Panel fastener

A technology for fixing parts and panels, applied in the directions of quick-acting fasteners, thin plate connections, connecting components, etc., can solve the problems of increased cost, complex hole shape, complicated installation of panel fixing parts, etc., and achieve the effect of simple installation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Next, embodiments of the present invention will be described using the drawings.

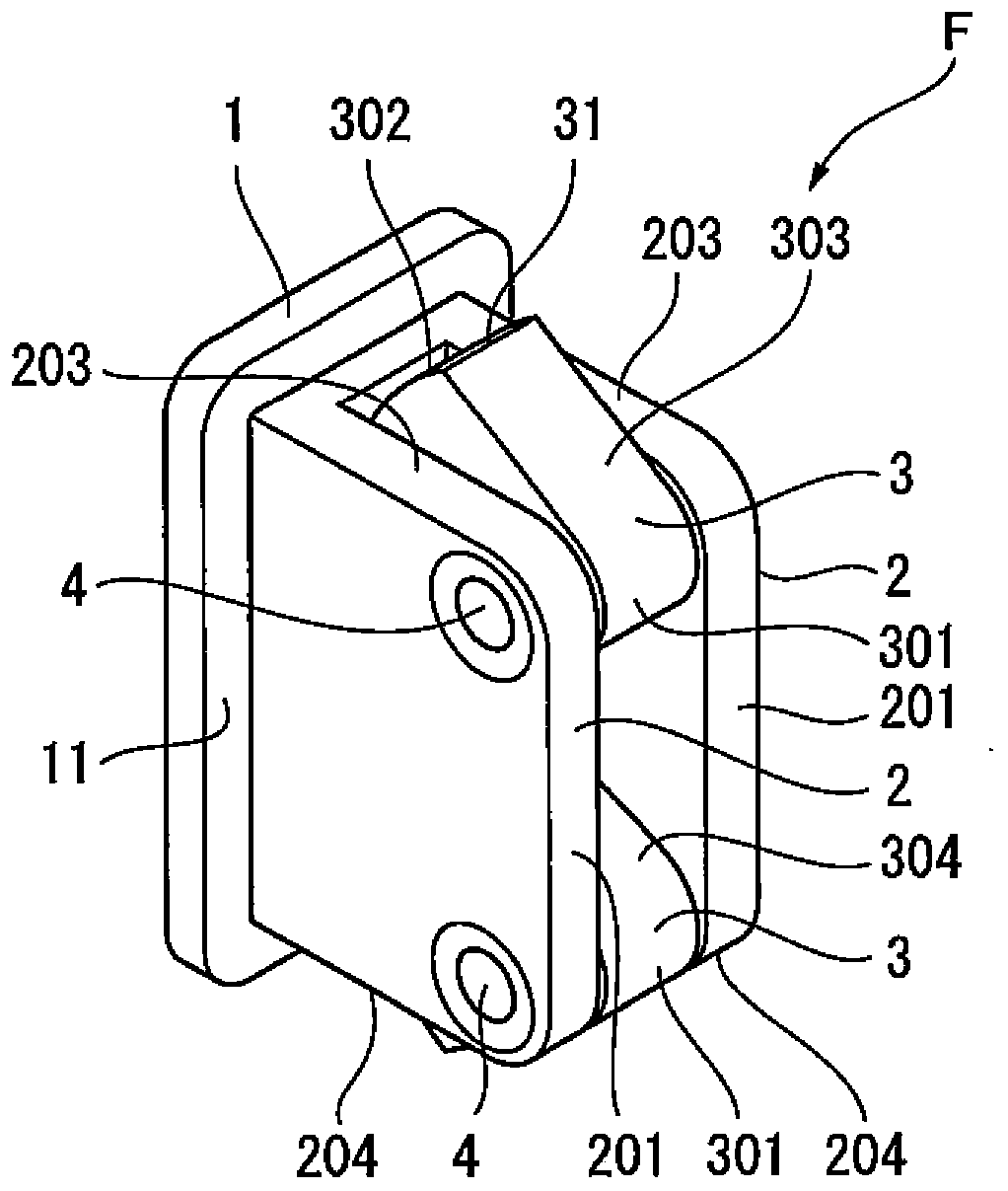

