OIS motor and four-axis Tilt OIS anti-shake structure based on balls

A ball, motor technology, applied in the field of TiltOIS anti-shake structure, can solve the problem of single anti-shake axis, difficult to achieve Shitf anti-shake and Tilt anti-shake and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

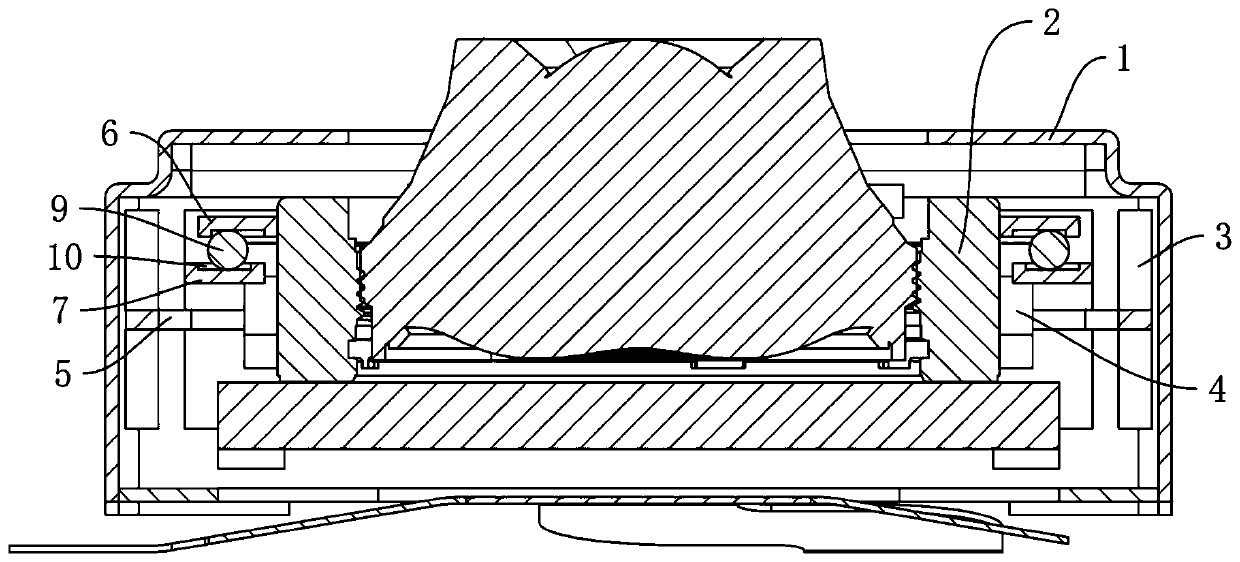

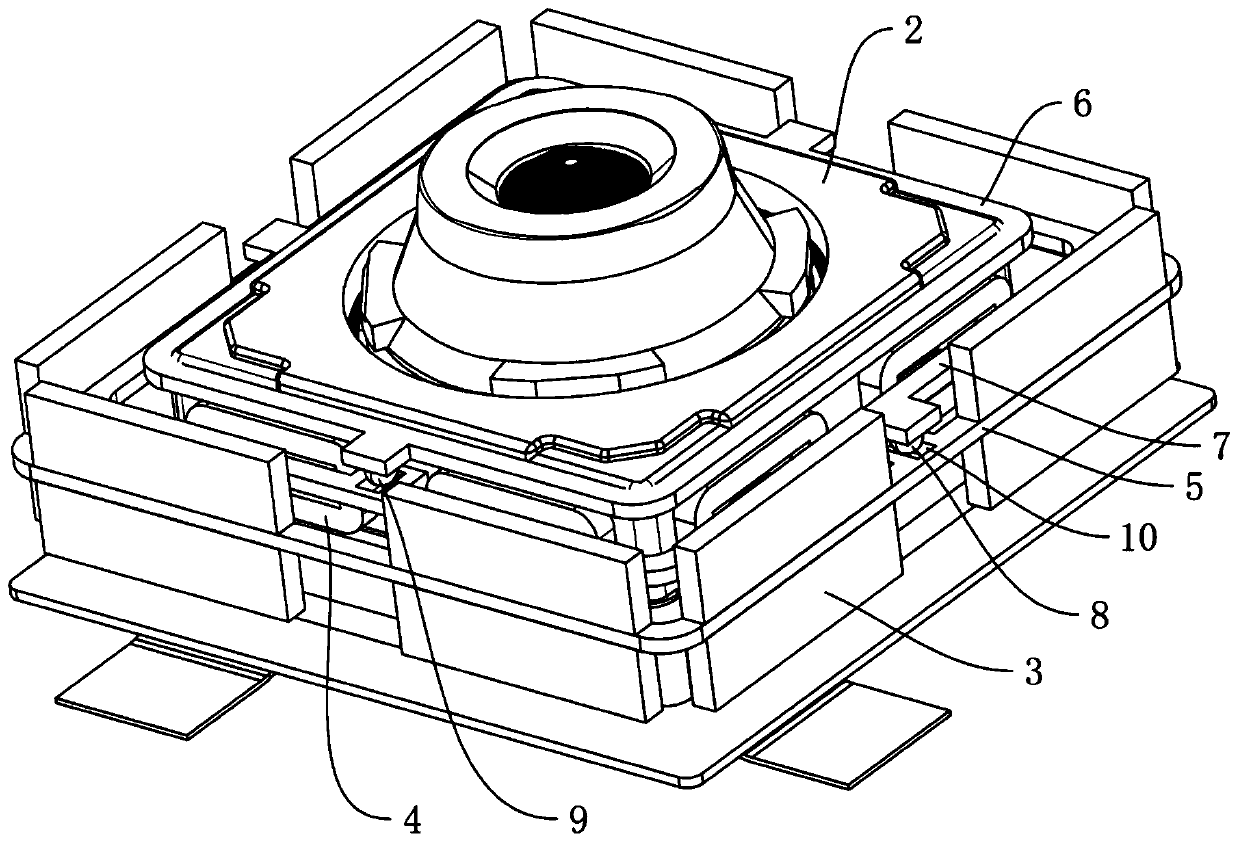

[0023] Embodiment 1: as Figure 1 to Figure 3 As shown, a ball-based four-axis Tilt OIS anti-shake structure proposed by the present invention includes a housing 1, a lens holding device 2 arranged in the inner cavity of the housing 1 (which is the prior art, and will not be described in detail here), and the housing Body and lens holding device 2 are all square. A number of magnets 3 are evenly distributed on the inner wall of the housing 1, and a number of coils 4 corresponding to the magnets 3 are evenly distributed on the side wall of the lens holding device 2. 2. The winding directions of the coils 4 on opposite side walls are set in opposite directions, and a movable mechanism for facilitating the movement of the lens holding device 2 is arranged between the housing 1 and the lens holding device 2 .

[0024] Wherein the movable mechanism includes a first bracket 5 arranged on the inner wall of the housing 1, a second bracket 6 arranged on the side wall of the lens holdi...

