An automatic laying system of insulating sand for subway platform doors

A technology of automatic laying and platform doors, which is applied in the direction of construction and building construction, can solve the problems of electrification of the door body, high labor intensity, etc., and achieve the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

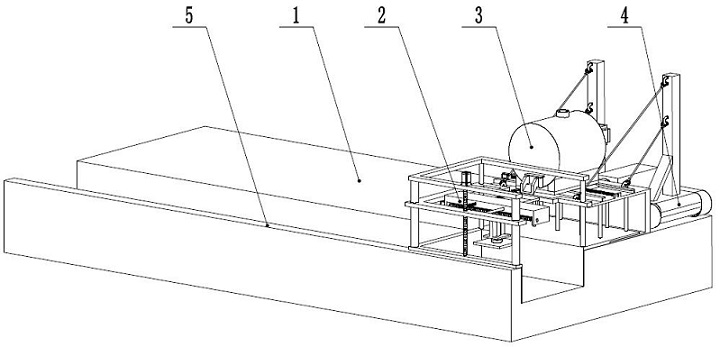

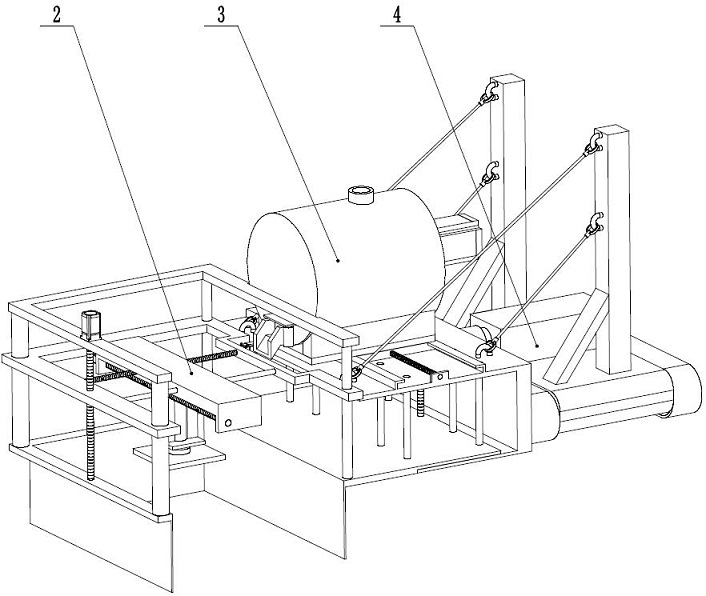

[0016] Example: such as Figure 1-7 As shown, this embodiment provides an automatic laying system of insulating sand for subway platform doors, including: a pressing device 2 installed on the mobile support part 4 for laying and pressing the insulating sand; a stirring device 3 installed on the mobile supporting device 4 is used to mix yellow sand and glue to form insulating sand; the mobile supporting device 4 is placed on the platform 1 and can be moved.

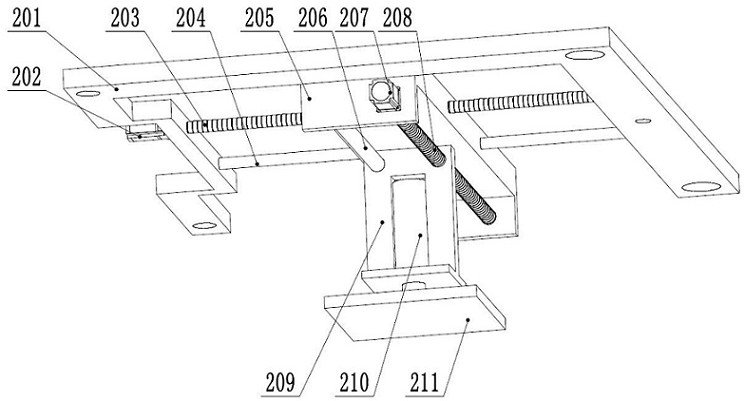

[0017] In the optional scheme of this embodiment, such as Figure 1-3 As shown, the lifting frame 201 in the pressing device 2 is installed on the support column 404 in a slidable manner, the lifting frame 201 and the lifting screw rod 403 adopt thread transmission, the left and right motors 202 are installed on the lifting frame 201 in a fixed manner, and the left and right screw rods 203 one ends are fixedly installed on the motor shaft of the left and right motors 202, the left and right screw mandrels 203 other ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com