Seat frame and adjusting structure of double-sided disc brake

A technology for adjusting structure and seat frame, which is applied in the direction of bicycle accessories, bicycle brakes, etc., can solve problems such as troubles, inability to adapt to vehicles with larger frames, troubles in assembly, etc., achieve simple spacing adjustment, solve the phenomenon of disc rubbing, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with implementation.

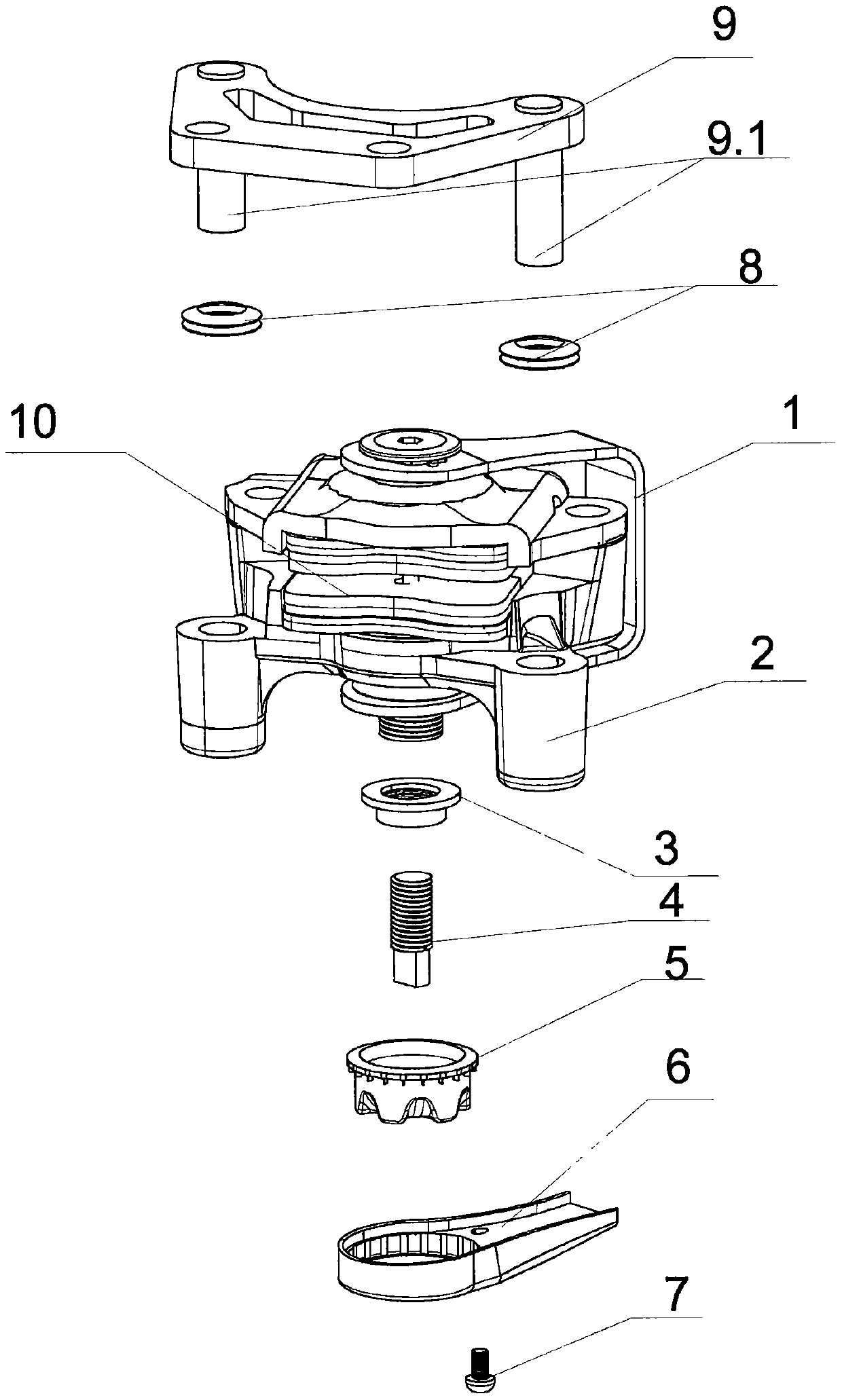

