High-strength automobile luggage rack, and a preparation method and equipment thereof

A car luggage rack, high-strength technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of insufficient structural strength and troublesome use of the car luggage rack, and achieve good wire tightening effect and preparation The method is reasonable and effective, and the effect of strong connection and installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

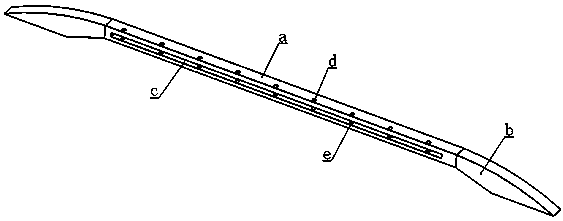

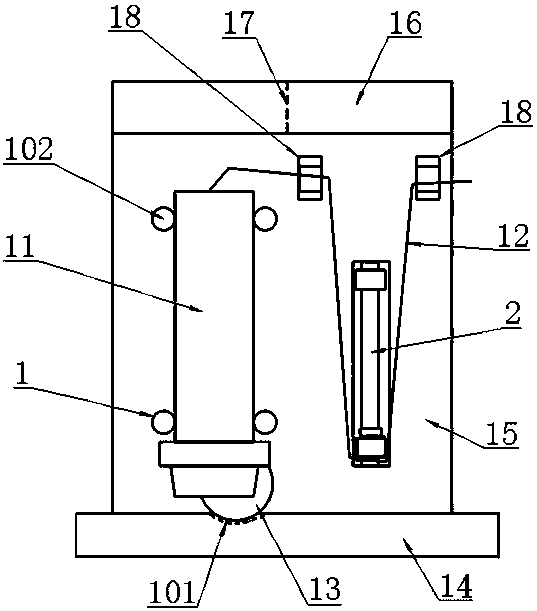

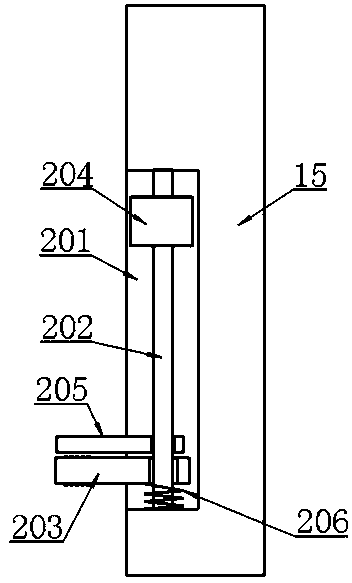

[0028] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Figure 6 As shown, a high-strength automobile luggage rack includes a longitudinal beam main body a, which is respectively arranged at both ends of the longitudinal beam main body a and is screwed to two installation blocks b installed on the outer surface of the roof, and is arranged on the said longitudinal beam main body a. The installation groove c on the inner side of the longitudinal beam main body a and used to install the luggage rack beam, the screw hole d on the upper tank body plate of the installation groove c, and the screw hole d on the lower tank body plate of the installation groove c slot e, the length of the installation slot c is shorter than the longitudinal beam main body a.

[0029] In this embodiment, the two longitudinal beam main bodies a are parallel to the forward direction of the vehicle and arranged on both sides, and the two ends of at least two luggage rack beams are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com