A manned lifting device for building wall inspection and repair

A technology of lifting device and wall, applied in the direction of lifting device, etc., can solve the problems of secondary damage to the wall, poor stability, low safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

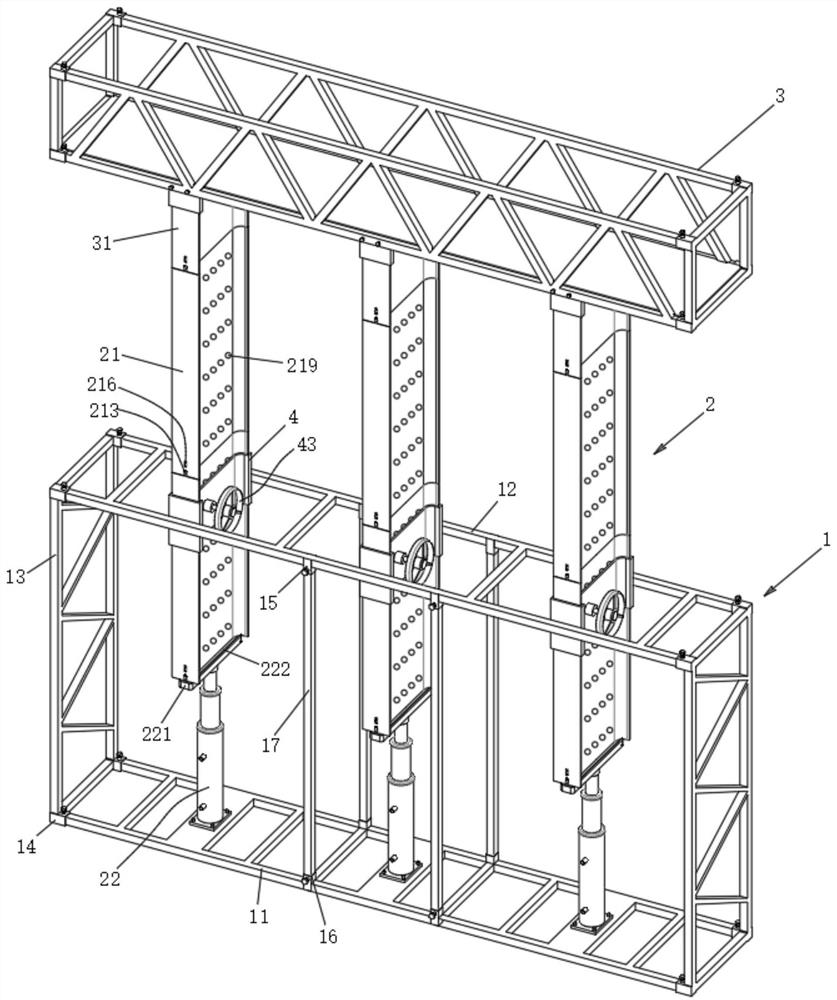

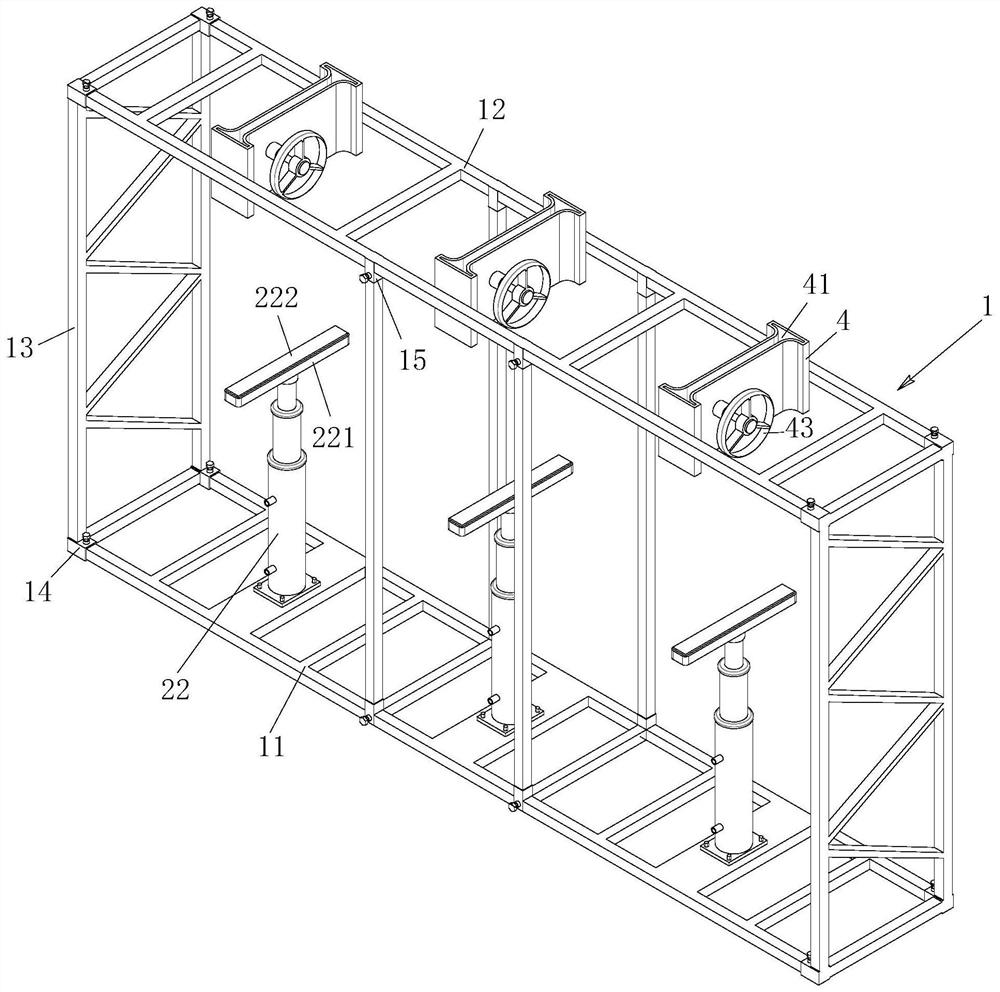

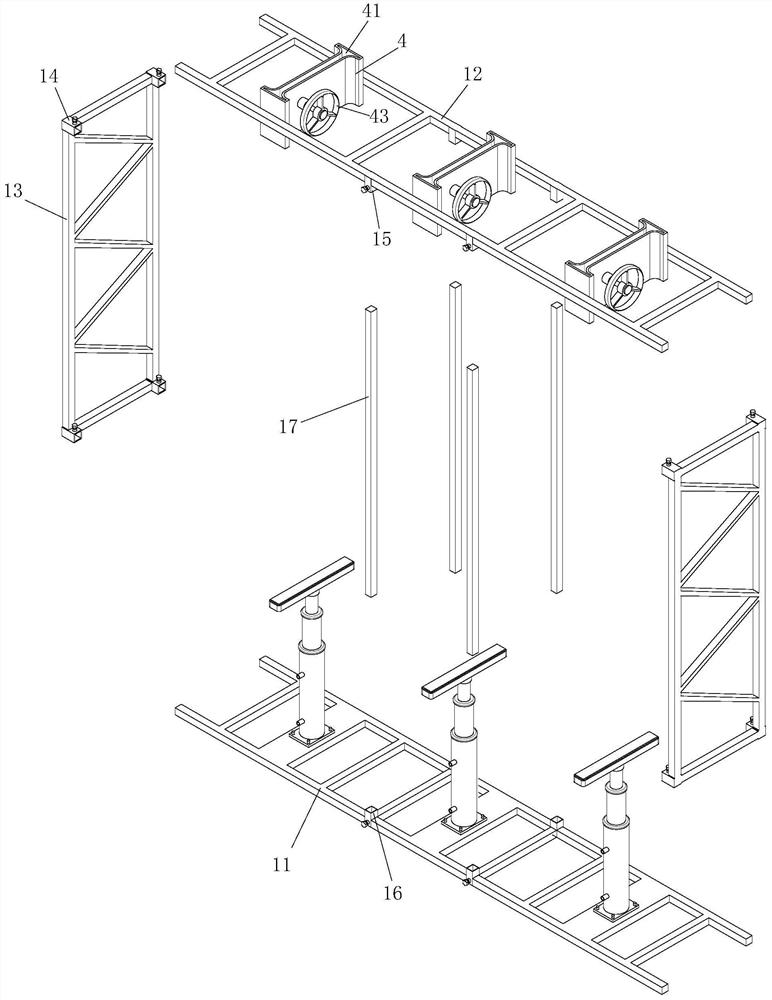

[0040] see figure 1 , the present invention provides a manned lifting device for detection and repair of building walls. The manned lifting device for detection and repair of building walls includes: a supporting steel frame 1 and a bearing steel frame 3, the bearing steel frame 3 is located above the supporting steel frame 1, and At least one set of lifting components 2 is arranged between the two, and the top of the supporting steel frame 1 is provided with a lifting support block 4 for supporting the lifting components 2;

[0041] The lifting assembly 2 consists of a linear drive mechanism 22 and a lifting support part;

[0042] The linear drive mechanism 22 is a kind of telescopic oil cylinder, telescopic air cylinder and electric telescopic cylinder, and is detachably connected to the bottom of the supporting steel frame 1 by bolts. The output end of the linear drive mechanism 22 is fixedly provided with a supporting plate 221. 221 is a strip shape, which is used to incr...

Embodiment 2

[0062] see Figure 8 and 9 , preferably, the manned lifting device for building wall detection and repair of the present invention also includes a lifting auxiliary mechanism for assisting the lifting and lowering of the supporting part;

[0063] The lifting auxiliary mechanism includes a rotating drive part 5, which can be an electric motor or a hydraulic motor. The output end of the rotating drive part 5 is fixedly connected to a gear 51, and the lifting support plate 21 is embedded in one side of the corresponding rotating drive part 5. A rack 52 is welded, the gear 51 and the rack 52 mesh with each other, and the rack 52 continues to the two ends of the lifting support plate 21, so that the spliced lifting support has a continuous transmission rack.

[0064] Specifically, during use, by starting the control switch for controlling the rotating driving part 5, the rotating driving part 5 is put into working state, and the lifting and lowering support part is slowly driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com