Sealed high-voltage direct current relay

A high-voltage direct current, sealed technology, applied in the direction of relays, electromagnetic relays, high-voltage air circuit breakers, etc., can solve the problems of the winding space of the magnetic circuit part becoming smaller, affecting the performance of the magnetic circuit, affecting the insulation distance, etc., to achieve the winding space Maximize and improve the magnetic circuit performance and avoid the effect of insulation performance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

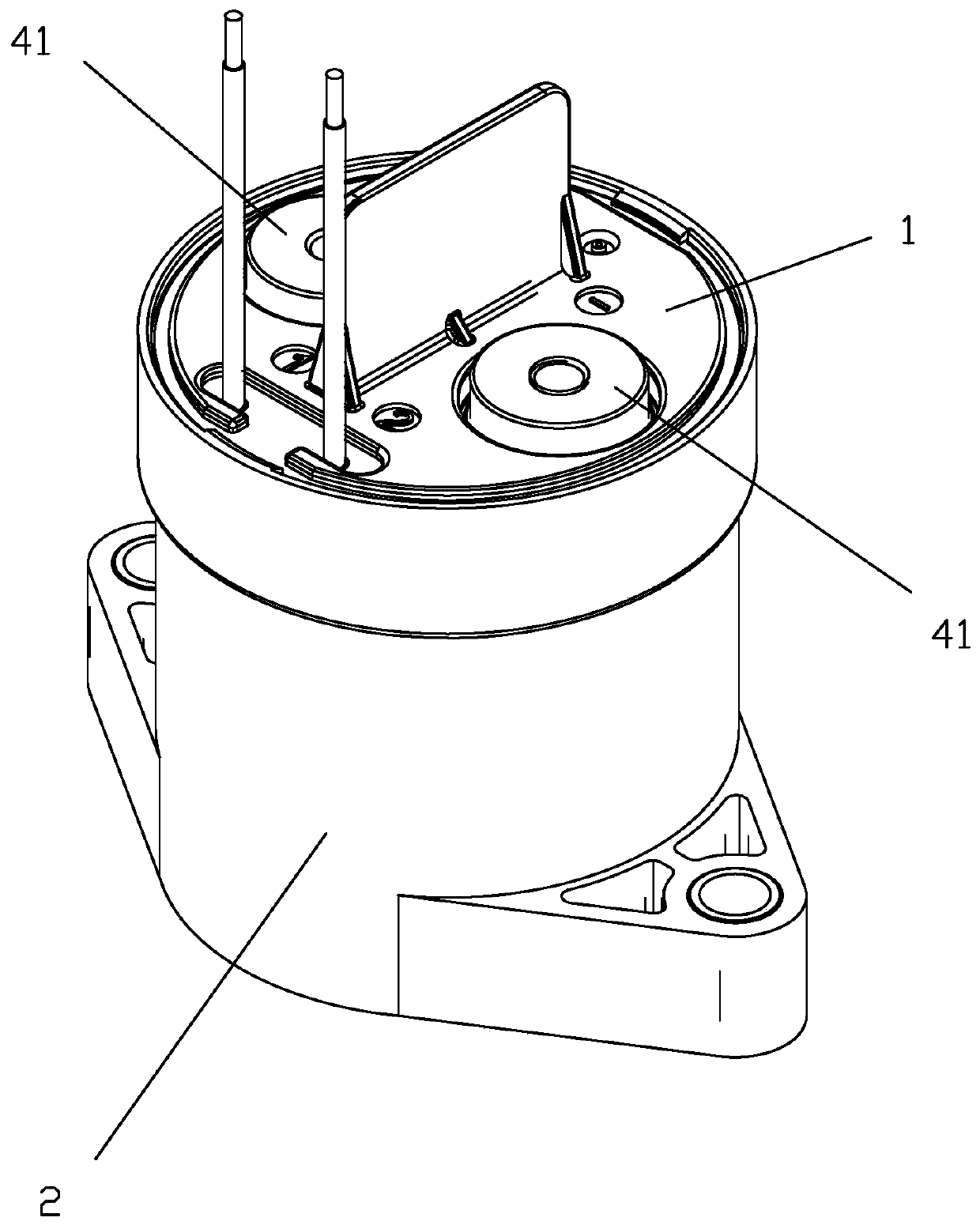

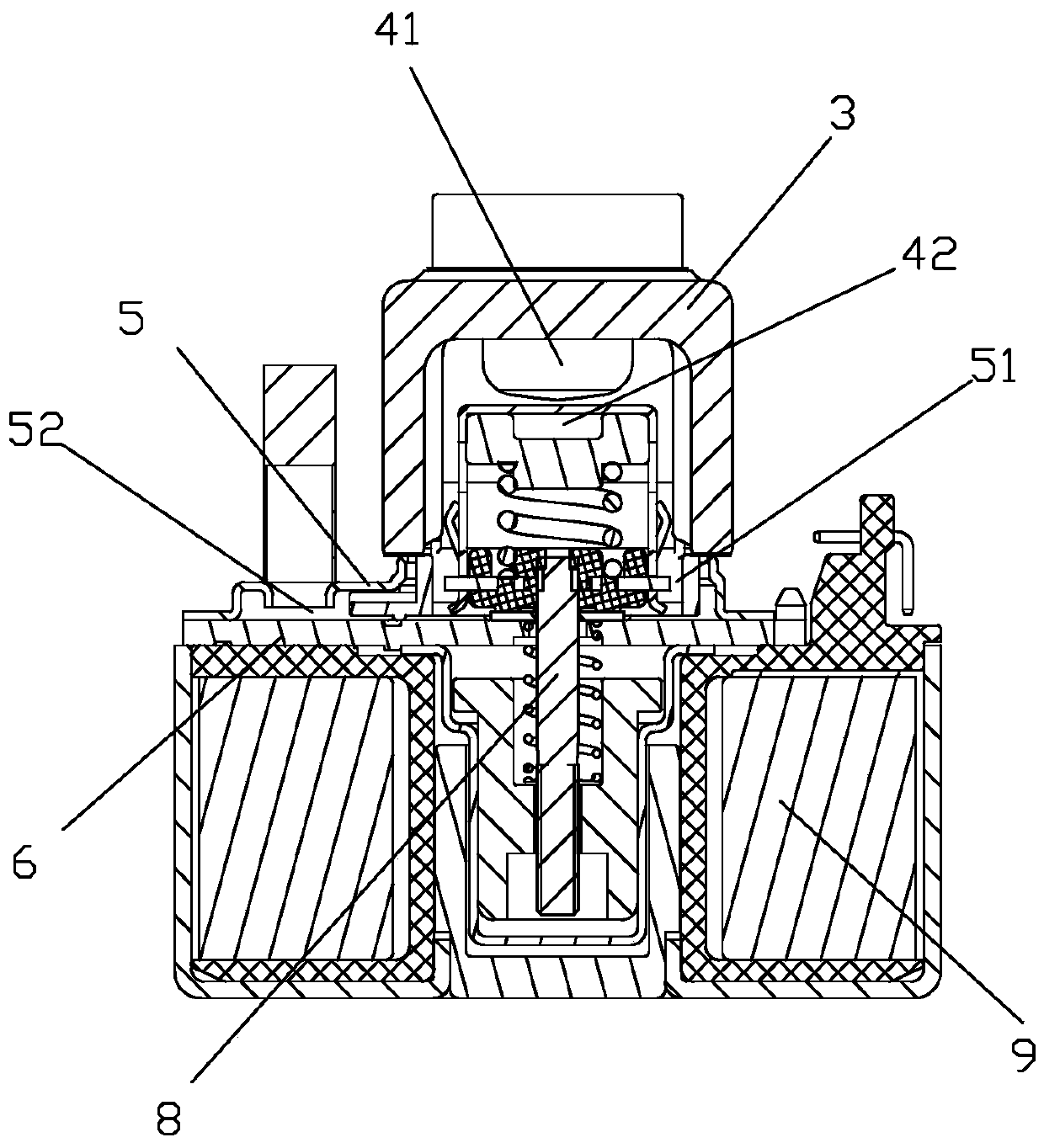

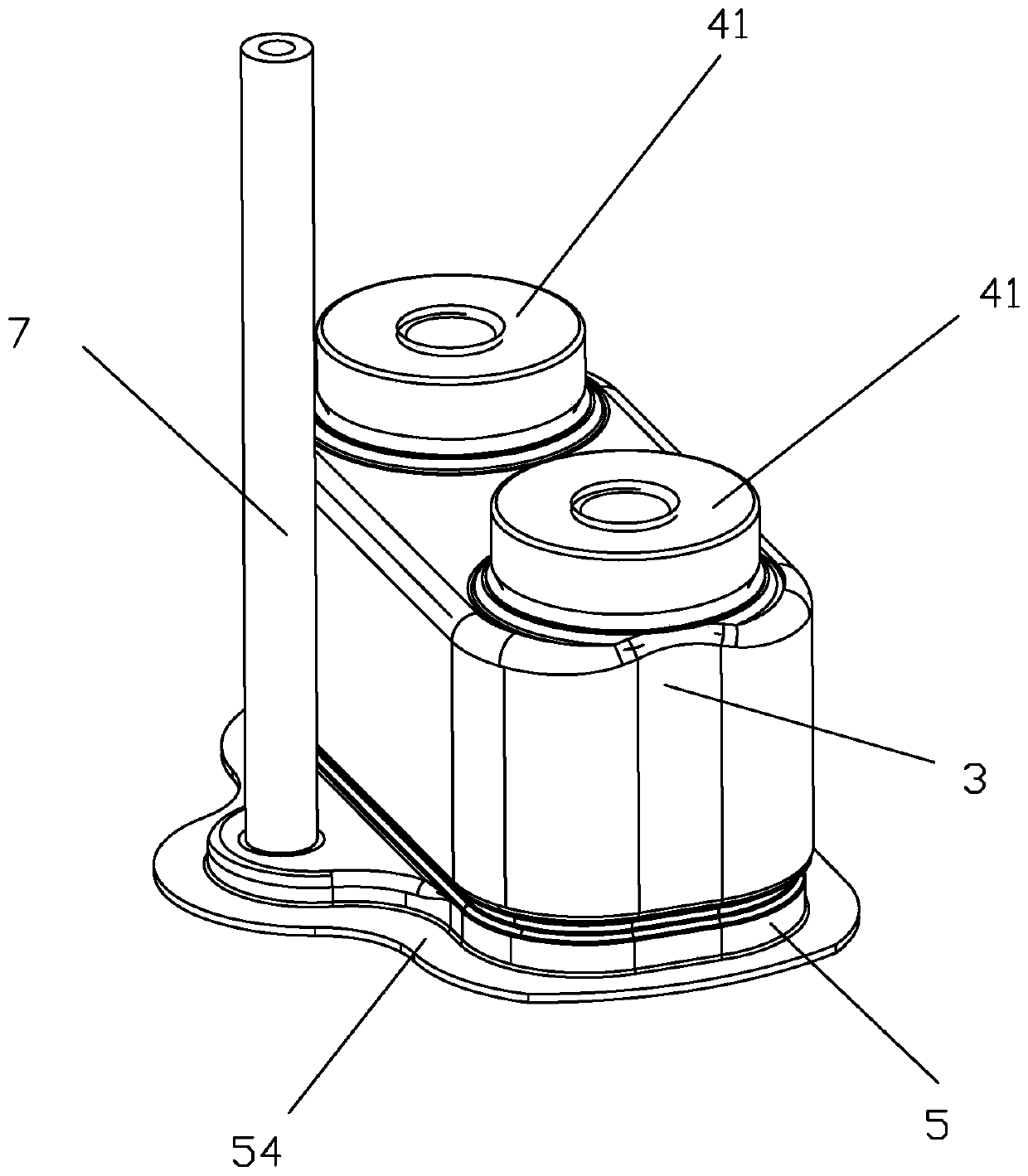

[0028] See Figure 1 to Figure 14 As shown, a sealed high-voltage DC relay of the present invention includes a cover plate 1, a base 2, a ceramic cover 3, two load lead-out ends 41, a movable spring 42, a metal frame sheet 5, a yoke plate 6, and copper The exhaust pipe 7, the pushing part 8, and the coil 9 are components; among them, the ceramic cover 3 is roughly rectangular, and the yoke plate 6 is roughly circular; the two load lead-out ends 41 (ie, static contact lead-out ends) are respectively Installed on the top wall of the ceramic cover 3, the bottom ends of the two load lead-out ends 41 respectively extend into the cavity of the ceramic cover and cooperate with the movable spring 42. The movable spring 42 is installed at one end of the pushing part 8, and the pushing part 8 The other end is matched with the coil; the peripheral dimension of the top end of the metal frame piece 5 is matched with the peripheral dimension of the bottom end of the ceramic cover 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com