Device and method configured to control rotation of an object on a carrier

An object, controller technology, applied in the field of rotating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

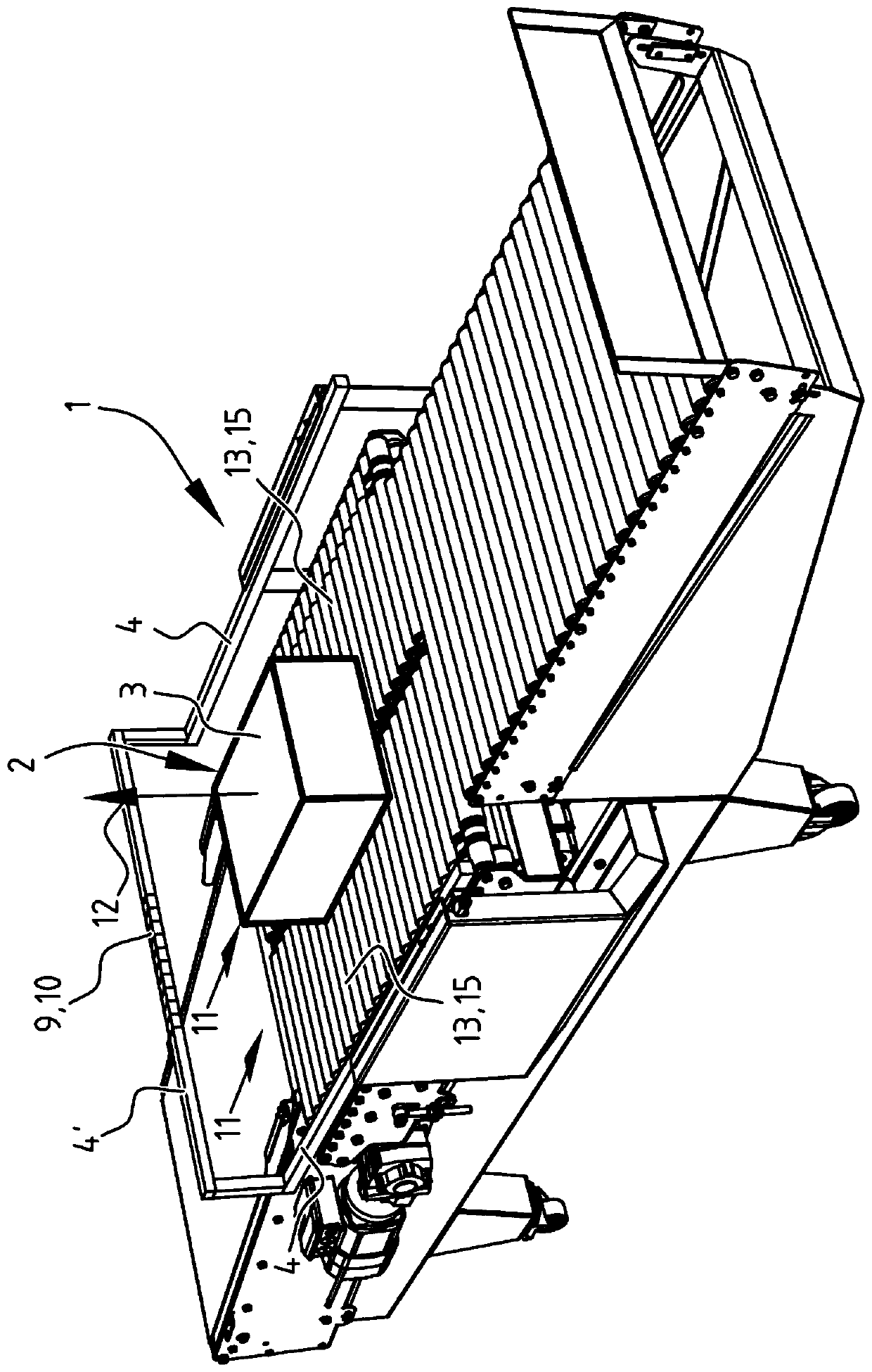

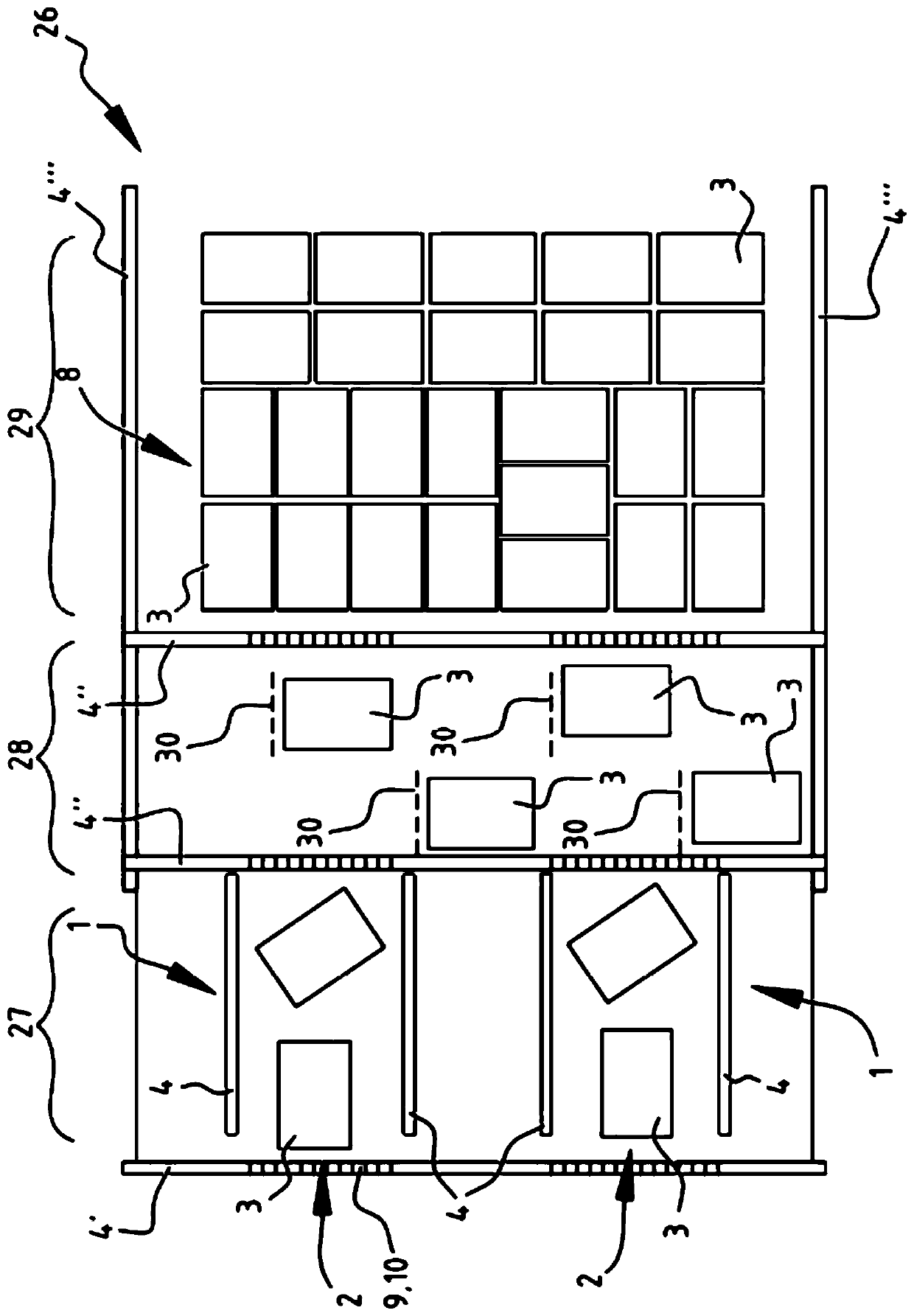

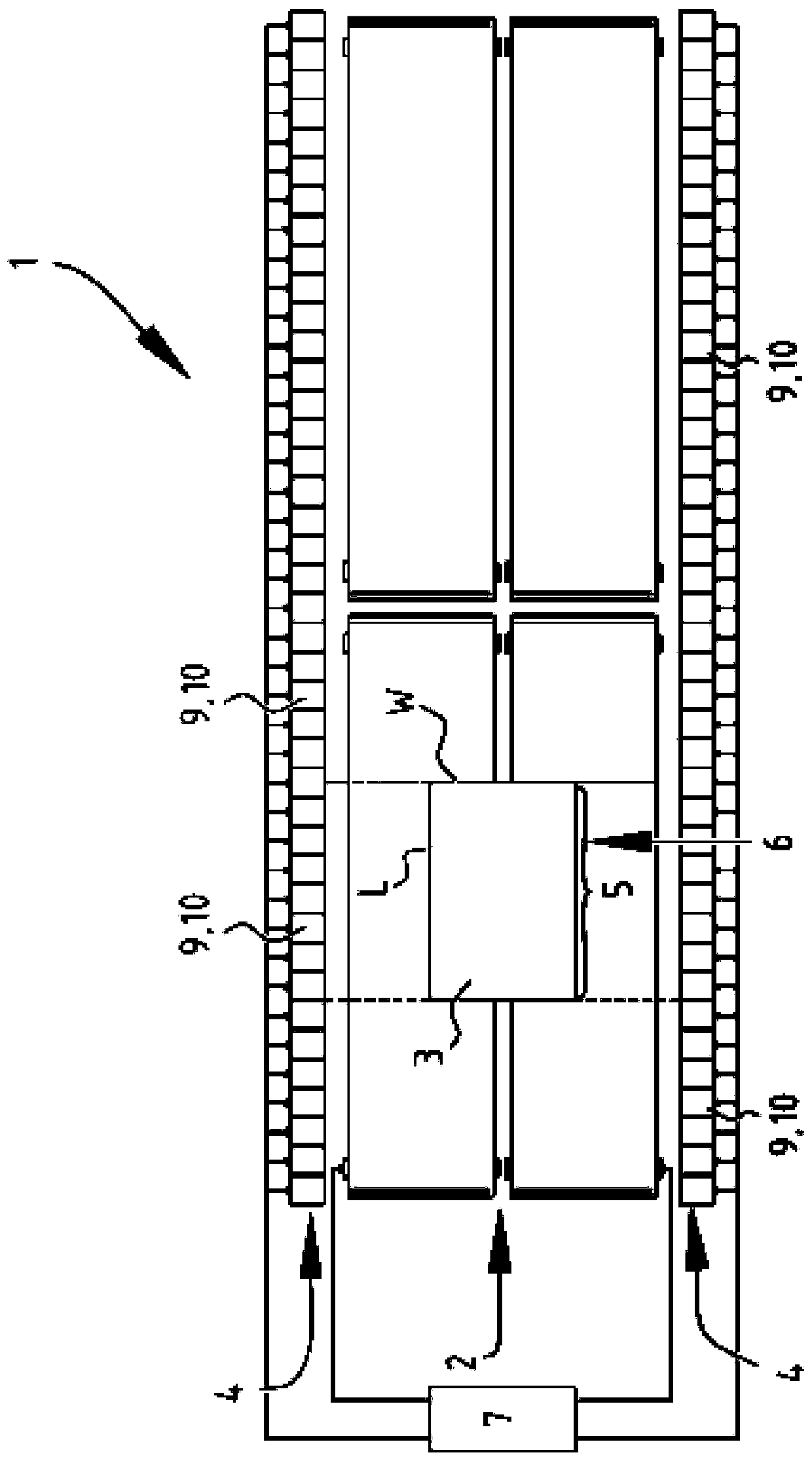

[0035] figure 1 and figure 2 The device 1 shown in includes: a carrying mechanism 2 to successively carry objects 3 ; a scale 4 configured to measure a dimension 5 of the object 3 relative to at least one direction 6 . The apparatus 1 further comprises a controller 7 configured to determine a change in the size 5 of the object 3 and configured to control the rotation of the object 3 based on the determined change in the size 5 of the object 3 so that the object 3 is aligned in the in the desired orientation.

[0036] The gauge 4 is configured to measure the outer dimensions of the side surfaces of the object 3 , and the controller 7 is configured to align the side surfaces of the object 3 substantially in the transport direction of the object 3 . Based on the outer dimensions of the side surfaces of the object 3, the controller 7 can precisely align the object 3 in a desired orientation.

[0037] The carrying mechanism 2 is configured to successively rotate the object 3 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com