A method and device for detecting die-cutting quality of transparent printed matter

A printing quality technology, applied in the field of die-cutting quality detection of transparent printed matter, can solve the problems of inability to clearly judge the die-cutting quality at the junction of the label area and the backing paper area, and poor detection results, so as to improve the quality detection of die-cutting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

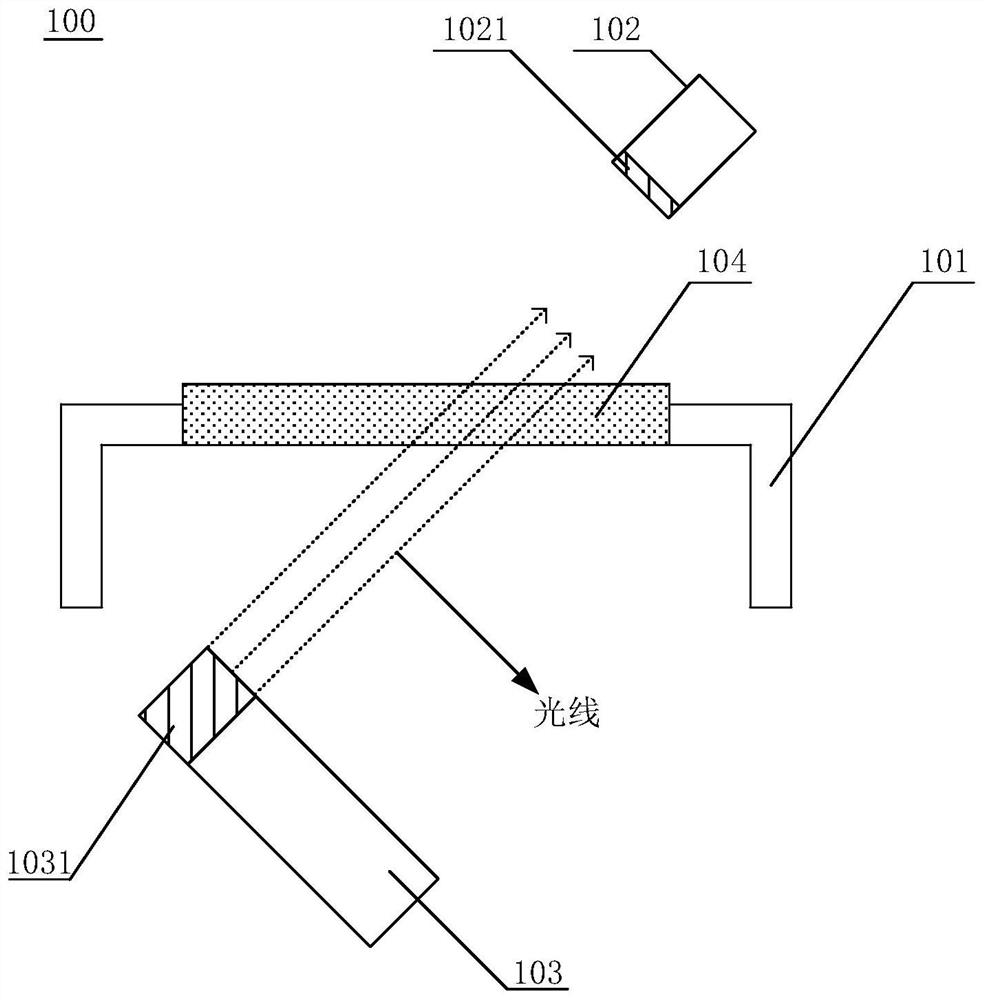

[0058] First combine the following figure 1 The architecture of the die-cutting quality inspection system applicable to the embodiment of the present application is introduced.

[0059] Please refer to figure 1 , which exemplarily shows a structural schematic diagram of a transparent die-cutting quality inspection system applicable to the embodiment of the present application. The system 100 may include a detection platform 101 , a camera 102 and a light source 103 . Wherein, the detection platform 101 can be used to place the printed matter 104; the camera 102 can be arranged on the upper side of the detection platform 101, and the lens 1021 of the camera 102 faces the front of the printed matter 104; the light source 103 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com