Embodiment 2

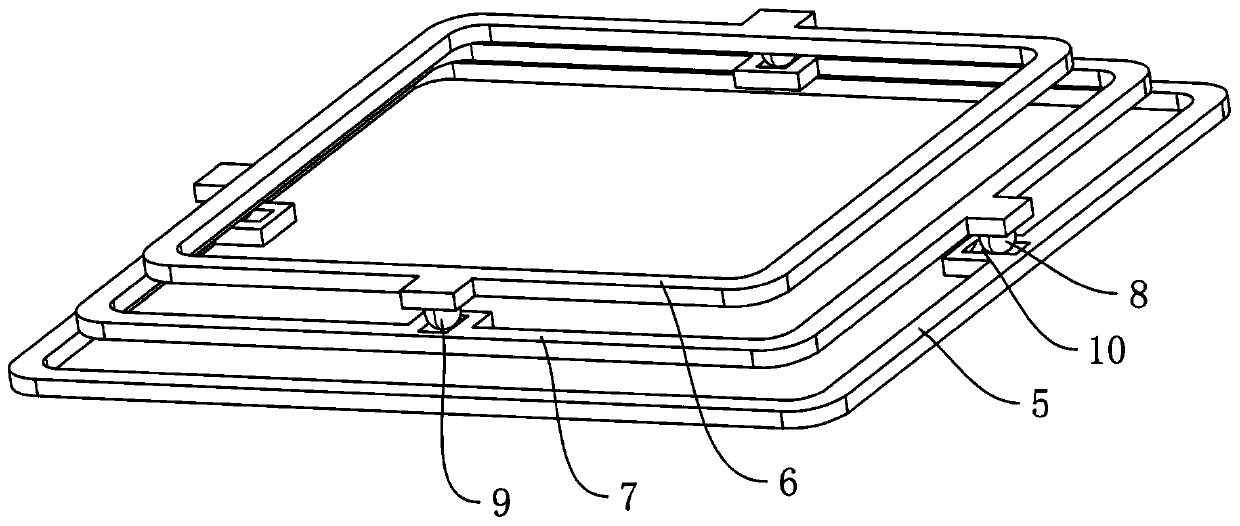

[0028] Embodiment 2: A lens holding device 2 movable mechanism in an OIS motor, such as image 3 As shown, it includes a first bracket 5 arranged on the inner wall of the housing 1, a second bracket 6 arranged on the side wall of the lens holding device 2, an intermediate bracket 7 arranged between the first bracket 5 and the second bracket 6, and at least two The first ball 8 arranged between the first bracket 5 and the middle bracket 7 to facilitate translation or flipping of the middle bracket 7, at least two second balls 9 arranged between the second bracket 6 and the middle bracket 7, the first ball 8 The arrangement direction is perpendicular to the arrangement direction of the second balls 9 .

[0029] Through the first bracket 5, the second bracket 6, the middle bracket 7, the first ball 8, and the second ball 9, the multi-angle rotation of the lens clamping device 2 is realized, and the displacement change of the lens clamping device 2 is realized at the same time, an...

Embodiment 3

[0030] Embodiment 3: An OIS motor using the ball-based four-axis Tilt OIS anti-shake structure of Embodiment 1. The OIS motor realizes Tilt anti-shake and Shift anti-shake on the X-axis and Y-axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com