Collimating device of optical sensor, and x-ray flat panel detector

An optical sensor and substrate technology, applied in the field of optical sensors, can solve the problems of complex preparation process of microlenses, difficulty in large-area production, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

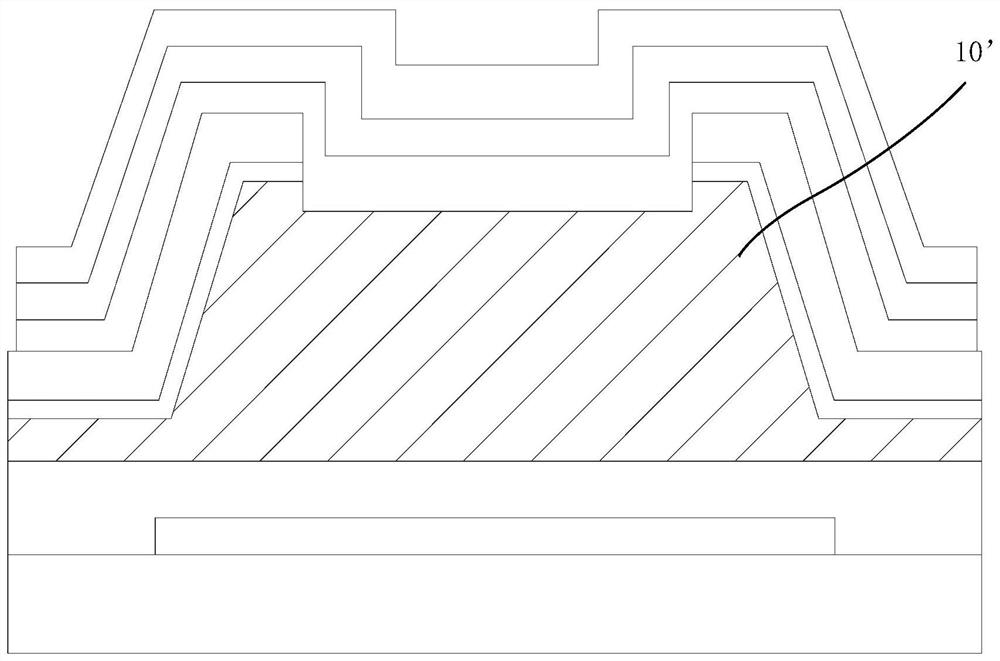

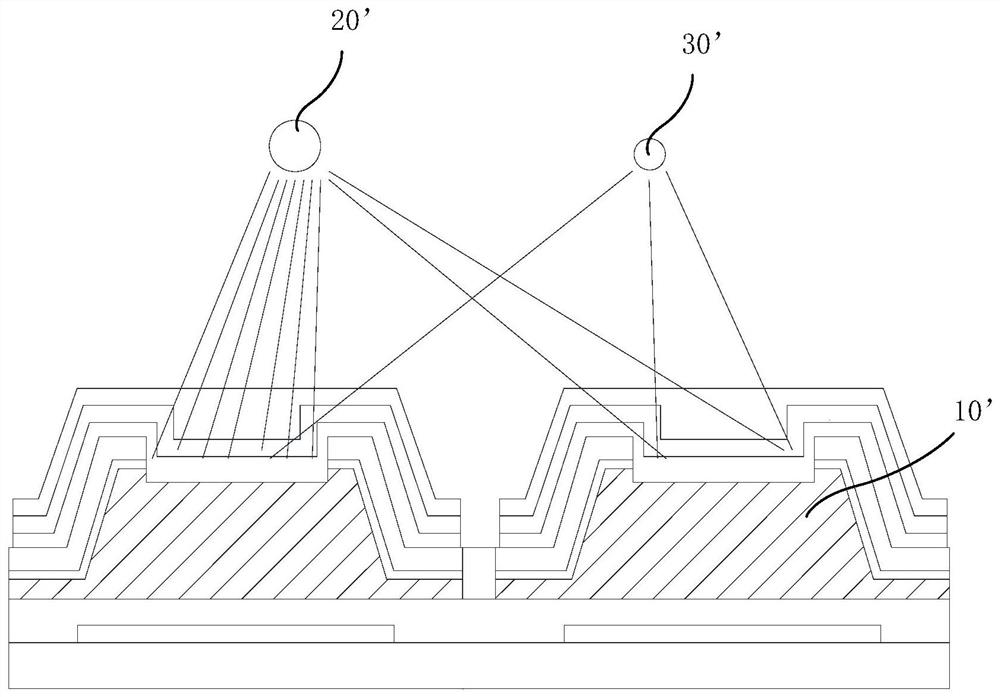

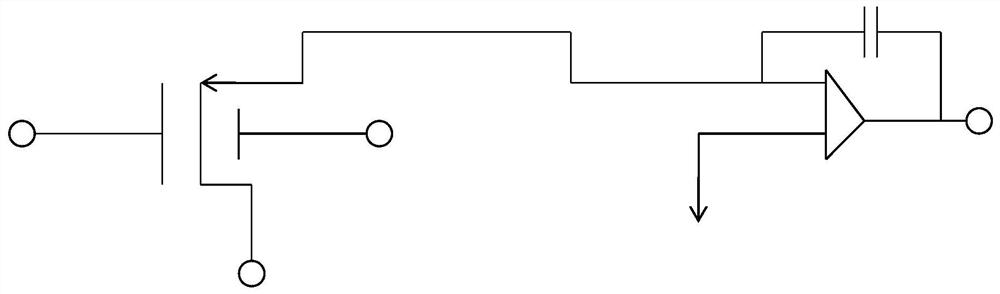

[0035] like Figure 4 Shown, an optical collimating device of the present invention provides a sensor comprising an optical sensor body 10; a first substrate 20 and second substrate 30, the first substrate 20 and second substrate 30 corresponding to the setting, the adhesive is made, easy to process, reduce production costs. Three black matrix, namely: a first black matrix 40, a second black matrix 41 and the third black matrix 42, the first black matrix 401 disposed on a first through hole 40, the second black matrix 41 provided on the second through hole 411, a third black matrix 421 is provided on the third through-hole 42. The first through hole 401, the center channel of the induction sensor and the optical center of the body 411 and the second through hole 421 coincides with the third through-hole. It plays a black matrix for shielding than the rest of the channel induced effects, effective control of the angle of incidence of light.

[0036] The black matrix structure of the...

Embodiment 2

[0045] like Figure 5 with Image 6 As shown in Example 1 is different from, another configuration collimating means of the present embodiment provides an optical sensor, wherein the first substrate 20 and second substrate 30 stacked in the optical sensor 10 of a body side, the first substrate main body 20 close to the optical sensor 10 is provided.

