An optical coupling microstructure device

A technology for coupling devices and microstructures, which is applied to instruments, electrical digital data processing, and input/output processes of data processing. cost, the effect of improving the touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

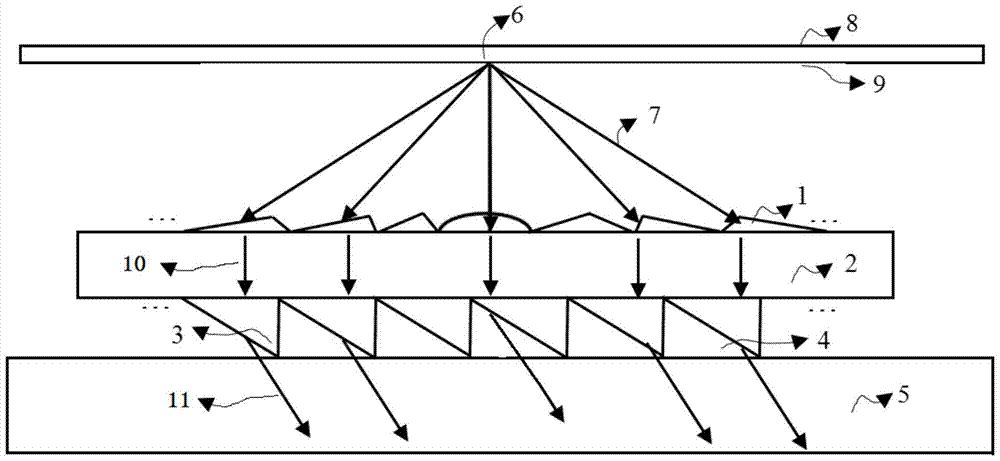

[0038] This embodiment provides an optical coupling microstructure device, such as figure 1 shown, including:

[0039] a first base layer 2;

