Ink tank unit, printer

A technology of printers and ink tanks, applied in printing and other fields, can solve problems such as troublesome opening and closing operations and difficult for users to know

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

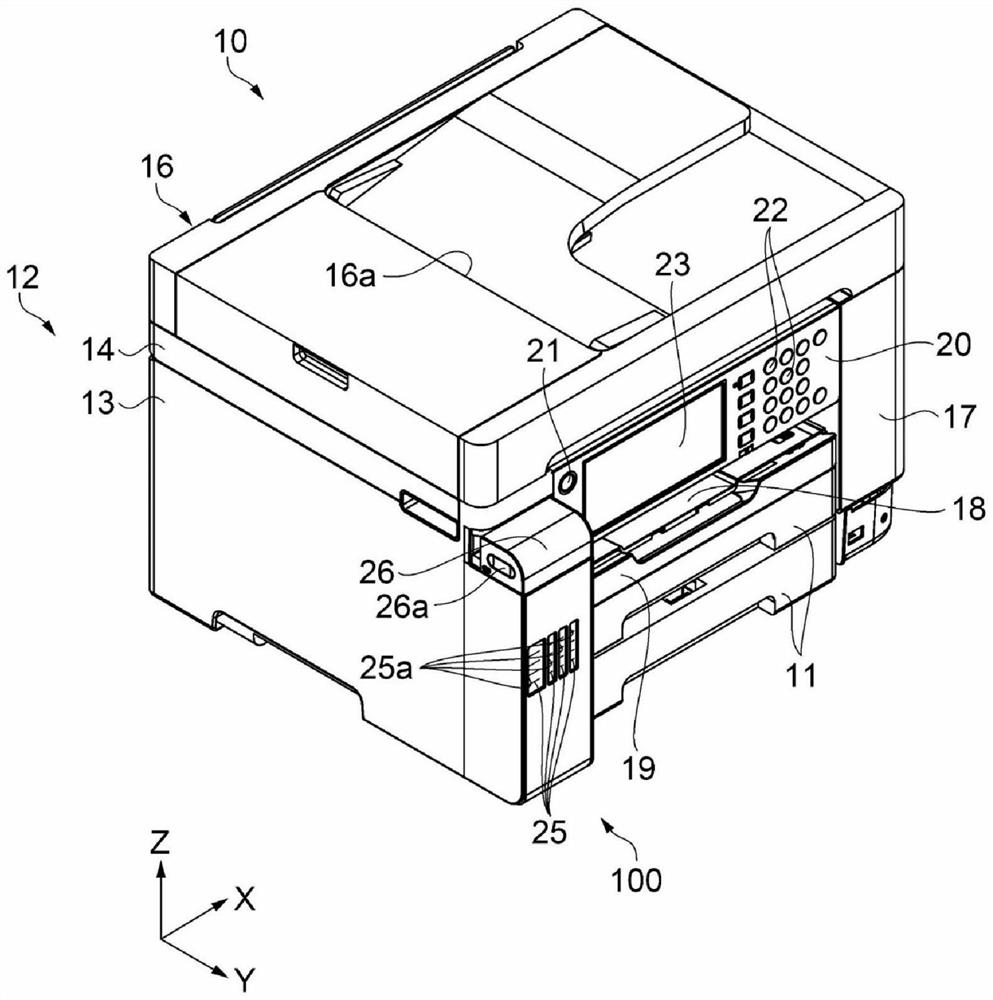

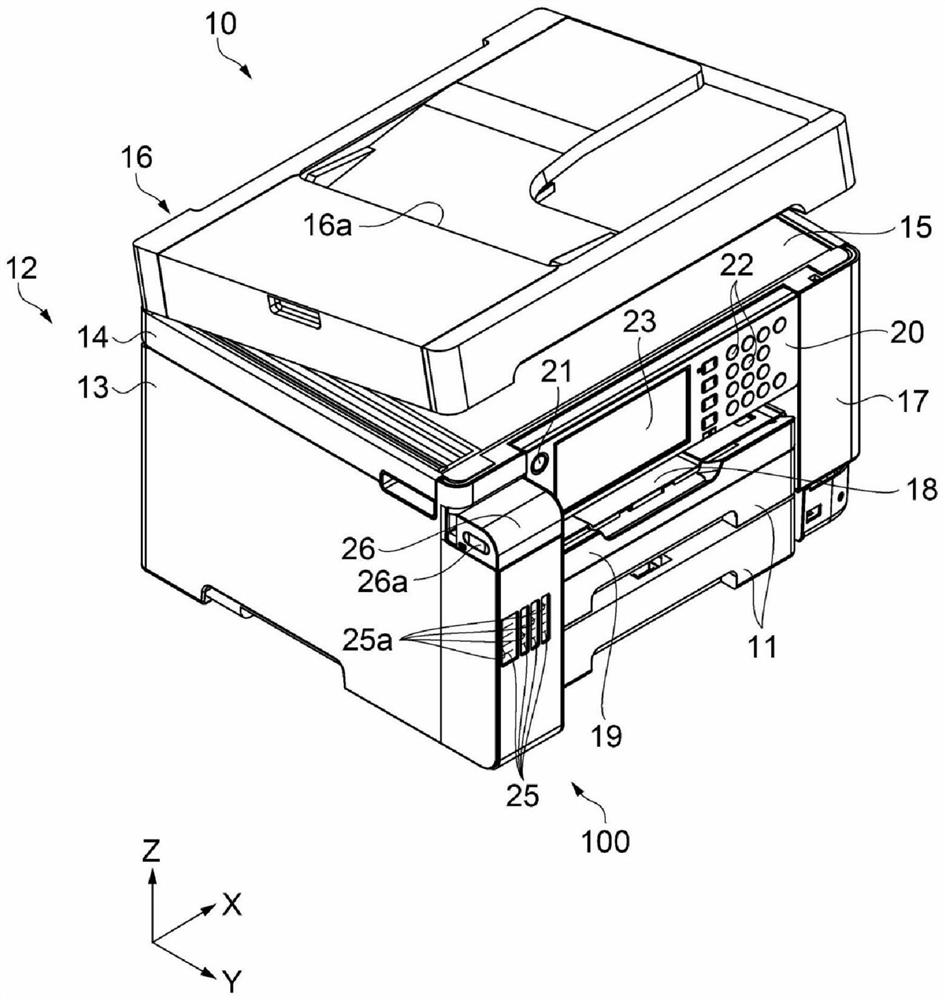

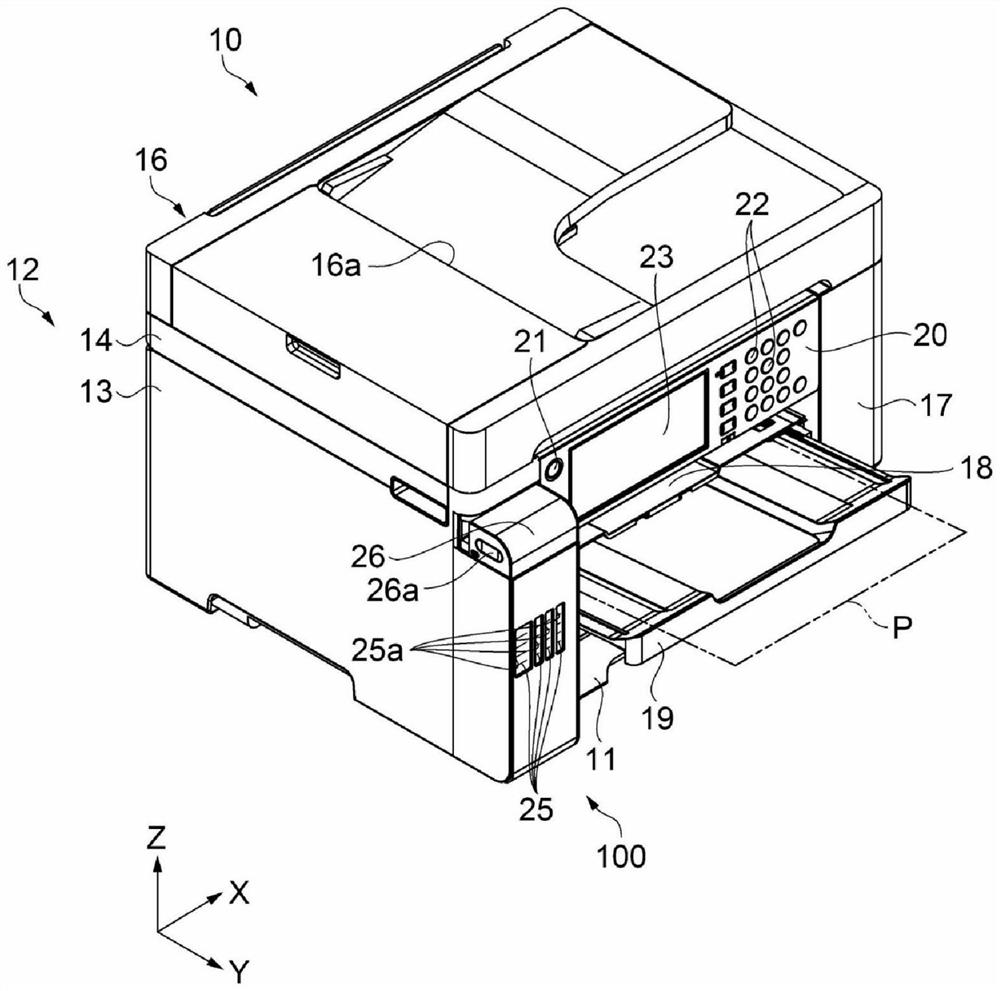

[0031] First, the configuration of the printer 10 will be described.

[0032] Figure 1 to Figure 4 It is a perspective view showing the structure of the printer 10 . in particular, figure 1 represents the appearance of the printer 10, figure 2 Indicates the open state of the cover portion 16 serving as the cover unit in the printer 10, image 3 represents the discharge state of the medium P in the printer 10, Figure 4 The open state of the tank cover 26 in the printer 10 is shown.

