Roadheader equipped with high-pressure water jet-mechanical coupling integrated disc hob

A high-pressure water jet, integrated technology, used in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of limited driving efficiency of roadheaders and low tool coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

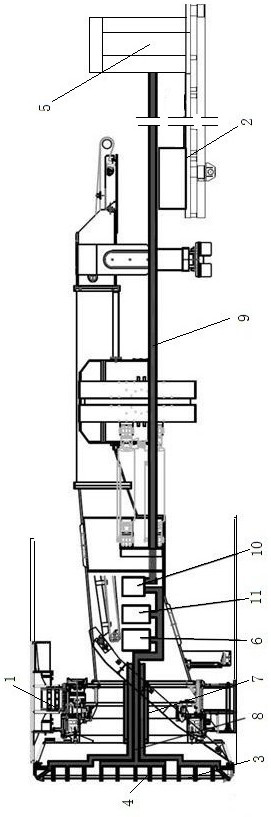

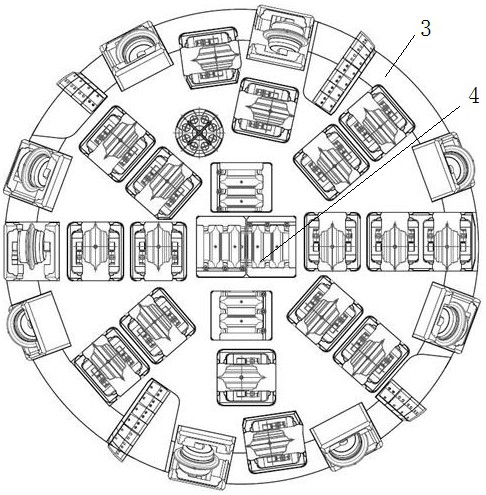

[0030] Example 1, such as figure 1 As shown, a roadheader equipped with a high-pressure water jet-mechanical coupling integrated disc hob includes a roadheader 1, ancillary equipment 2 and a slag cleaning system. The above-mentioned technical features can adopt the components on the existing roadheader. The excavation main engine 1 includes a cutter head 3, and the cutter head is connected with the main drive provided in the excavation main engine to provide the power for the rotation of the cutter head. The rear supporting equipment 2 is provided with a high-pressure water system, and the cutter head 3 is provided with an integrated disc-shaped hob 4, the high-pressure water system is connected with the integrated disc-shaped hob 4, and the integrated disc-shaped hob 4 provides High-pressure water forms a high-pressure water jet-mechanical coupling integrated disc hob, which realizes a high degree of cooperation between high-pressure water jet and self-rotating cutters, and h...

Embodiment 2

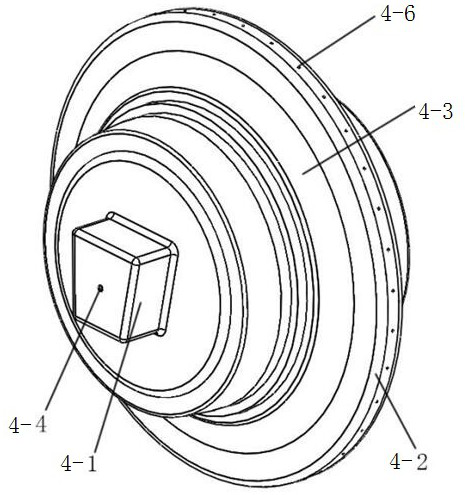

[0033] Example 2, such as Figure 3~6As shown, a roadheader carrying a high-pressure water jet-mechanical coupling integrated disc hob, the high-pressure water inlet channel 4 includes an axial water inlet channel 401 and several radial water inlet channels 402, the axial The water inlet channel 401 communicates with the rotating high-pressure pipe 8, and the high-pressure water in the rotating high-pressure pipe 8 enters into the axial water inlet channel. The radial water inlet channel 402 communicates with the axial water inlet channel 401 to realize the reversing of the high pressure water from the axial direction to the radial direction. The central axis of the axial water inlet channel 401 coincides with the central axis of the cutter shaft 4-1, and the radial water inlet channel 402 is located on the same cross section of the cutter shaft 4-1. That is, the radial water inlet channels are arranged in a divergent shape, and the number of radial water inlet channels is th...

Embodiment 3

[0037] Embodiment 3, a rock-breaking method of a roadheader carrying a high-pressure water jet-mechanical coupling integrated disc hob, such as Figure 7 shown, including the following steps:

[0038] S1: The high-pressure water outlet channel on the cutter shaft is connected to the rotating high-pressure pipe 8 of the high-pressure water system;

[0039] S2: During the tunneling process of the roadheader, the high-pressure water of the high-pressure water system enters the high-pressure water inlet channel through the fixed high-pressure pipe 9, the high-pressure rotary joint 7 and the rotating high-pressure pipe 8 under the action of the high-pressure pump group 5 and the booster device 6, and then The high-pressure water jet is sprayed out through the high-pressure water distribution channel and the high-pressure water outlet channel to impact the rock surface, causing cracks on the rock surface, and then the hob crushes the rock surface to break the rock, realizing high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com