IPM packaging method and bonding method in IPM packaging

A bonding and bonding process technology, applied in the field of bonding, can solve problems such as low yield, improve yield and performance, avoid poor insulation performance, and avoid poor voltage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

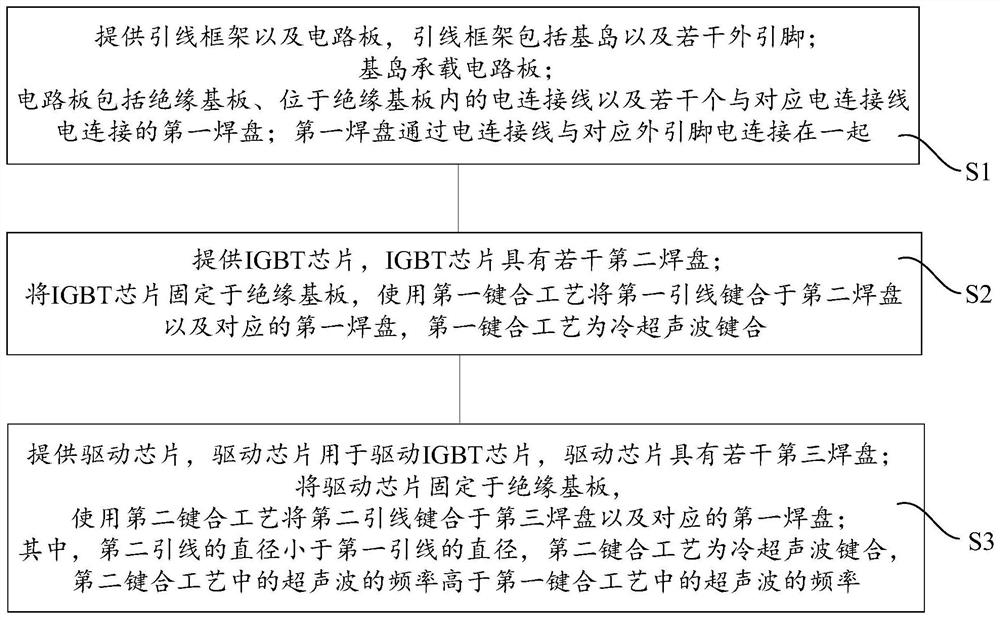

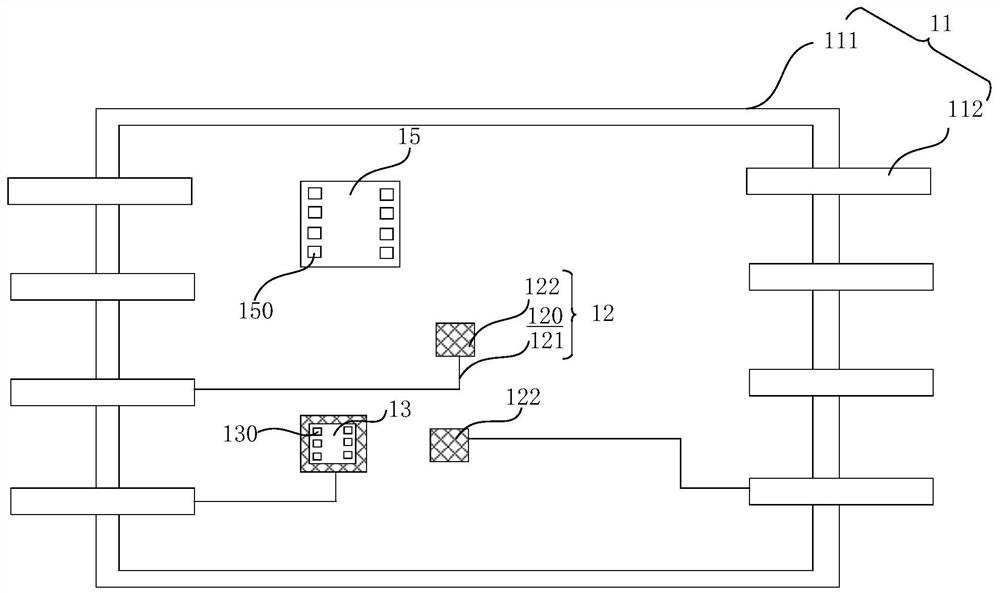

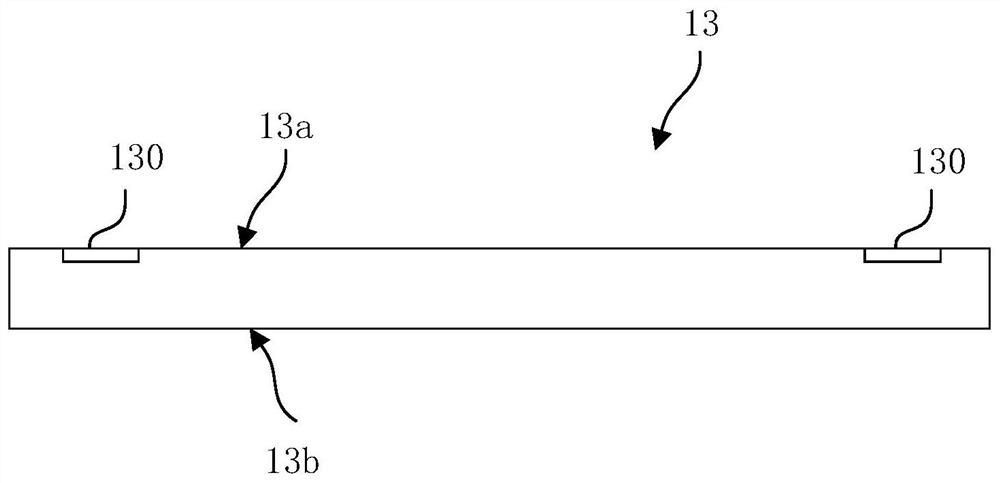

[0043] The inventor researched and analyzed the IPM packaging process, and found that one of the reasons for the low IPM yield rate is that the driver chip requires more and thinner leads, so gold wires, copper wires, etc. are generally used between the driver chip and the circuit board for thermal ultrasonic wire bonding; thermal ultrasonic bonding requires high temperature heating in the equipment track, high temperature will cause the insulating substrate carrying the IGBT chip to separate from the base island, tearing, on the one hand, the tearing of the insulating substrate will cause the bottom of the IGBT chip The breakdown between the electrode and the base island results in poor breakdown resistance of the IPM, that is, poor voltage resistance; on the other hand, the IGBT chip is separated from the base island, which affects the heat dissipation performance.

[0044] In order to make the above objects, features and advantages of the present invention more comprehensibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com