[0033] like figure 1 As shown, the printer 10 is an ink jet printer that ejects ink, which is an example of a liquid, on a medium P such as paper to perform recording.

[0034] In addition, in figure 1 , the X-axis, Y-axis and Z-axis which are orthogonal to each other are drawn. figure 1 The X-axis, Y-axis, and Z-axis of the graph correspond to the X-axis, Y-axis, and Z-axis of other graphs. The graphs shown hereafter also have an X-axis, a Y-axis, and a Z-axis added as necessary. Th...

no. 2 approach

[0090] Next, the second embodiment will be described. In the present embodiment, a configuration different from that of the first embodiment, that is, the configuration of the ink tank unit 100A will be described. In addition, since the structure other than the ink tank unit 100A is the same as the structure of 1st Embodiment, description is abbreviate|omitted.

[0091] Figure 14 It is a cross-sectional view showing the structure of the ink tank unit 100A according to the present embodiment.

[0092] Here, in the above-mentioned first embodiment, as Figure 5 As shown, the first rotating shaft 37 and the second rotating shaft 38 are arranged on the +Y direction side rather than the ink inlet opening 49a, and the tank cover 26 and the cover member 50 are rotated to the +Y direction side to allow the ink inlet opening 49a open.

[0093] However, in the ink tank unit 100A of the present embodiment, as Figure 14 As shown, the second rotating shaft 38 for rotating the tank c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com