Fiber tow treatment device and method

A fiber tow and processing device technology, which is applied in the field of fiber tow processing devices, can solve the problems of fiber damage and poor stability, achieve stable fiber spreading, and reduce the effect of turbulent flow on the tow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

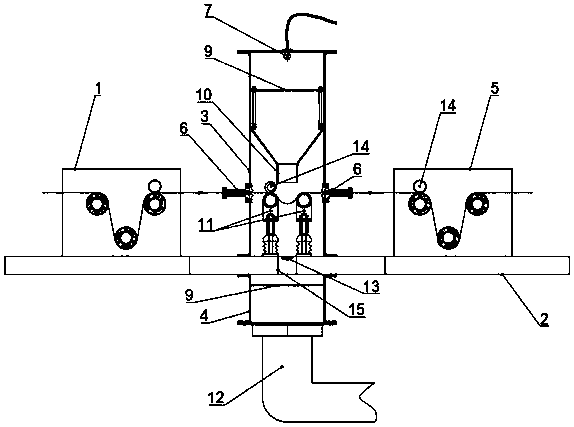

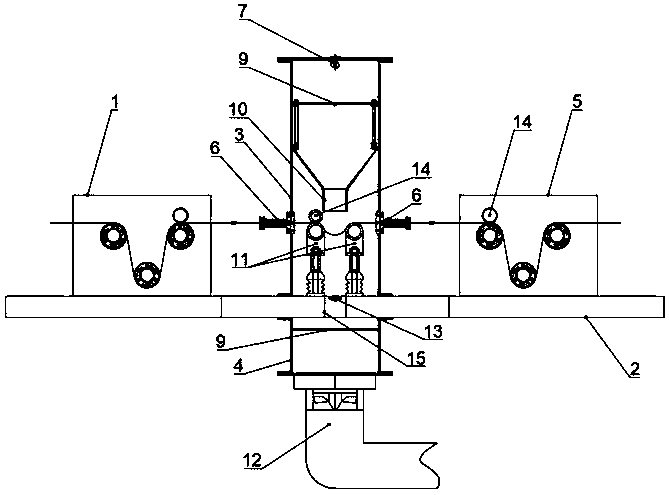

[0034] Such as Figure 1 to Figure 3 As shown, a fiber tow spreading device includes a front drawer 1, a mounting frame 2, an upper cavity 3, a lower cavity 4 and a rear drawer 5, the front drawer 1, the upper cavity 3 and the rear The tractor 5 is arranged on the upper surface of the mounting frame 2 successively from left to right, and the fiber inlet / outlet ports of the front tractor 1, the upper cavity 3 and the rear tractor 5 are located on the same horizontal straight line, and the lower cavity 4 is arranged on the lower surface of the mounting frame 2, and corresponds to the position of the upper cavity 3, the mounting frame 2 is provided with an airflow guide hole 15 passing through the upper cavity 3 and the lower cavity 4, and the airflow The guide hole 15 is located in the middle of the cavity, and an anemometer 13 is arranged in the air flow guide hole 15 for measuring the wind speed passing through the air flow guide hole 15. Fiber outlets are provided with a lab...

Embodiment 2

[0040] Such as Figure 1 to Figure 3 As shown, a processing device for fiber tow includes a front drawer 1, a mounting frame 2, an upper cavity 3, a lower cavity 4 and a rear drawer 5, and the front drawer 1, the upper cavity 3 and the rear The tractor 5 is arranged on the upper surface of the mounting frame 2 successively from left to right, and the fiber inlet / outlet ports of the front tractor 1, the upper cavity 3 and the rear tractor 5 are located on the same horizontal straight line, and the front traction Press roller 14 is arranged above the drafting rollers of machine 1 and rear traction machine 5, and described press roller 14 is a rubber roller, which can play the role of increasing drafting force and positioning tow. The friction force on the tow can be increased by the rubber roller, so as to ensure the stability of the tow when it travels. The lower cavity 4 is arranged on the lower surface of the mounting frame 2, and corresponds to the position of the upper cav...

Embodiment 3

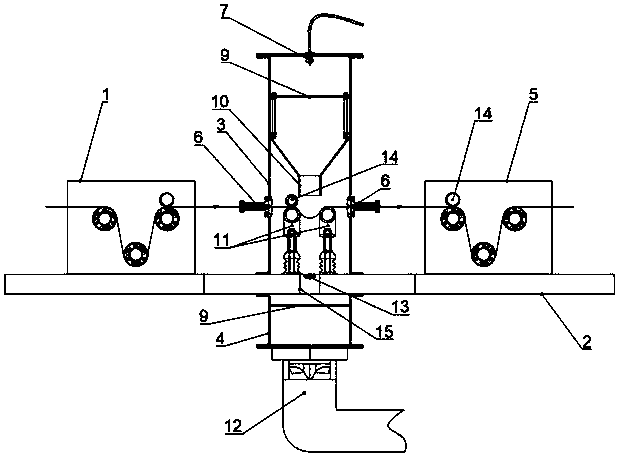

[0046] Such as figure 2 , Figure 4 , Figure 5 As shown, a processing device for fiber tow includes a front drawer 1, a mounting frame 2, an upper cavity 3, a lower cavity 4 and a rear drawer 5, and the front drawer 1, the upper cavity 3 and the rear The tractor 5 is arranged on the upper surface of the mounting frame 2 successively from left to right, and the fiber inlet / outlet ports of the front tractor 1, the upper cavity 3 and the rear tractor 5 are located on the same horizontal straight line, and the front traction Press roller 14 is arranged above the drafting rollers of machine 1 and rear traction machine 5, and described press roller 14 is a rubber roller, which can play the role of increasing drafting force and positioning tow. The friction force on the tow can be increased by the rubber roller, so as to ensure the stability of the tow when it travels. The lower cavity 4 is arranged on the lower surface of the mounting frame 2, and corresponds to the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com