A kind of automatic assembly method of notebook computer

A notebook computer and assembly method technology, applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems of high cost, manpower, and poor efficiency, so as to improve production capacity and efficiency, save manpower, and improve the degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

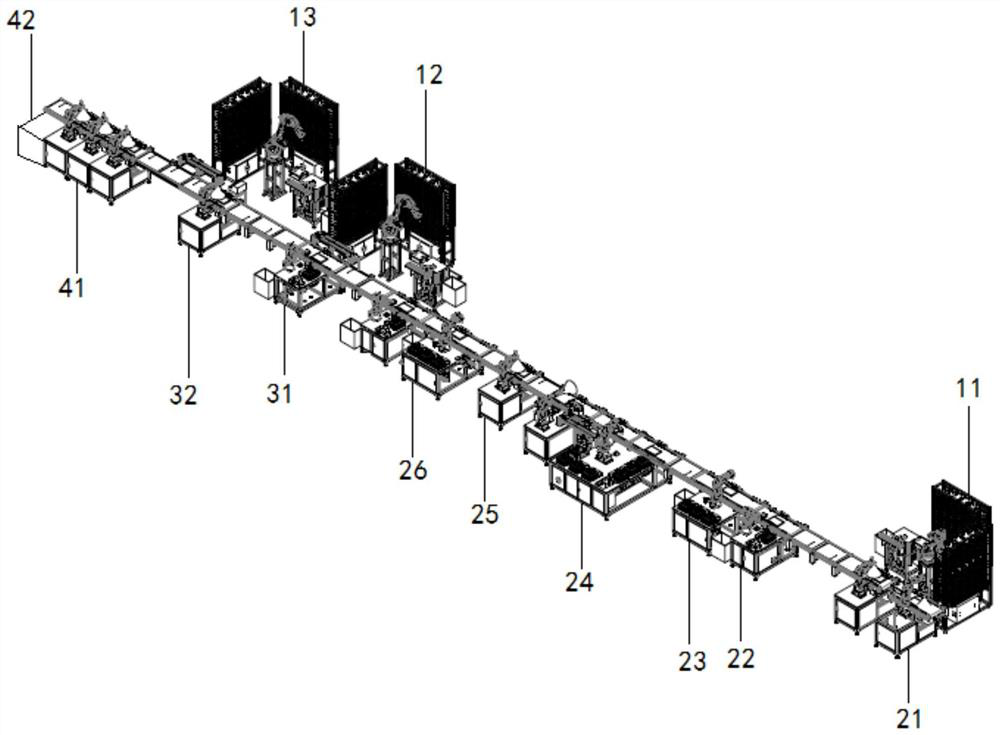

[0030] see Figure 1 to Figure 5 , the present embodiment provides an automated assembly method for a notebook computer. Three sorting modules are first provided, which include a keyboard sorting module 11, a display screen sorting module 12 and a rear cover sorting module 13. The keyboard sorting module 11 and the display screen sorting module 12 is provided with a first assembly line, between the display screen sorting module 12 and the rear cover sorting module 13 is provided with a second assembly line, and the third assembly line is provided in the second On the side of the assembly line, the first assembly line includes the assembly of circuit board components and keyboard components and the assembly of locking screws 21, the assembly module 22 of I / O boards and iron parts, the assembly module 23 of RAM cards, and the assembly of mechanical hard disks and iron parts. Assembly and locking screw 24, assembly of mechanical hard disk and flat cable, locking module of mechani...

