Dosing valve

A metering valve and nozzle technology, applied in the field of metering valves, can solve the problems of increased wear and achieve the effect of improving spring force and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

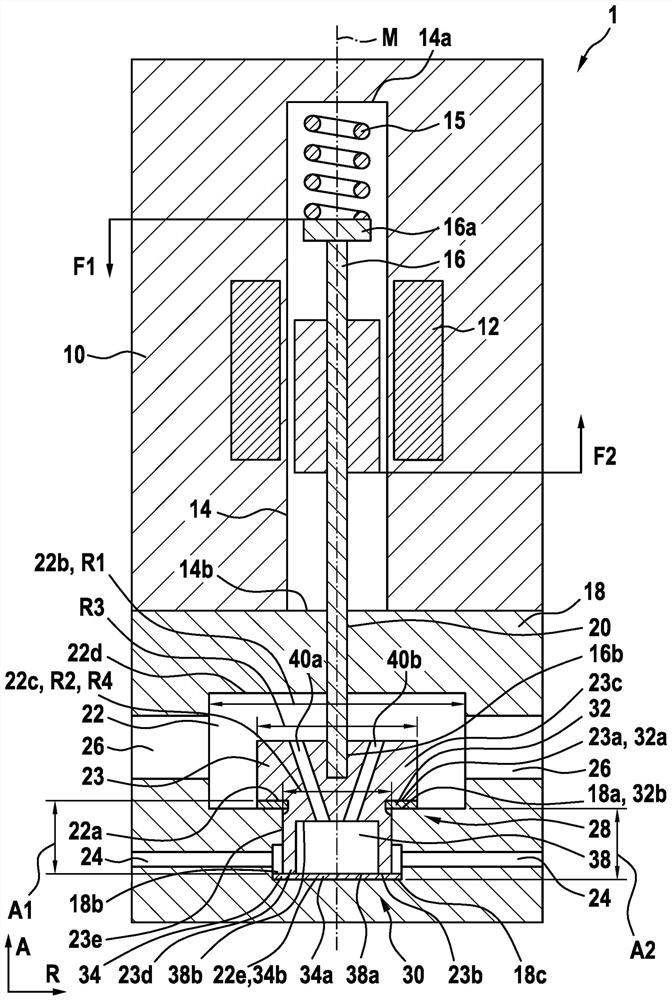

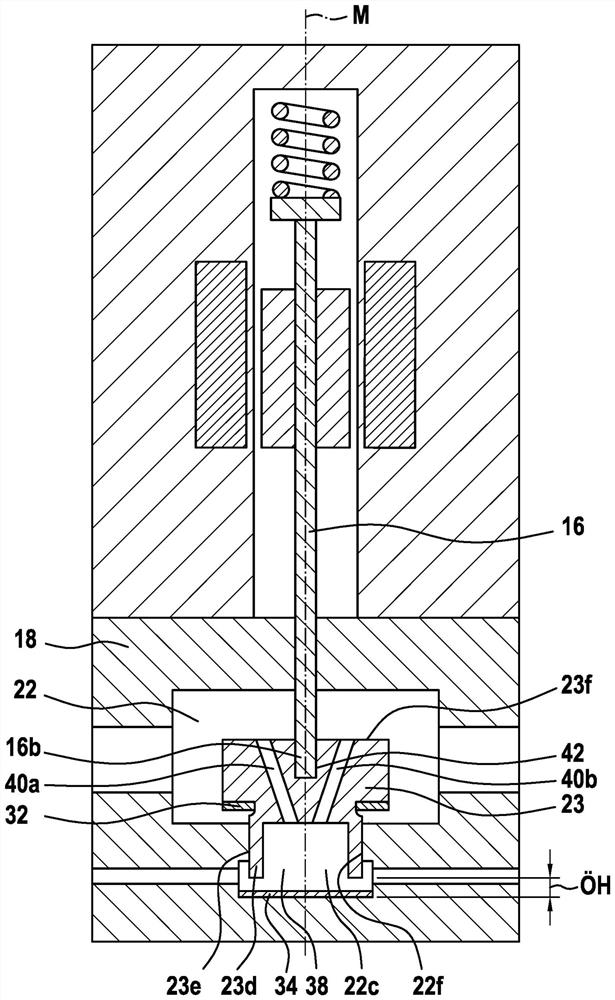

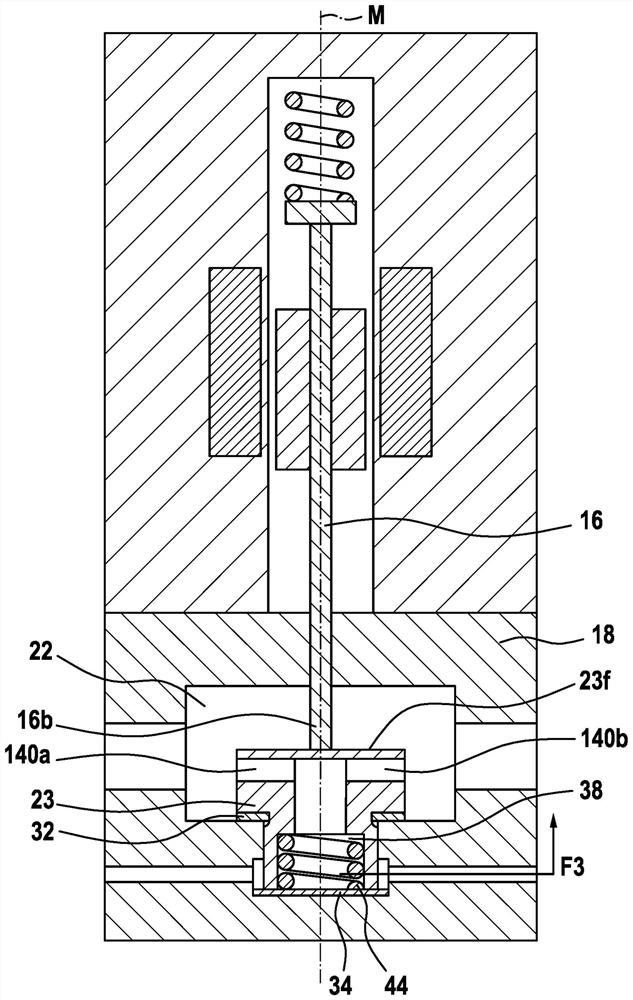

[0031] figure 1 A cross-sectional view of a metering valve for supplying gas to a fuel cell according to a preferred embodiment of the invention is shown in the closed state.

[0032]The metering valve 1 for supplying gas to a fuel cell has a base body 10 . An electromagnet 12 is arranged in the base body 10 . The base body 10 has a blind hole 14 , on a closed end 14 a of which a first spring element 15 is supported. Furthermore, the metering valve 1 has a plug-in armature 16 which is displaceably seated in the blind bore 14 . The plug-in armature 16 is loaded with a spring force F1 by the first spring element 15 at the first axial end section 16 a.

[0033] Furthermore, the metering valve 1 has a nozzle 18 which is connected to the base body 10 in the region of the open end 14 b of the blind hole 14 . The plug-in armature 16 is guided through a first bore 20 formed in the nozzle 18 . Furthermore, the plug-in armature 16 is connected at the second axial end section 16 b t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com