A fabric storage device

A fabric and stacking technology, applied in the field of fabric storage, can solve the problems of fabric wrinkles, mildew, fading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

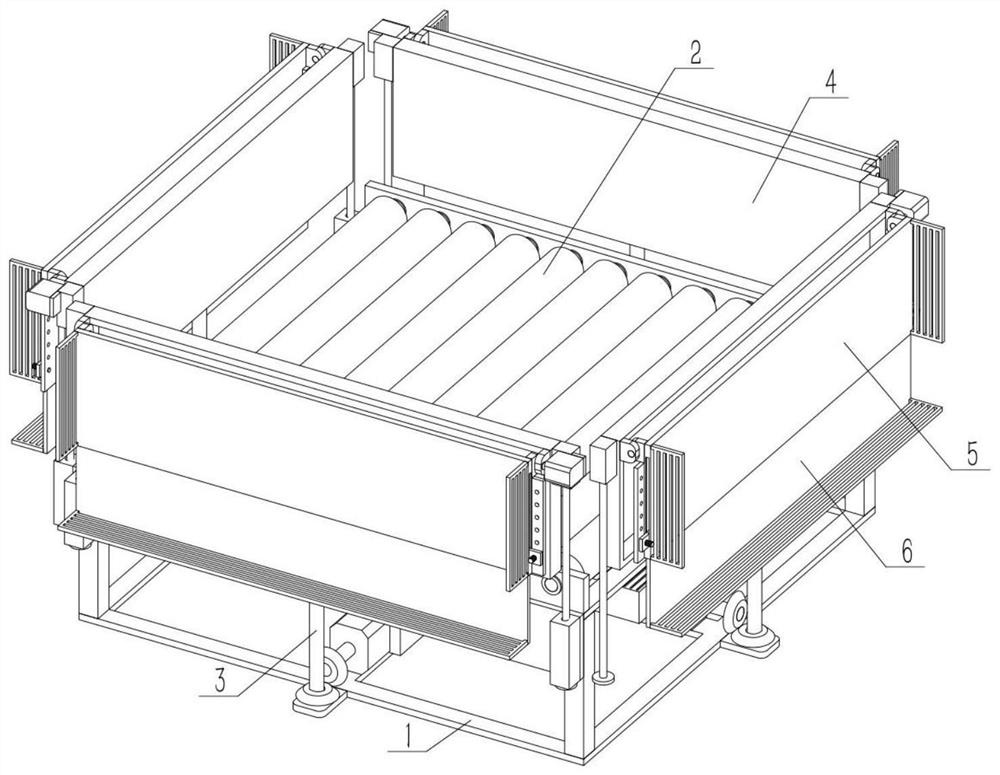

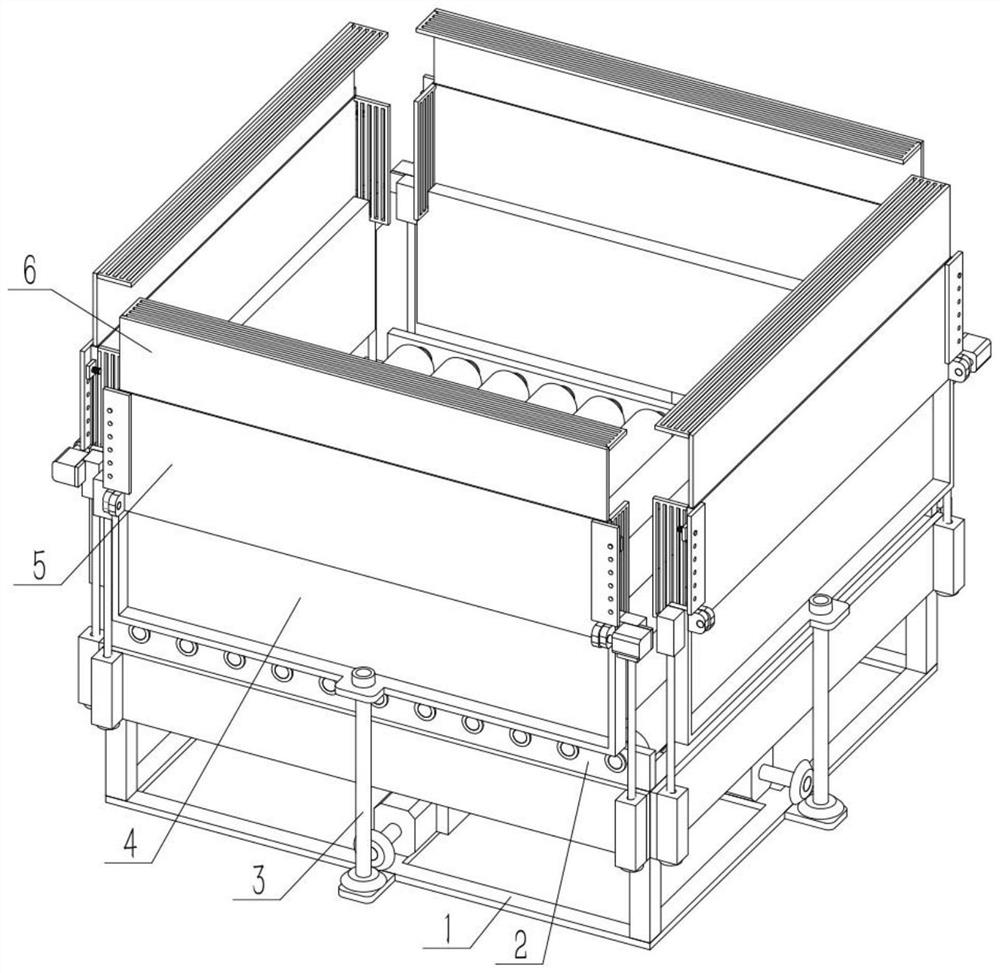

[0031] Such as Figure 1-10 As shown, a fabric stacking device includes a bottom frame 1, a stacking frame 2, a lifting screw 3, a lifting coaming 4, a loading and unloading coaming 5 and an expansion coaming III 6, and the upper end of the bottom frame 1 is fixedly connected to the stacking Frame 2, four lifting screw 3 are provided with, and four lifting screw 3 are respectively rotated and connected around the bottom frame 1, four lifting coamings 4 are provided with, and four lifting coamings 4 are respectively connected with stacking frame 2. Sliding connection around, four lifting coamings 4 are threadedly connected with four lifting screw 3 respectively, there are four loading and unloading coamings 5, four loading and unloading coamings 5 are respectively connected with four lifting coamings 4, expansion coaming III 6 There are four, and the four expansion coamings III 6 are respectively connected with the four loading and unloading coamings 5 . Roller 203 can mak...

specific Embodiment approach 2

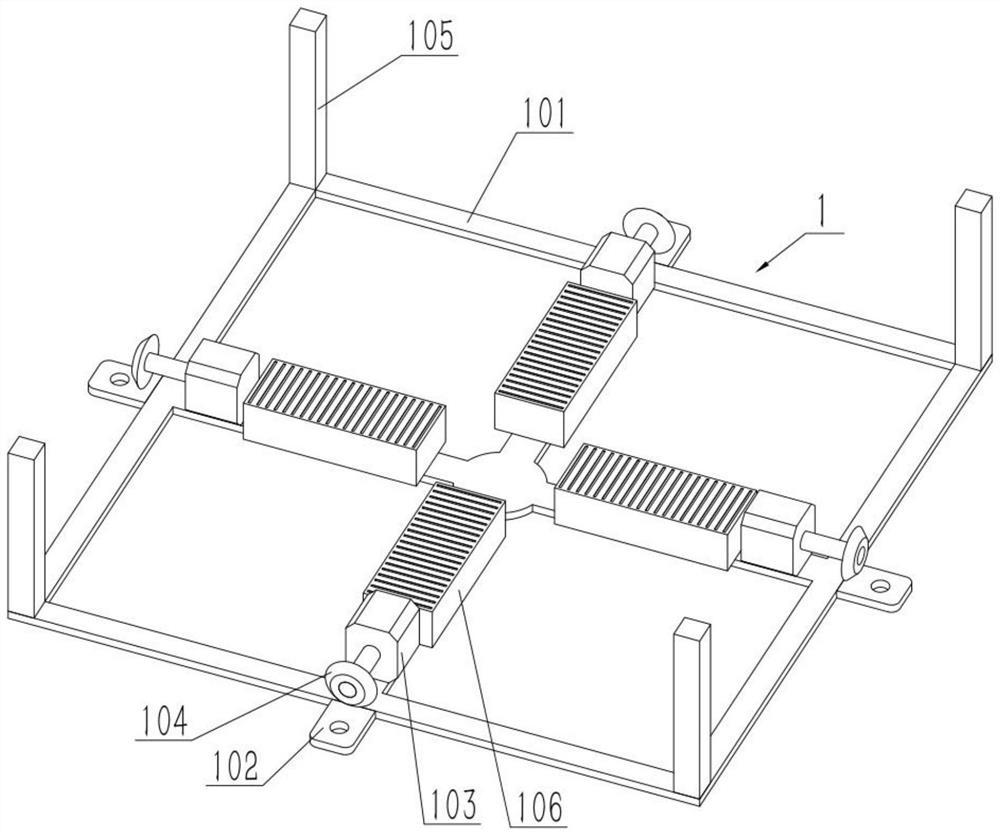

[0033] Such as Figure 1-10 As shown, the bottom frame 1 includes a bottom frame body 101, a bottom connection portion 102, a motor I 103, a helical gear I 104, and a pole 105, and the middle parts around the bottom frame body 101 are respectively fixed with a bottom connection portion 102, and the bottom frame A motor I103 is respectively fixed on the four sides of the body 101, a helical gear I104 is respectively fixed on the output shafts of the four motors I103, and a strut 105 is respectively fixed on the four corners of the bottom frame body 101. One of the motors I103 can be started, the output shaft of the motor I103 drives the helical gear I104, and the helical gear I104 drives the helical gear II302 engaged with it to rotate.

specific Embodiment approach 3

[0035] Such as Figure 1-10 As shown, the bottom frame 1 further includes air blowers 106 , and four air blowers 106 are evenly fixed in the circumferential direction of the bottom frame body 101 . Start the hot air blower 106 to convey hot air upwards from the bottom of the fabric rolls. Combined with the stacking method, there is a gap between the rolls, and the hot air can pass through each layer of fabric rolls, which helps the fabric rolls to dry and prevent moisture in humid weather. , can change the quantity of starting hot air blower 106 according to the situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com