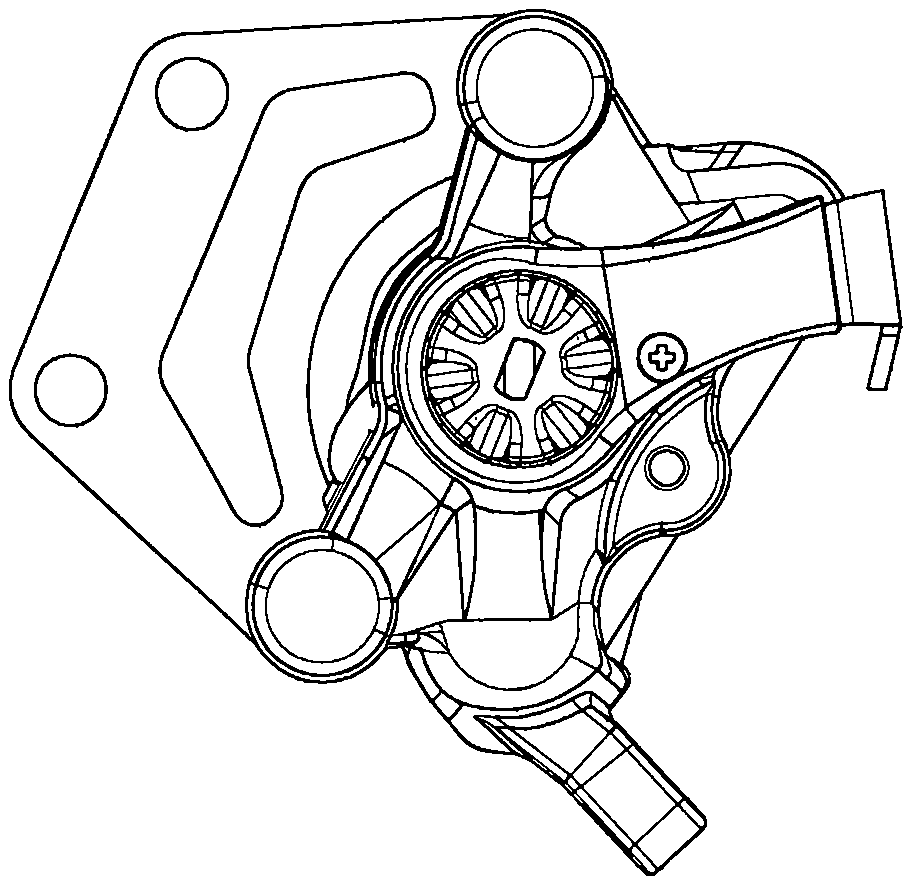

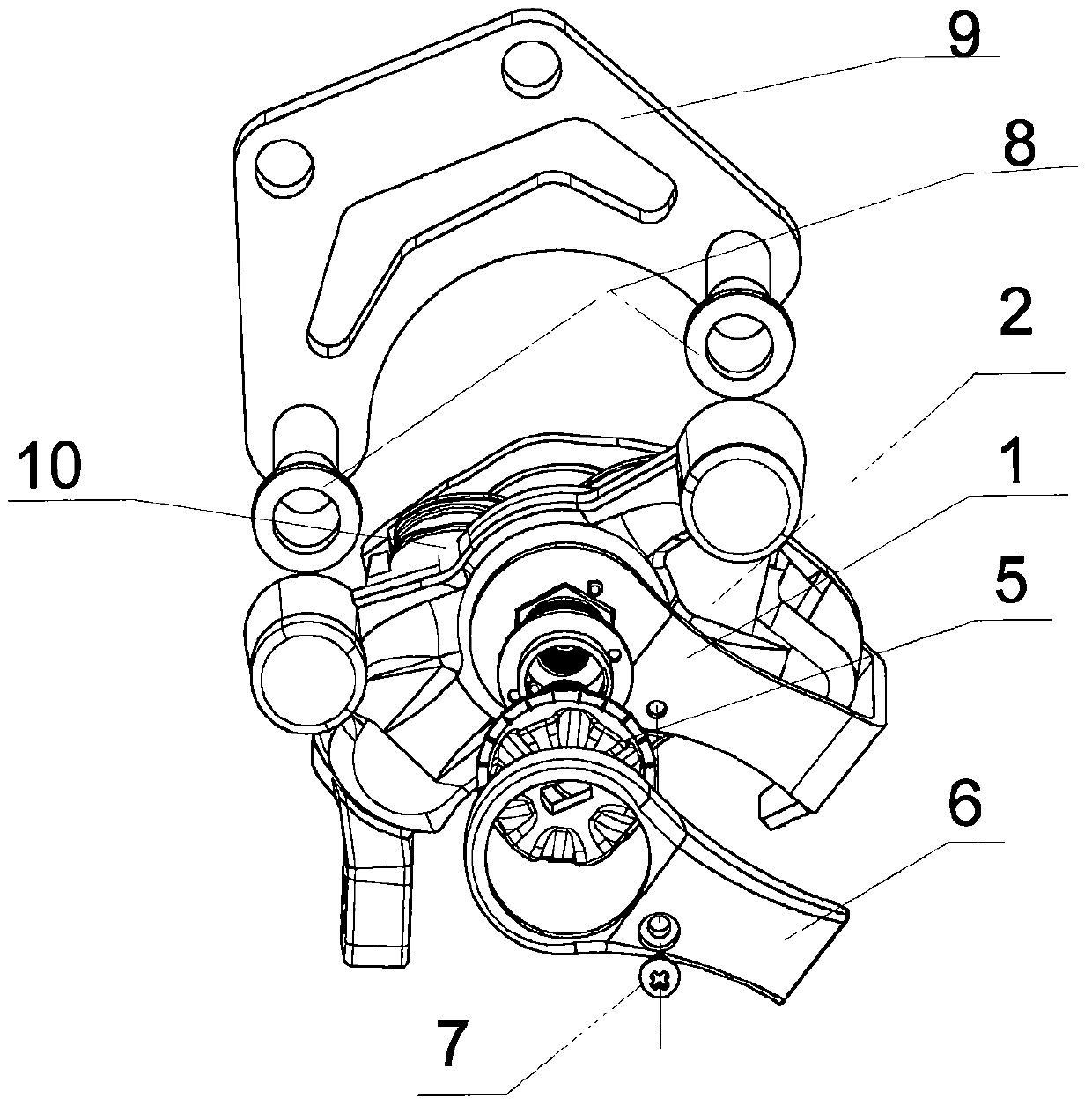

[0014] figure 1 , figure 2 and image 3 Shown in is the three-dimensional exploded view and the front view of the seat frame and the adjustment structure of the double-sided disc brake of the present invention. Sliding hole 2.3, the steel column 9.1 of seat frame 9 is inserted in sliding hole 2.3, seat frame 9 is made up of steel plate and equal-section steel column 9.1 perpendicular to steel plate, between steel column 9.1 and sliding hole 2.3 on the tong shell 2 is Sliding fit in a small gap, the steel column 9.1 is covered with a dust retaining ring 8. When the disc brake is working, the small gap sliding fit can well adjust the position of the caliper body 10 to ensure that the disc is centered and there will be no disc rubbing phenomenon. The traditional method of adding rubber damping rings and springs is easy to cause disc rubbing, especially when the frame, front for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com