Carbon nano-tube film transducer array

A carbon nanotube film, transducer array technology, applied in nanotechnology, fluids utilizing vibration, etc., can solve the problems of reduced sensitivity of transducer arrays, increased manufacturing costs, signal crosstalk, etc., to reduce time costs and economy. Cost, avoidance of resonance effects, effect of high thermoacoustic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

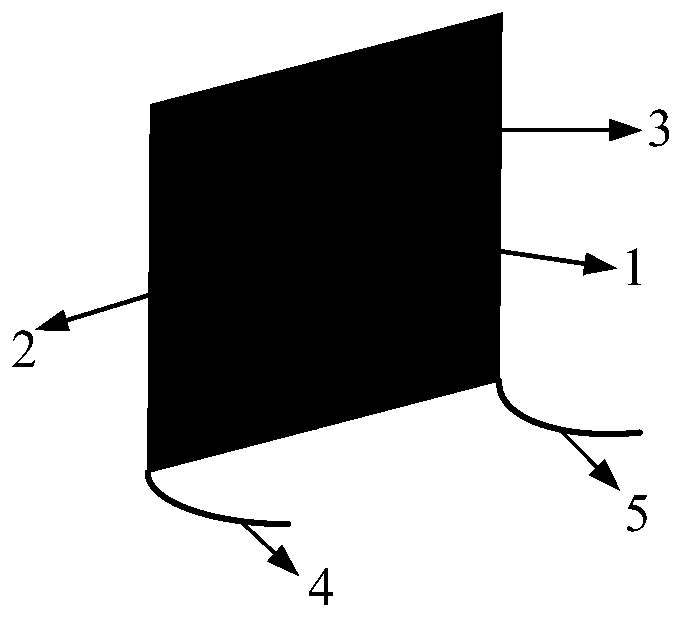

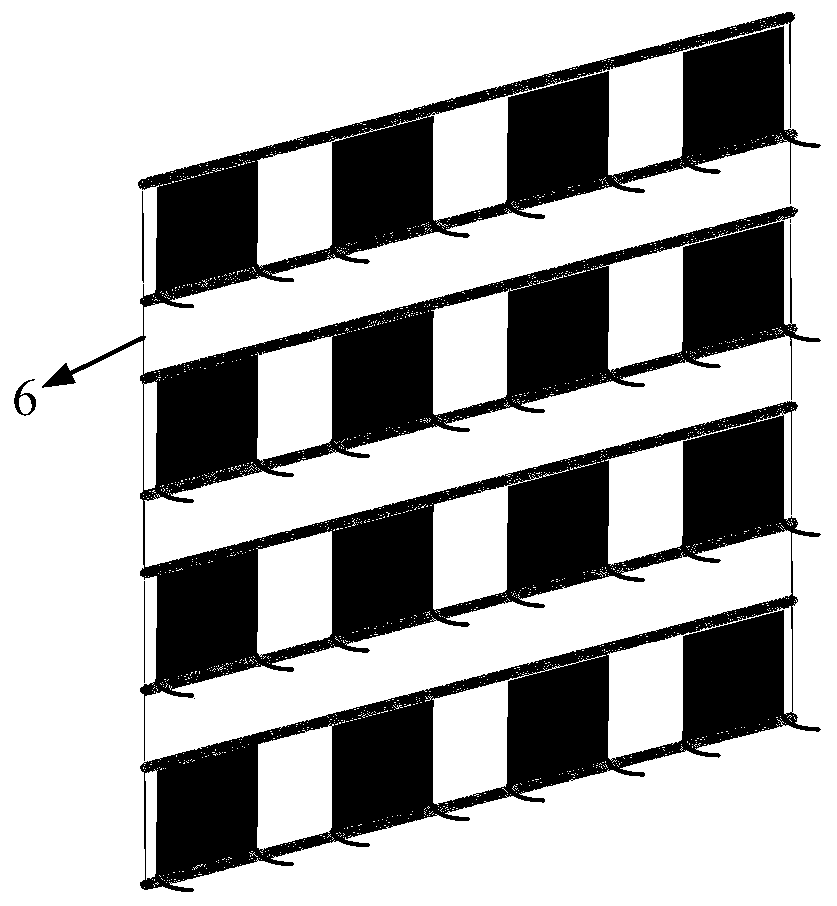

[0023] The carbon nanotube film 1 of the sounding element is a square with a side length of 2 millimeters, the metal electrode A2 and the metal electrode B3 are made of copper, the wire a4 and the wire b5 are copper wires, and the transducer array frame 6 All are hard heat-resistant insulating plastics. Apply methanol evenly on the junction of metal electrode A2, metal electrode B3 and carbon nanotube film 1, then paste metal electrode A2 and metal electrode B3 on both sides of carbon nanotube film 1 and wait for methanol to dry to realize metal electrode Fixed connection with carbon nanotube film 1. Solder the wire a4 and the wire b5 to the metal electrode A2 and the metal electrode B3 respectively with an electric soldering iron. Fix and paste the metal electrode A2 and the metal electrode B3 on the transducer array frame 6 with glue.

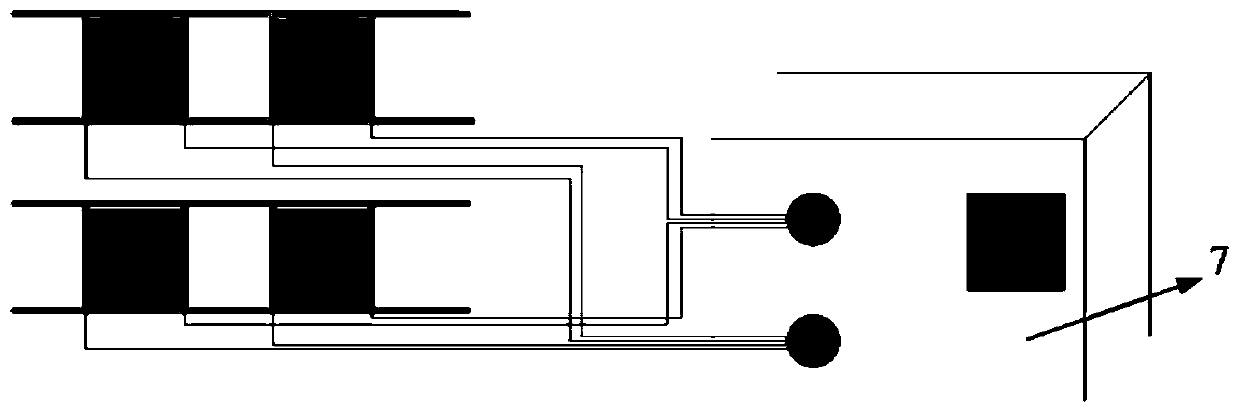

[0024] The transducer array frame 6 is a planar structure, which contains a total of 64 sounding elements arranged in 8 rows and 8 columns...

Embodiment 2

[0026]The transducer array frame 6 is a planar structure, which contains a total of 100 sounding elements arranged in 10 rows and 10 columns. The assembly method of each sounding element is the same as that of Embodiment 1. The distance between adjacent sounding elements is 2.5 mm, and the sound frequency is 100,000 Hz, the input power of each sound generating element is 0.01 watts, and the sound transmission medium is air at room temperature. In the sound field radiated by the transducer array based on the thermoacoustic effect, on the hemispherical observation surface 0.5 meters away from the center of the transducer array, the main lobe width of the sound field is 16.09 degrees, and the maximum sound pressure level is 81.25 decibels.

Embodiment 3

[0028] The transducer array frame 6 has a spherical structure and contains a total of 100 sounding elements arranged in 10 rows and 10 columns. The assembly method of each sounding element is the same as that in Embodiment 1, and the sound frequency is 100,000 Hz. The input of each sounding element The power is 0.01 watts, and the sound transmission medium is air at room temperature. In this embodiment, on a hemispherical observation surface 0.025 meters away from the center of the transducer array, the main lobe width of the sound field is 17.06 degrees, and the maximum sound pressure level is 107.27 decibels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com