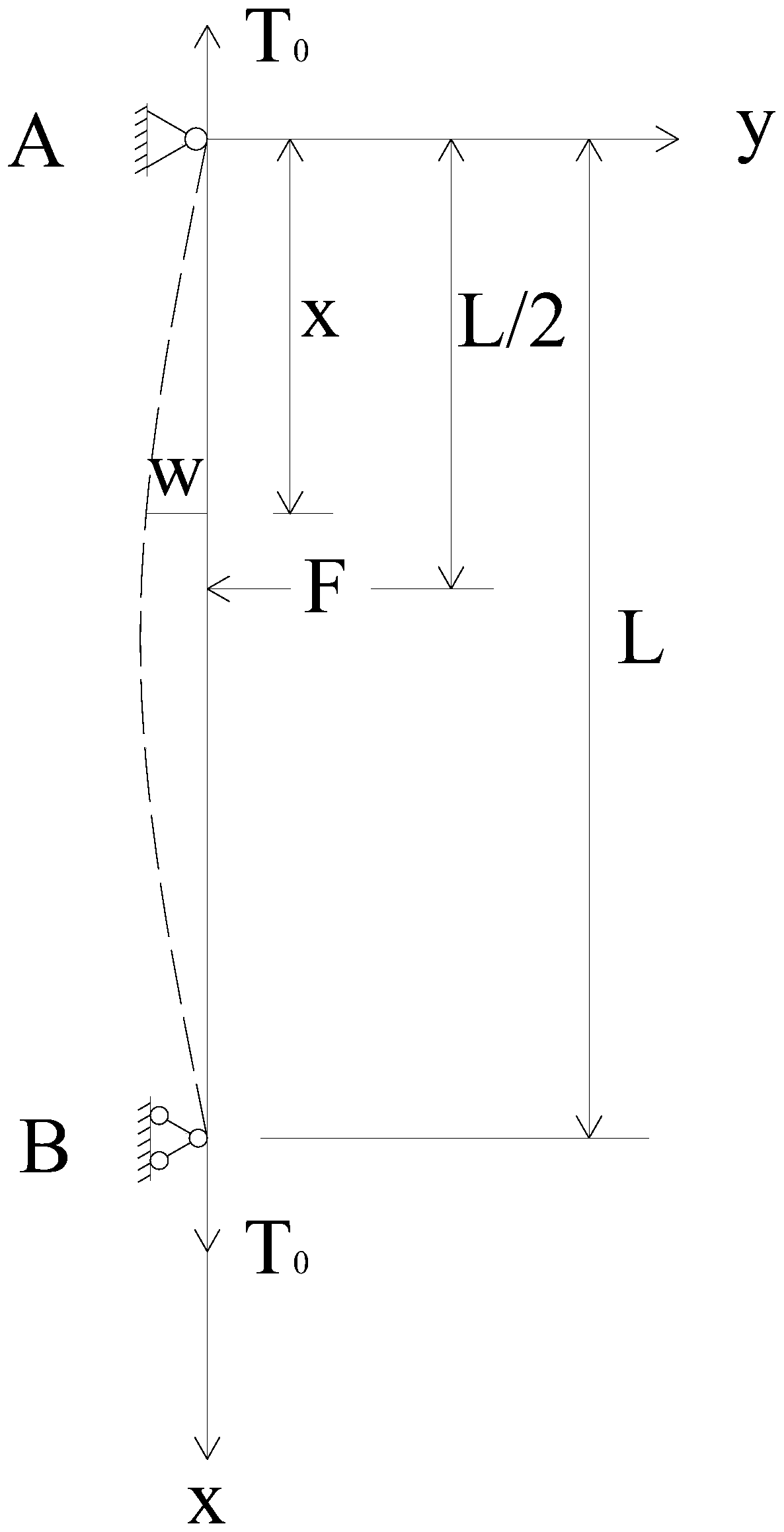

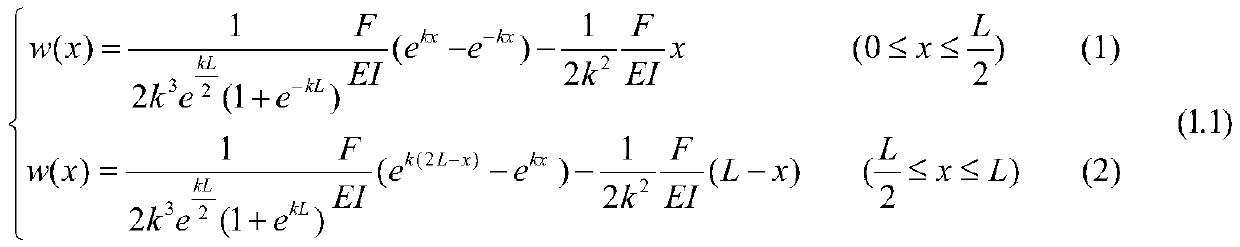

[0038] For measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com