Air-inflation rapid demolding device and mold

A demoulding device and mold technology, applied in the direction of molds, unloading devices, manufacturing tools, etc., can solve the problem of not being able to demould multiple samples at one time, and achieve overcoming easy cracking and damage, improving success rate and demoulding efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

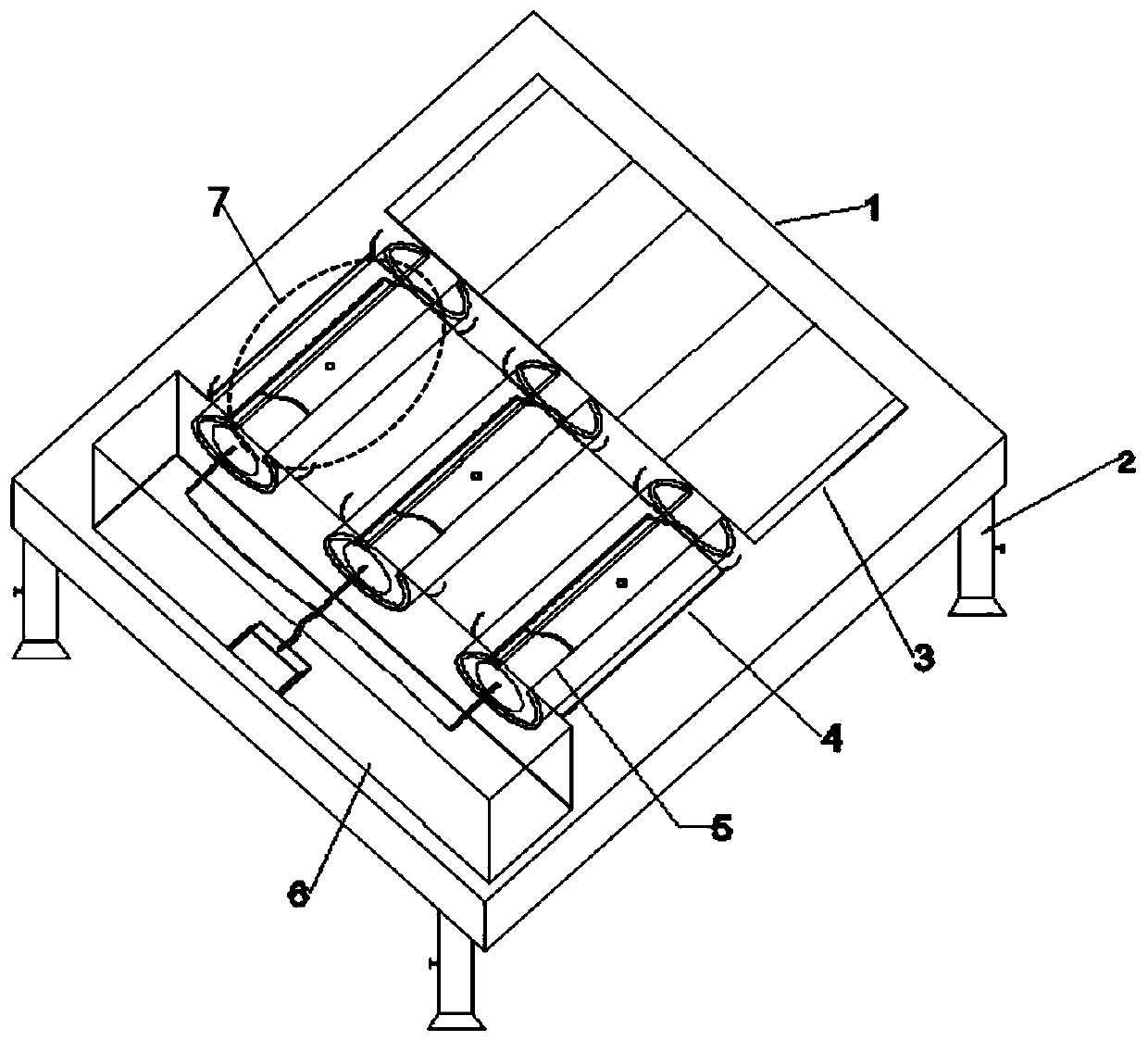

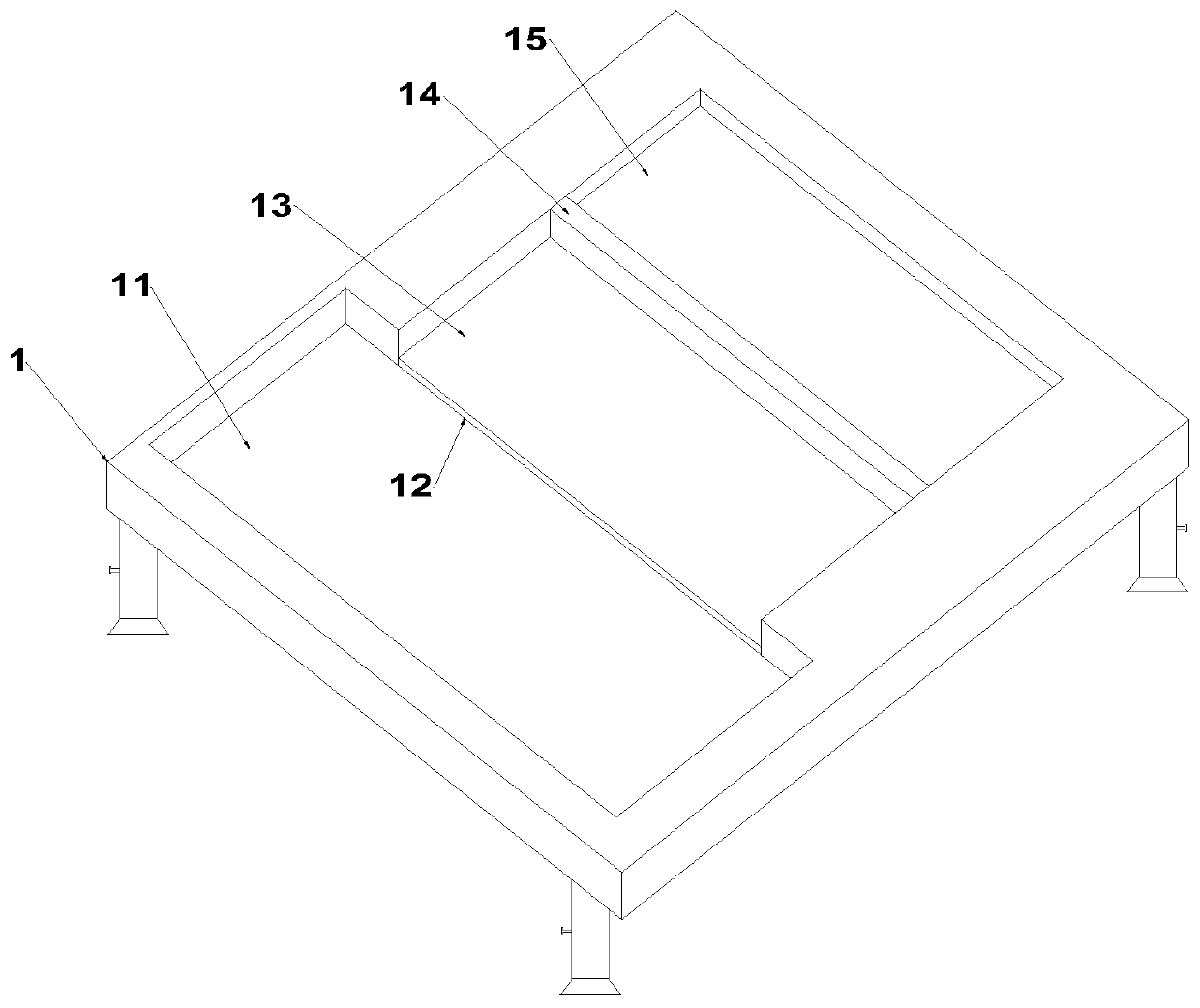

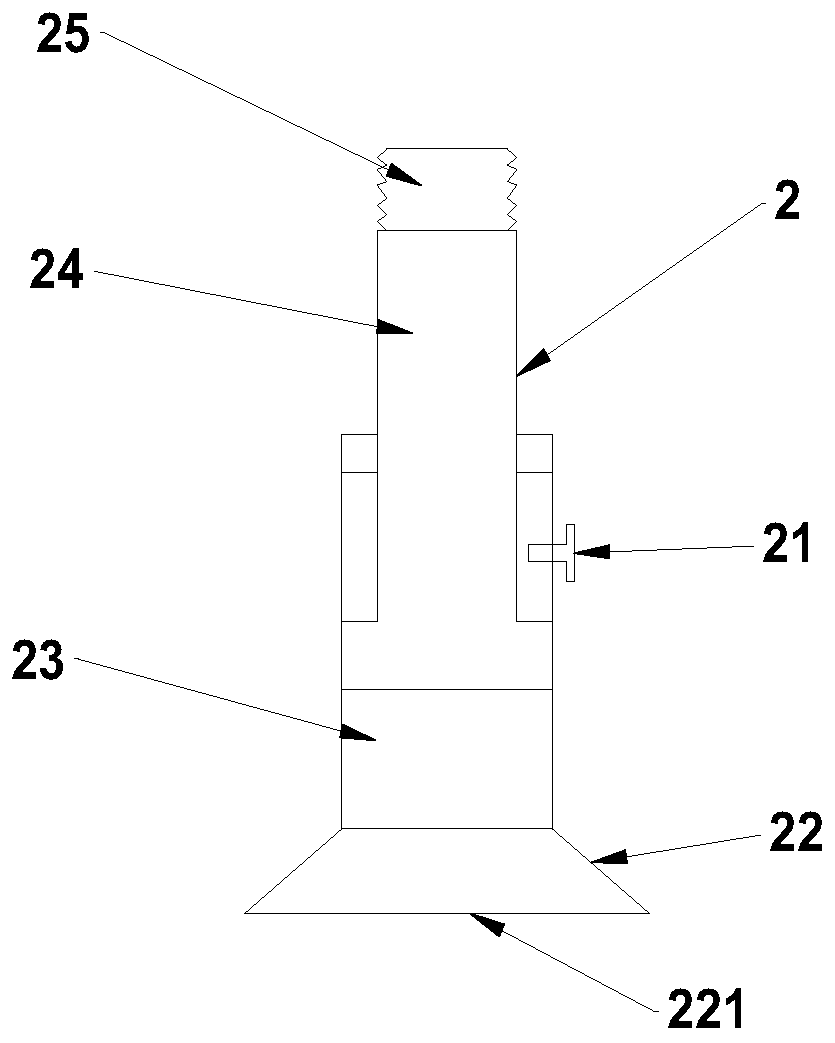

[0059] Such as Figure 1-11 As shown, in an inflatable mold provided by the present invention, the mold 5 is cylindrical; the two ends of the mold 5 are open; the cylinder wall of the mold 5 is provided with a fracture 54; the fracture 54 extends from one end of the mold 5 to the other end of the mold 5 ; Fracture 54 disconnects the cylinder wall of mold 5;

[0060] Several air pressure expansion rods 52 are arranged on the two side walls of the fracture 54 successively from left to right, and the first and last ends of the air pressure expansion rods 52 are flexibly connected to the fracture 54; the air pressure expansion rods 52 communicate with the inflatable air passage 7; Inside the mold 5.

[0061] Preferably, the inflation air passage 7 includes a mold air passage 51, a mold inflation hole 53 and a sealing ring 531;

[0062] The mold air channel 51 is arranged in the cylinder wall of the mold 5; the mold air channel 51 communicates with the air pressure expansion rod 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com