Wind tunnel test system for heat exchanger

A technology for testing systems and heat exchangers, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of small refrigerant temperature range, high safety requirements such as leakage prevention, and increased system costs, etc. Achieve the effect of wide test temperature range, low safety requirements, and reduced system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

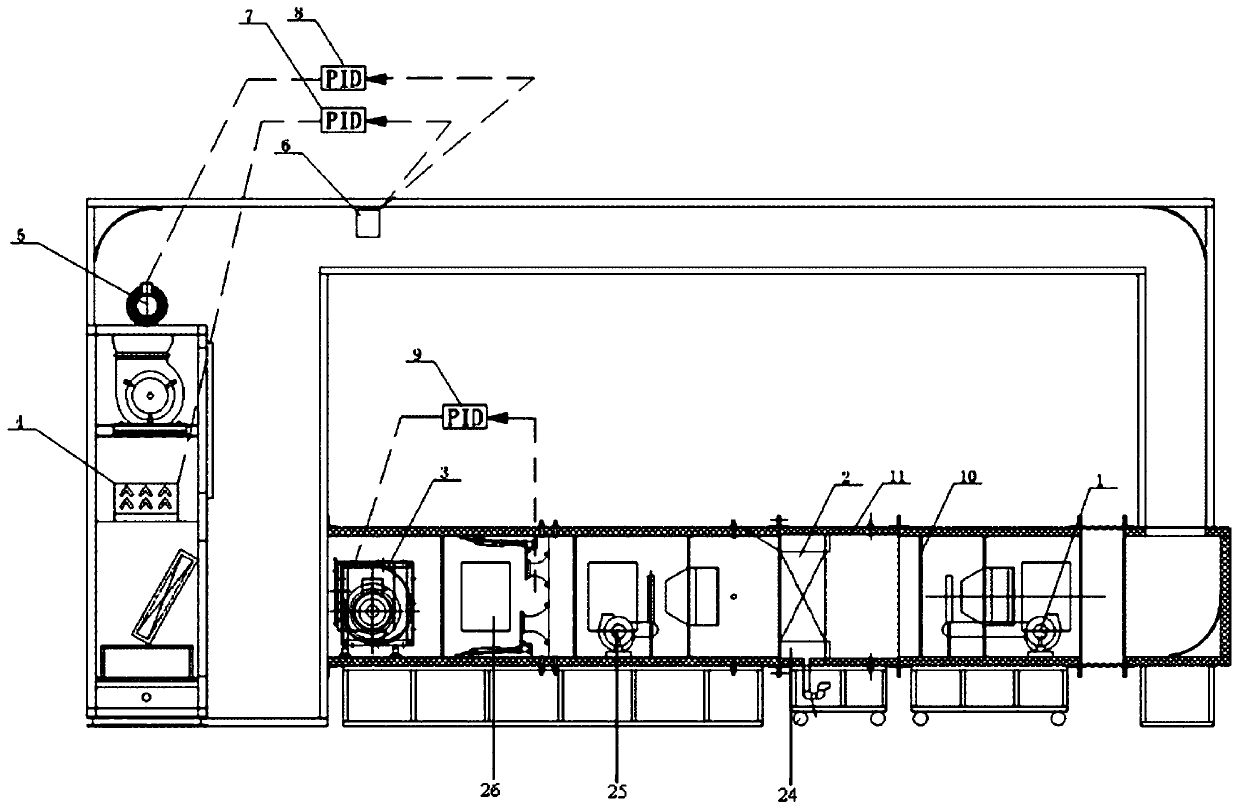

[0049] figure 1 and 2 Schematically shows a heat exchanger wind tunnel test system according to an embodiment of the present invention, including a wind-side circulation system and a water-side circulation system, both systems are provided with a tested heat exchanger 2 for installation The assembly section of the heat exchanger under test, so that the heat exchanger under test 2 can be connected to the two systems at the same time. Among them, the water side circulation system provides water circulation for the tested heat exchanger 2 to replace the refrigerant in the tested heat exchanger 2, and the air side circulation system provides the working conditions of the air side, and the heat exchange between water and air simulates the relationship between the refrigerant and the air. The heat exchange can realize the performance test of the heat exchanger. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com