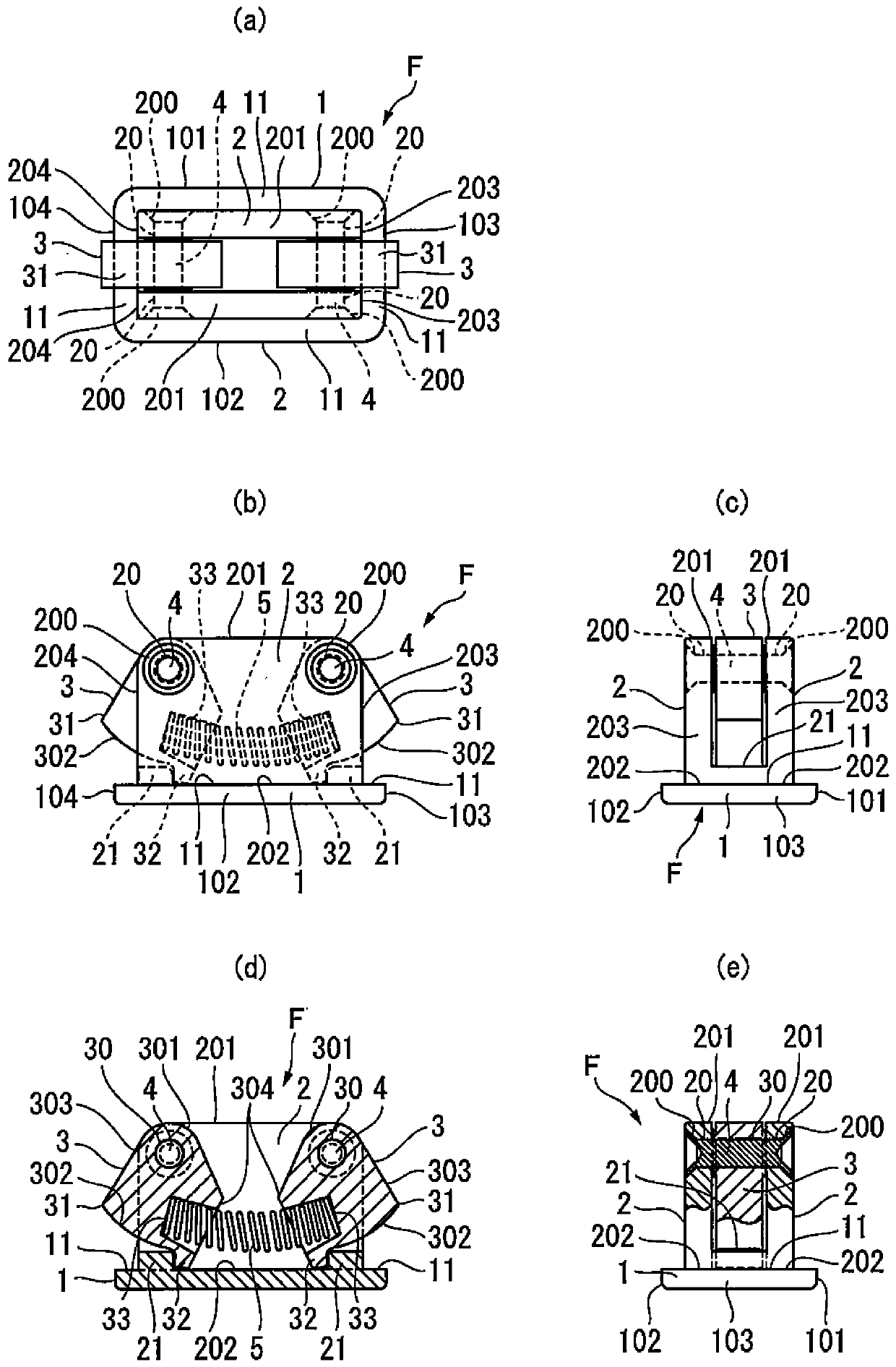

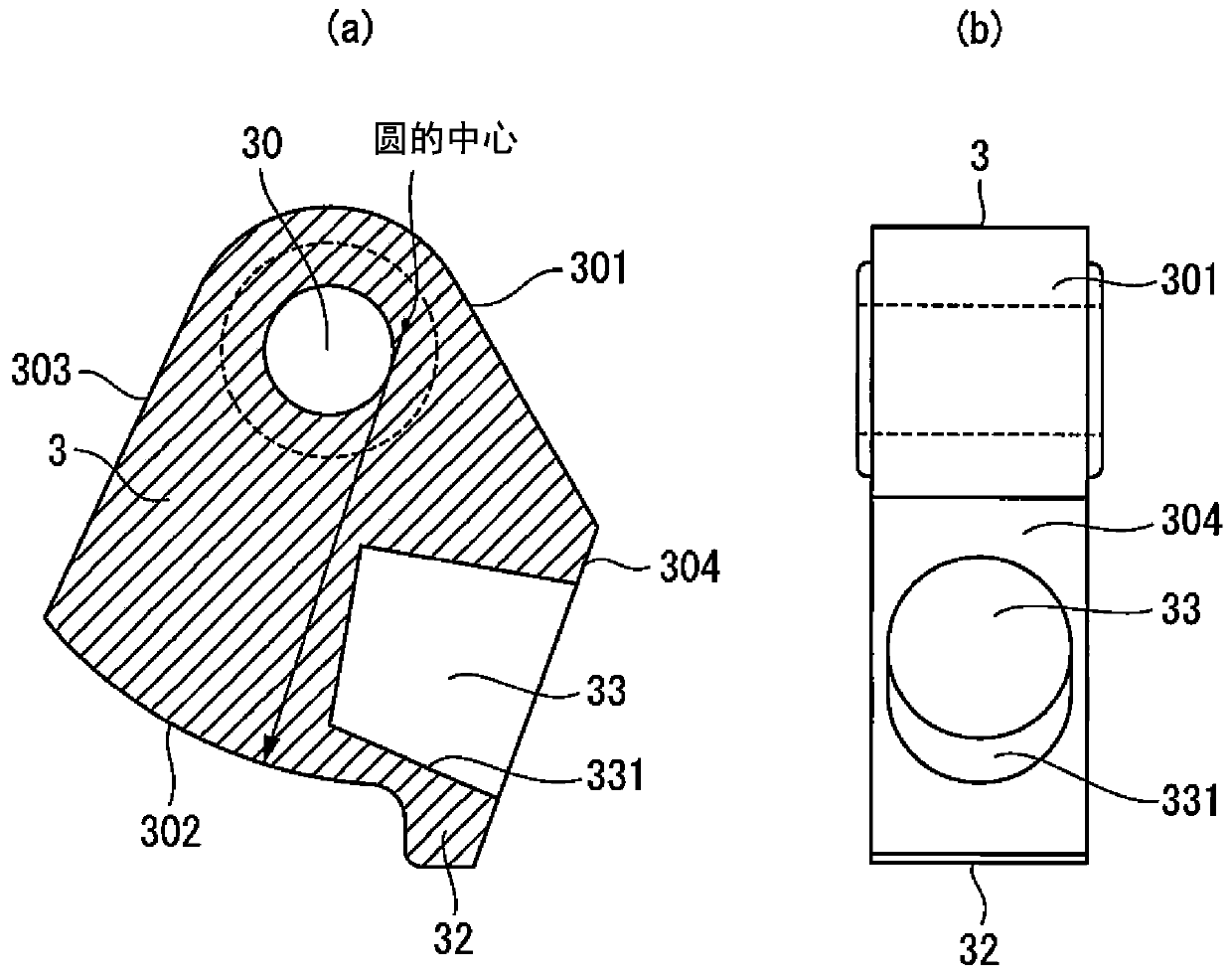

[0061] figure 1 , figure 2 Panel mount F is shown. The panel fixing member F is a component for joining the first panel P1 and the second panel P2. The panel mentioned here is a component that constitutes an assembled rack, cabinet, etc., and is made of metal or synthetic resin. limit.

[0062] In the state where the first panel P1 formed with the first mounting hole 61 and the second panel P2 formed with the second mounting hole 62 overlap each other (refer to Figure 5 ), the panel fixing member F passes through the second installation hole 62 of the second panel P2 from the first installation hole 62 of the first panel P1, and is locked on the edge of the second installation hole 62 of the second panel P2, so that the first The first panel P1 and the second panel P2 are bonded. The panel fixing part F comprises a mounting plate 1 and a pair of supporting plates 2. The above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com