[0046] Compared to the embodiment, the collimator device in Example 2 requires only two substrates, simplify processing steps, improve production efficiency, to save material.

[0047] Preferably, the thickness of the first substrate 20 is 0.1 0.2mm ~, thickness of the second substrate 30 is 0.4 ~ 0.7mm, the length of the channel of the photoreceptor 35 ~ 40μm, the length of the second through-hole 411 of the first through hole 401 ratio: 4: 7 to 5: 6, the second through hole 411 and the third through-hole 421 of the length ratio: 4: 7 to 5: 6.

Embodiment 3

[0049] The present invention also discloses a flat panel x-ray detector, such as Figure 7 Shown, optical sensors and collimation apparatus of Example 2 as an example, x-ray flat panel detector includes a scintillator 30 is connected to the second substrate 80, in order to avoid possible light source 81 is incident into the second through hole 411, a thickness of the second substrate 30 with the scintillator becomes required a large thickness body 80 becomes large; at the same time avoiding the third through hole 421 obliquely incident light enters the sensor, the thickness of the second substrate 30 to be considered a second the thickness and size of the through hole 411 of the first substrate 20. The thickness of the first substrate 20 as small as possible, to avoid oblique light intrusion sensor; a second substrate 30 as thick as possible. Preferably, the thickness of the first substrate 20 is 0.1 0.2mm ~, thickness of the second substrate 30 is 0.4 ~ 0.7mm, the length of the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com