Laser engraving device and engraving method for curved glass

A curved glass and laser engraving technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low processing efficiency, inability to process curved glass, complicated operation, etc., and achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

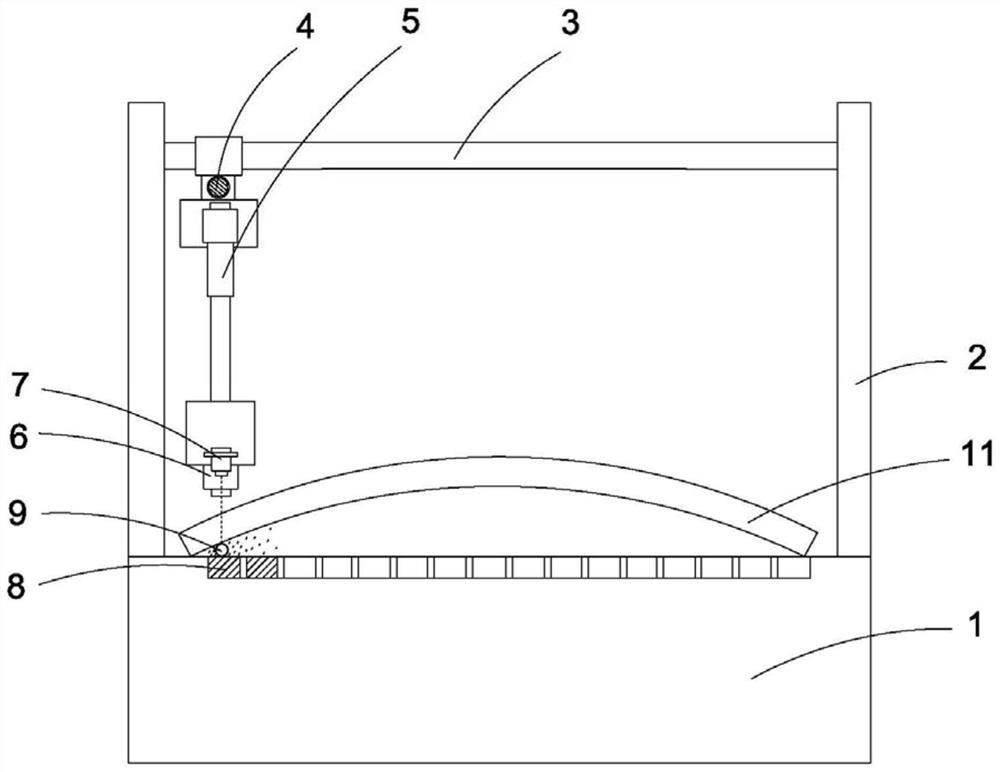

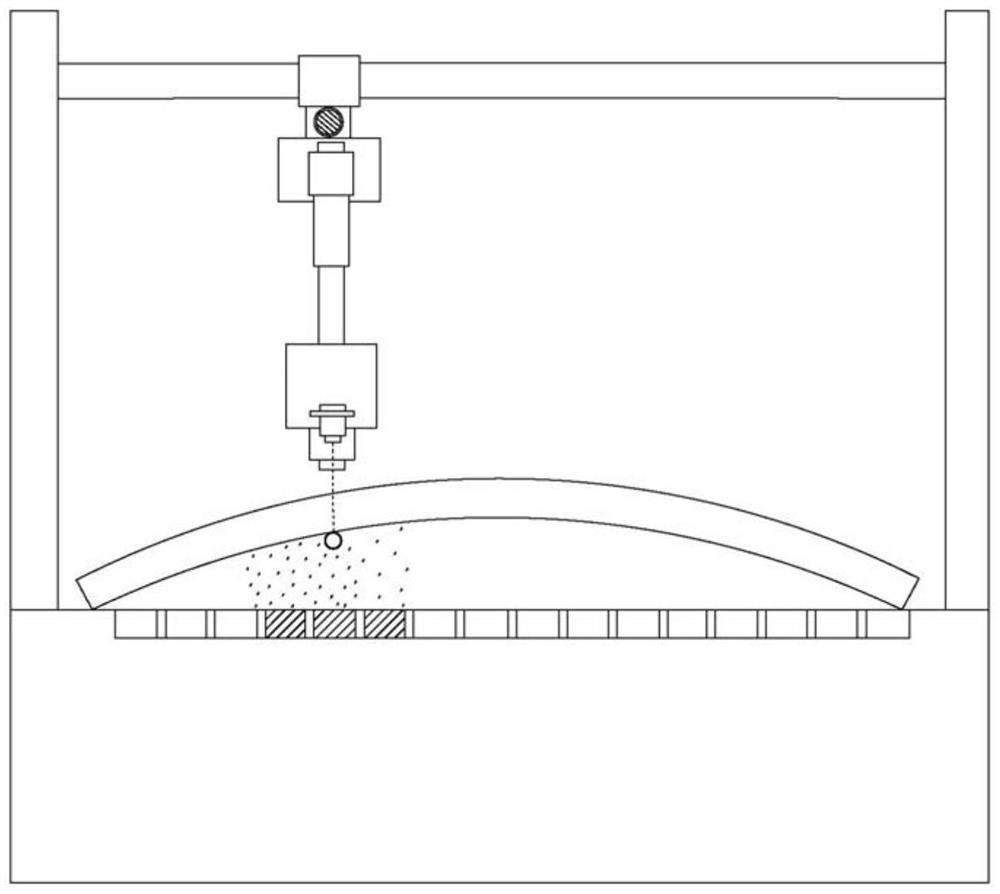

[0023] refer to Figure 1~4 Shown:

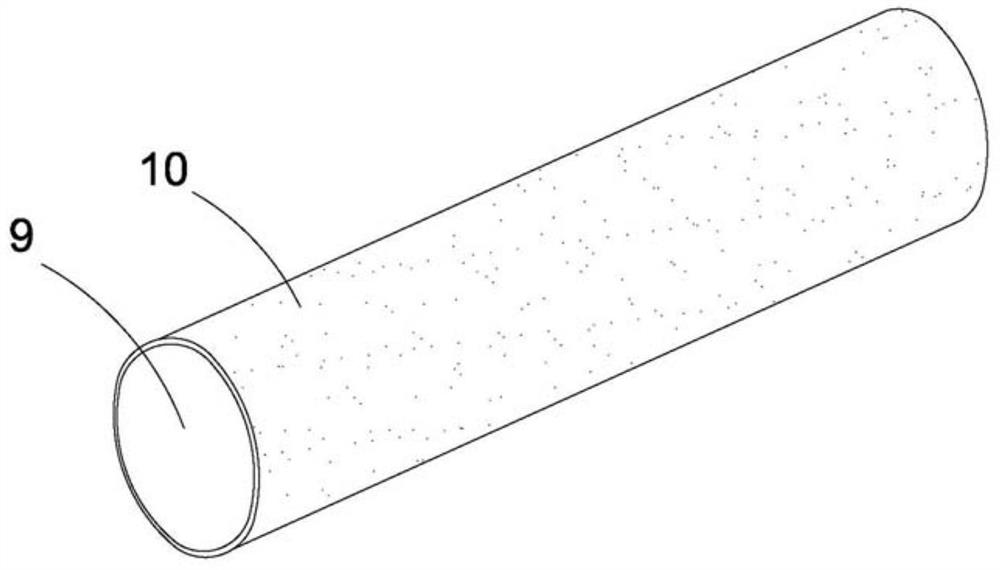

[0024] A laser engraving device for curved glass, comprising an operation table 1, columns 2 are fixed on both sides of the upper end of the operation table 1, an x-axis drive mechanism 3 is connected between the two columns 2, and the output end of the x-axis drive mechanism 3 is connected to a y The axis driving mechanism 4, the output end of the y-axis driving mechanism 4 is connected with the z-axis driving mechanism 5, the output end of the z-axis driving mechanism 5 is connected with the laser head 6 and the displacement sensor 7, and there are n intervals distributed in the operation table 1 Electromagnet 8, n is an integer greater than or equal to 5, a permanent magnet 9 with the same pole as the upper end of the electromagnet 8 is placed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com