Cement additive adding and weighing control system

A cement additive and control system technology, applied in weighing, measuring devices, instruments, etc., can solve the problems of large structure, inaccurate weighing data, large occupied volume, etc., and achieve a small occupied volume, simple structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

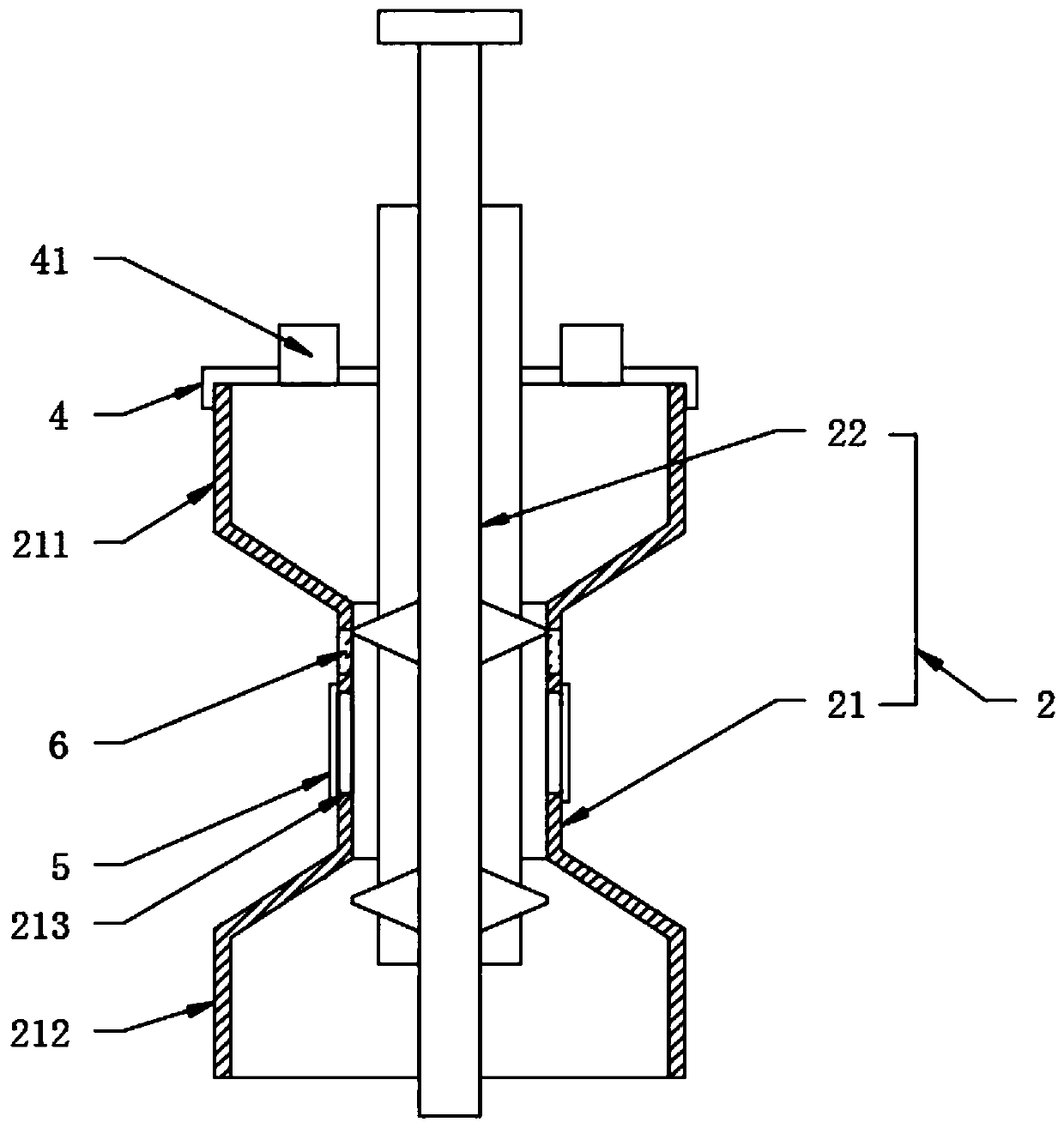

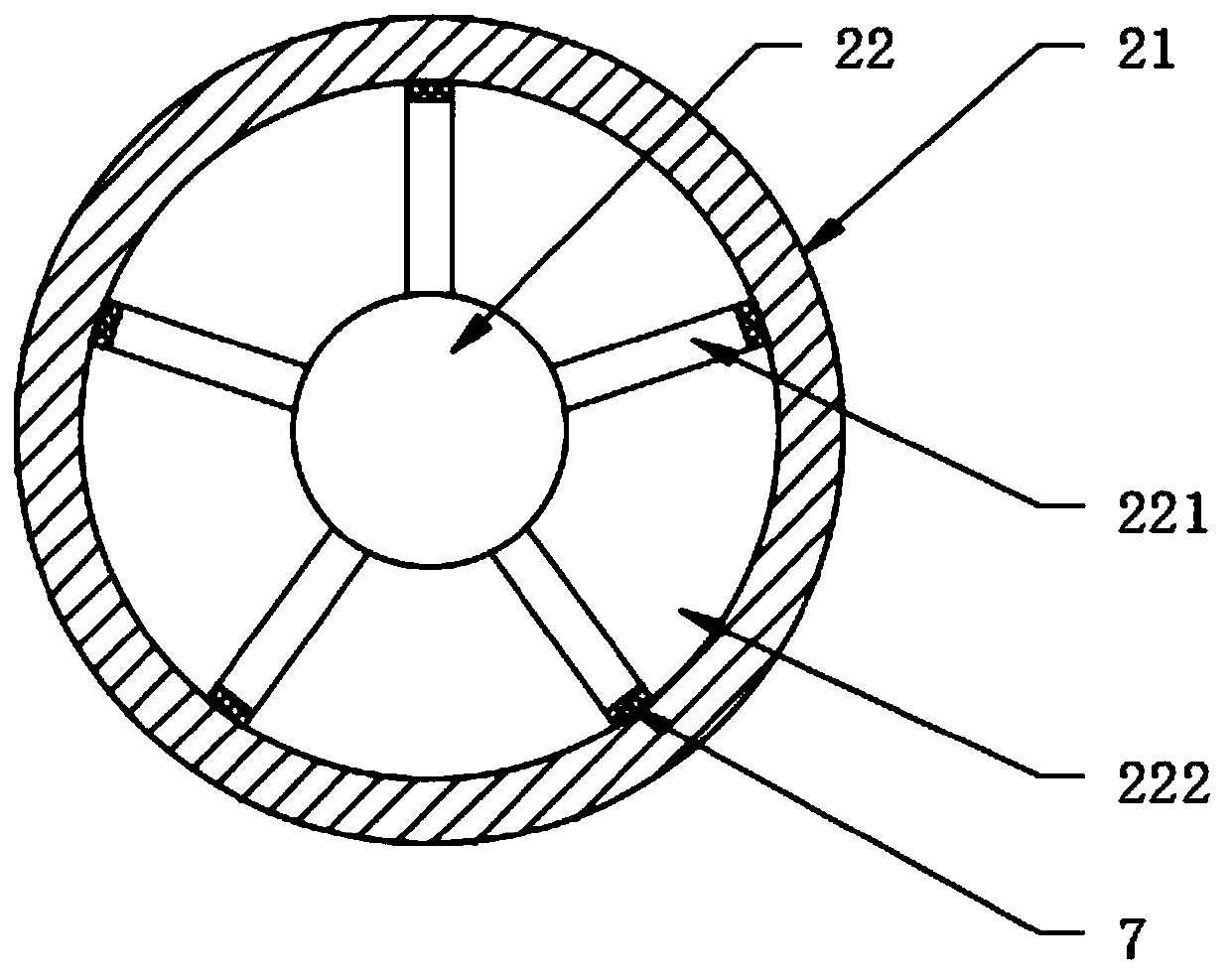

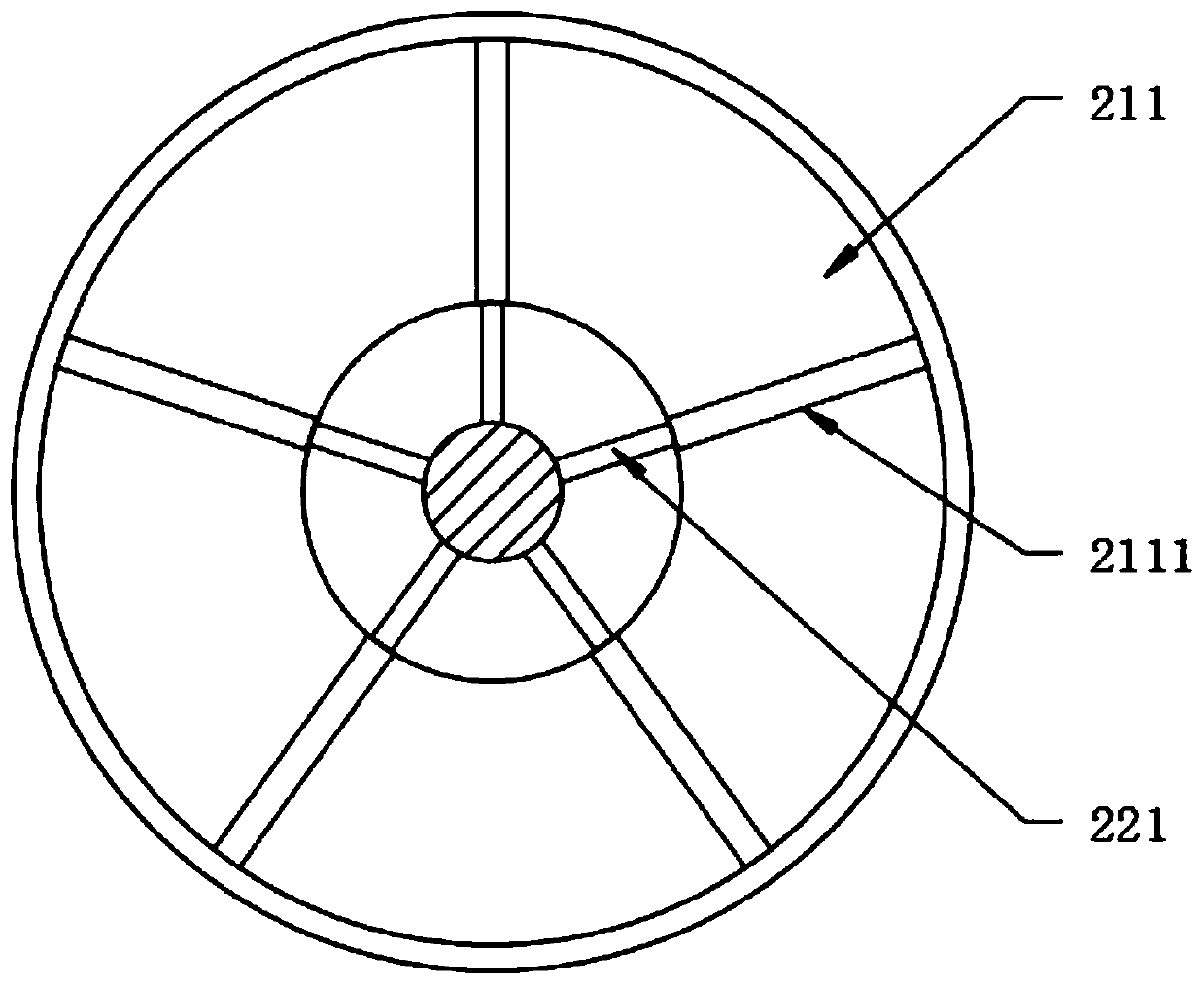

[0036] see Figure 1-5 , the present invention provides a technical solution: a cement additive weighing control system, including a pulse discharge device 2, a pulse electric telescopic rod 1 and a pulse control instrument 3, the entire control system is supported by an external support frame, and the pulse control instrument 3 is electrically connected with the pulse electric telescopic rod 1, and is used to provide pulse signals to the pulse electric telescopic