A crack detection device for cylindrical parts

一种裂纹检测、零件的技术,应用在柱状零件的裂纹检测装置领域,能够解决工作效率低下、扫描范围不确定、扫描漏洞区域等问题,达到保证扫描质量和、减少人工作业、提高工作效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

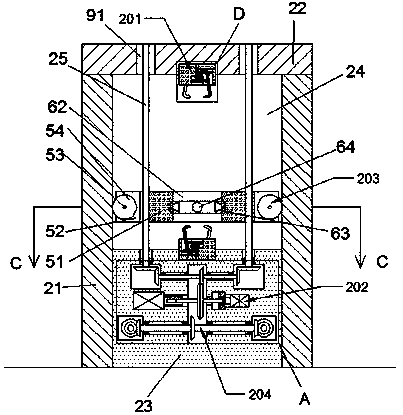

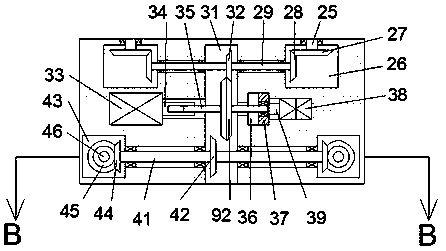

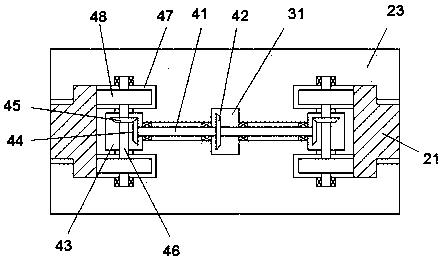

[0020] Combine below Figure 1-Figure 6 The present invention will be described in detail. For the convenience of description, the orientations mentioned below are now specified as follows: figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0021] The present invention relates to a crack detection device for cylindrical parts, which is mainly used in the process of parts detection. The invention will be further explained below in conjunction with the accompanying drawings of the invention:

[0022] The crack detection device for columnar parts according to the present invention includes two uprights 21, the upper ends of the two uprights 21 are fixedly connected with a beam 22, and two through holes 91 are provided on the beam 22. A detection cavity 24 is provided between the beam 22 and the column 21. The front and rear ends of the detection chamber 24 are connected to the outside. The detection chamber 24 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com