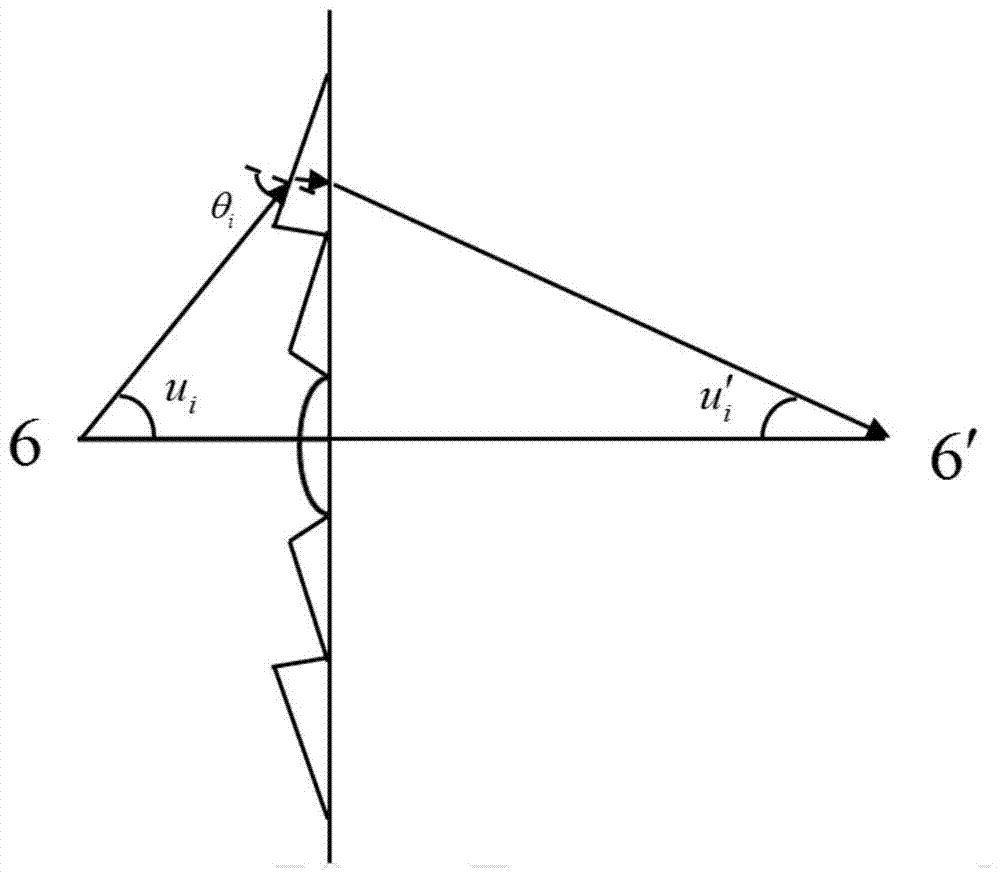

[0040] Fresnel microstructure layer 1, which is arranged on the first surface of the first base layer, for refracting the light 7 incident on the Fresnel microstructure layer to be perpendicular to the direction of the first base layer the first parallel light 10; and

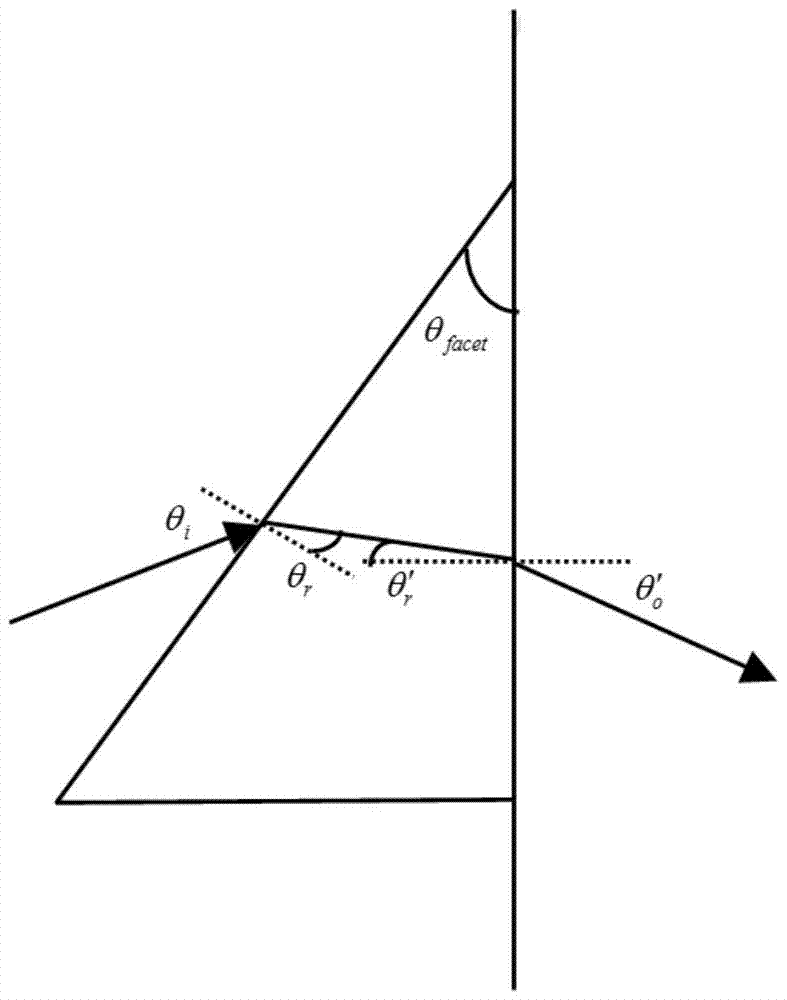

[0041] Refracting optical path microstructure layer 3, which is arranged on the second surface of the first base layer opposite to the first surface, for refracting the first parallel light to form a certain angle with the device 5 to be coupled The second parallel light 11.

[0042] The signal light source 6 is arranged on the diffuse reflection surface 9 of the PCB 8 and directly above the center of the Fresnel microstructure layer. The signal light source can be an infrared LED with a lower cost. Between the PCB board and the Fresnel microstructure layer is an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com