rod 1, and the pulse action times per unit time of the pulse electric telescopic rod 1 can be realized through the pulse control instrument 3, and the pulse discharge device 2 includes The vertically distributed feed pipe 21 and the pulse feeding column 22 that runs through the feed pipe 21, the top of the feed pipe 21 is fixedly provided with a feed cone 211 and the bottom is fixedly provided with a discharge cone 212, the feed cone The shape cover 211 is used to place the cement additive, and the outer wall of the ...

Embodiment 2

[0038] figure 1 and Figure 4 As shown, the difference from Embodiment 1 is that the outer wall of the pulse feeding column 22 and located between two adjacent partitions 221 are provided with evenly distributed slots 2211 in the vertical direction, and one side of the weighing plate 222 is fixed A block 2221 used in conjunction with the card slot is provided, and a maintenance hole 213 is opened on the outer wall of the material guide pipe 21, and a sealing plate 5 corresponding to the maintenance hole 213 is detachably connected, and the sealing plate 5 can pass through the bolt and the material guide tube 21 outer wall connection, thus the position of the weighing plate 222 can be adjusted by opening the sealing plate 5, and then the volume between the two weighing plates 222 at the same position can be adjusted, and then the amount of single pulse feeding can be adjusted.

Embodiment 3

[0040] Such as figure 1 As shown, the difference with Embodiment 1 is that the top of the feed cone 211 is detachably connected with a cover 4, and the cover 4 is provided with evenly distributed feed pipes 41, and each feed pipe 4 and a single cement additive The discharge port is connected to facilitate feeding into the feed cone 211, while the cover 4 has the function of avoiding dust and is environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com