Embodiment 2

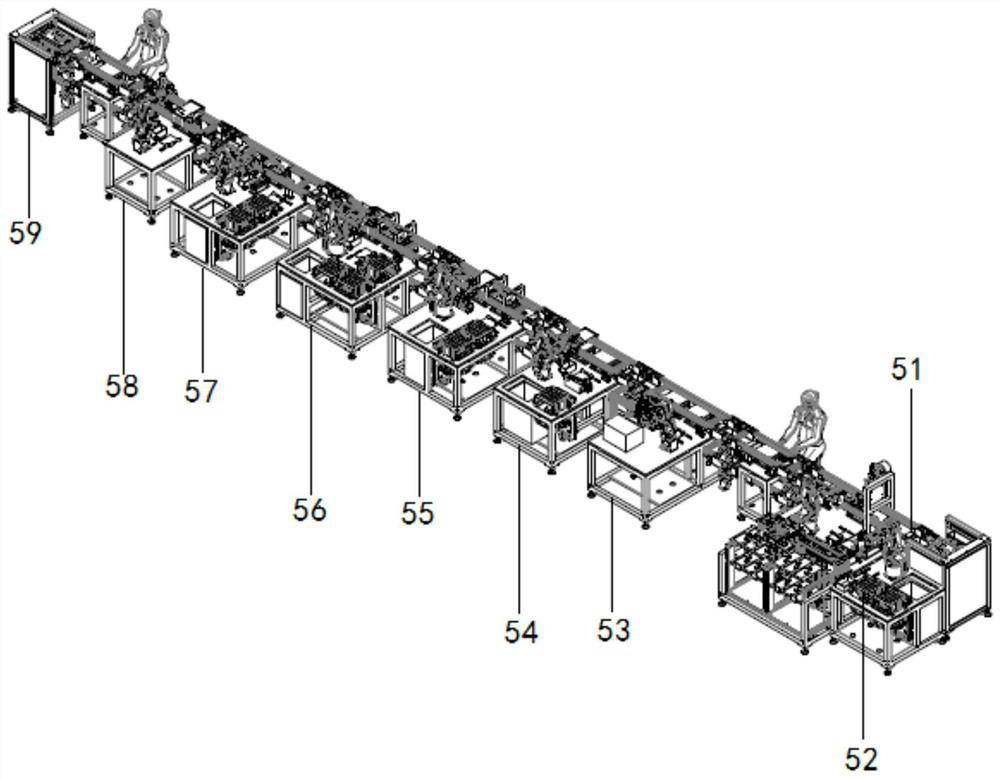

[0047] see Figure 1 to Figure 5 , the figure shows an automatic assembly method for a notebook computer provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the circuit board assembly passes The circuit board component production line is produced and formed, and the circuit board component production line includes PCB pre-processing module 51, PCB loading module 52, VGA and CPU assembly module 53, polyester film and labeling and absorbing material module 54, iron assembly Module 55, solid state hard disk card module 56, WLAN card module 57, lock screw module 58 and circuit board assembly blanking module 59, a material turning device is installed between the PCB loading module 52 and the VGA and CPU assembly module 53, turning over The material device includes a manipulator and a positioning frame. The PCB is positioned on the positioning frame, and t...

Embodiment 3

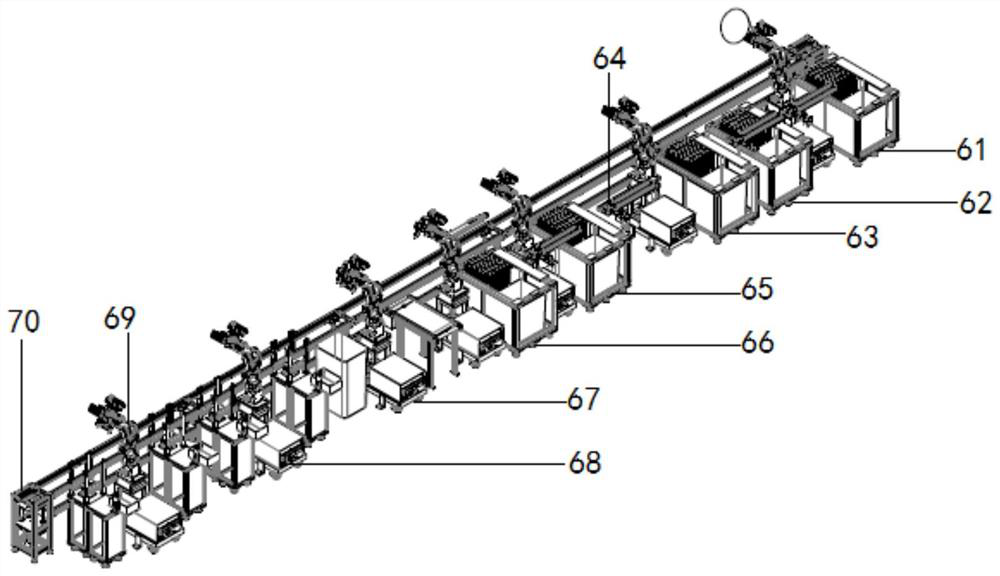

[0049] see Figure 1 to Figure 5 , the figure shows an automatic assembly method for a notebook computer provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: three sorting The module includes a keyboard sorting module 11, a display screen sorting module 12, and a rear cover sorting module 13. The sorting module is mainly composed of a manipulator and a parts storage frame. There are multiple parts to be assembled on the parts storage rack, and the manipulator plays the role of transfer. Due to the regular arrangement of parts on the parts storage rack, a positioning plate can be connected to the manipulator, and there are multiple hanging bars on the positioning plate. The positions of multiple hanging bars correspond to the positions of multiple parts, so that the manipulator can Ability to pick up multiple parts, improve transfer efficiency, and red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com