High-strength wood-plastic composite material

A wood-plastic composite material and high-strength technology, which is applied in the field of wood-plastic composite materials, can solve problems such as insufficient structural strength, and achieve the effects of high structural strength, reasonable and effective preparation methods, and convenient and quick mixing and stirring operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

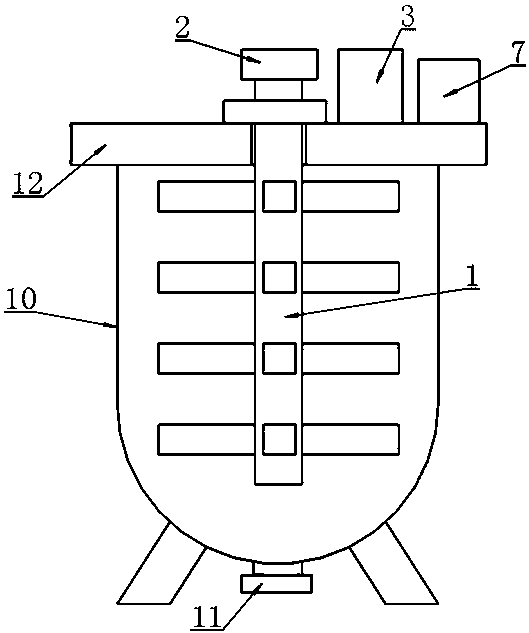

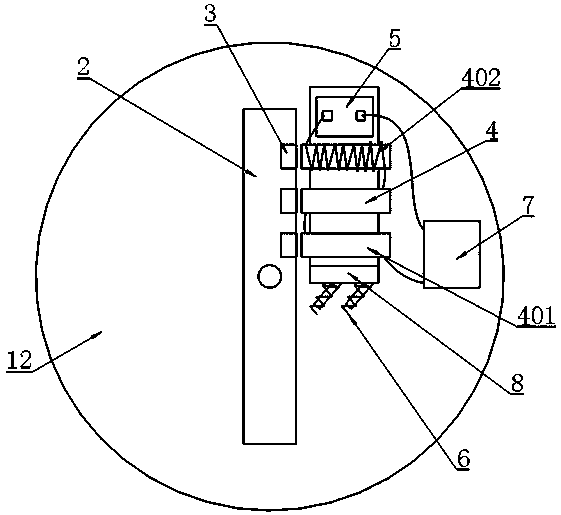

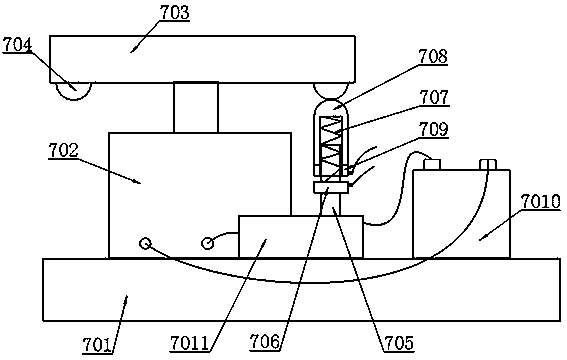

[0027] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a high-strength wood-plastic composite material includes 25-30 parts of high-density polyethylene, 60-70 parts of miscellaneous wood powder, 0.5-1.5 parts of calcium powder, 2-3 parts of maleic anhydride grafted PE, 2- 4 parts of polyethylene wax, and 5-7 parts of nano titanium dioxide crystal colloid.

[0028] In this embodiment, the nano-titanium dioxide crystal colloid is an anti-ultraviolet agent, which improves the sun-resistant durability of the wood-plastic composite material.

[0029] The preparation method of high-strength wood-plastic composite material includes the following steps in sequence:

[0030] S1. The raw materials are heated, stirred and mixed to obtain the material to be granulated;

[0031] S2, granulation;

[0032] S3, extrusion molding;

[0033] S4, high temperature deep embossing;

[0034] S5, surface grinding.

[0035] In the step S1, first add the miscellaneous woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com