A high-strength epoxy-barbed wire structure block reinforcement process

A technology of barbed wire and structures, applied in bridge reinforcement, construction, erection/assembly of bridges, etc., can solve the problems of low bonding performance between reinforcement materials and base materials, uneven distribution of fiber concrete, and high reinforcement technical requirements, and achieve a simple structure. , The structure is simple and clear, and the bonding performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

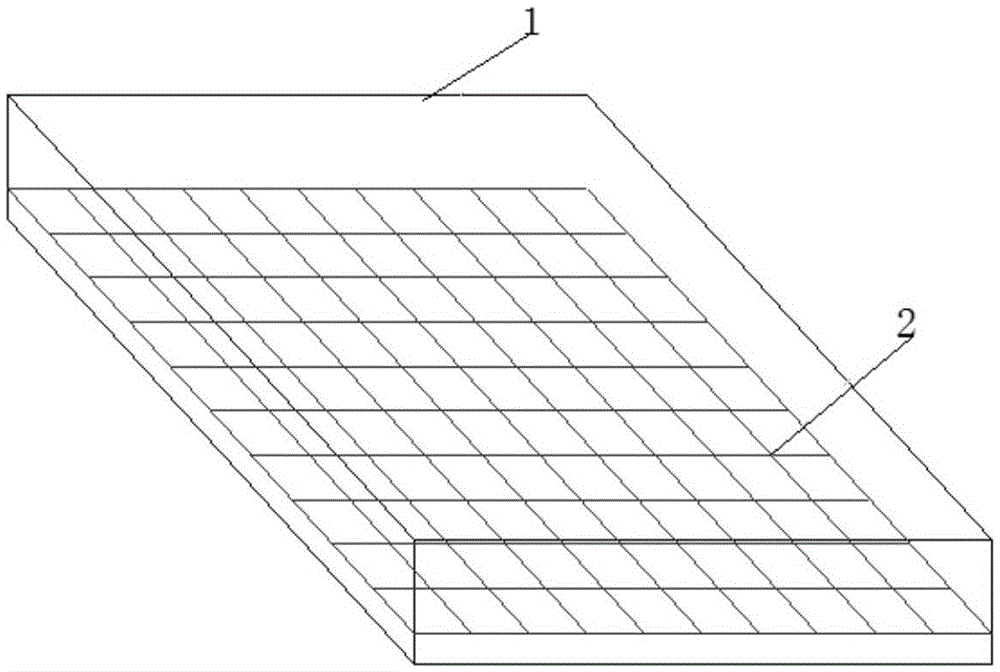

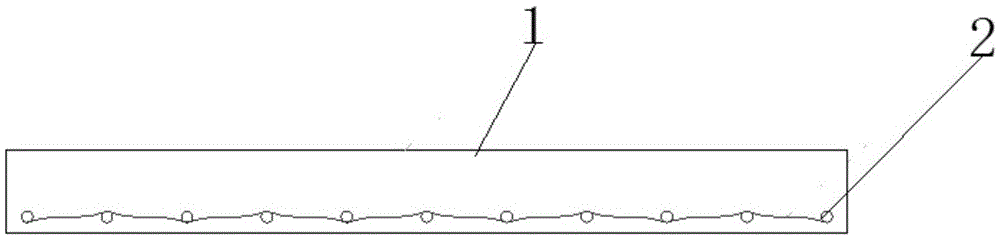

[0023] An epoxy resin grout and embossed woven barbed wire composite material and a preparation method thereof, wherein the epoxy resin grout is composed of three components, and the final viscosity and fluidity can be adjusted by adjusting the amount of component C; embossed The weaving method of woven barbed wire is rolling first and then weaving, and bidirectional wave-isolated bending. Now use this combined material to cast a 200×550×20mm four-point bending plate, such as figure 1 , figure 2 As shown, 1 in the figure is epoxy resin grouting material, and 2 is embossed braided barbed wire.

[0024] (1) Mixing ratio design: According to the actual situation of the project and the technical requirements of pouring, the mass mixing ratio of the three components of the epoxy resin grouting material is tested to be 3:1:25.4. 1%;

[0025] (2) Mold making: Lay thin and transparent plastic paper on the inside of the template of the board; according to the stress characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com