Tray extension positioning method and system

A positioning method and positioning system technology, which can be used in transportation and packaging, vehicle maintenance, charging stations, etc., can solve problems such as the inability of palletized electric vehicles to be aligned, and achieve the effect of avoiding battery replacement failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

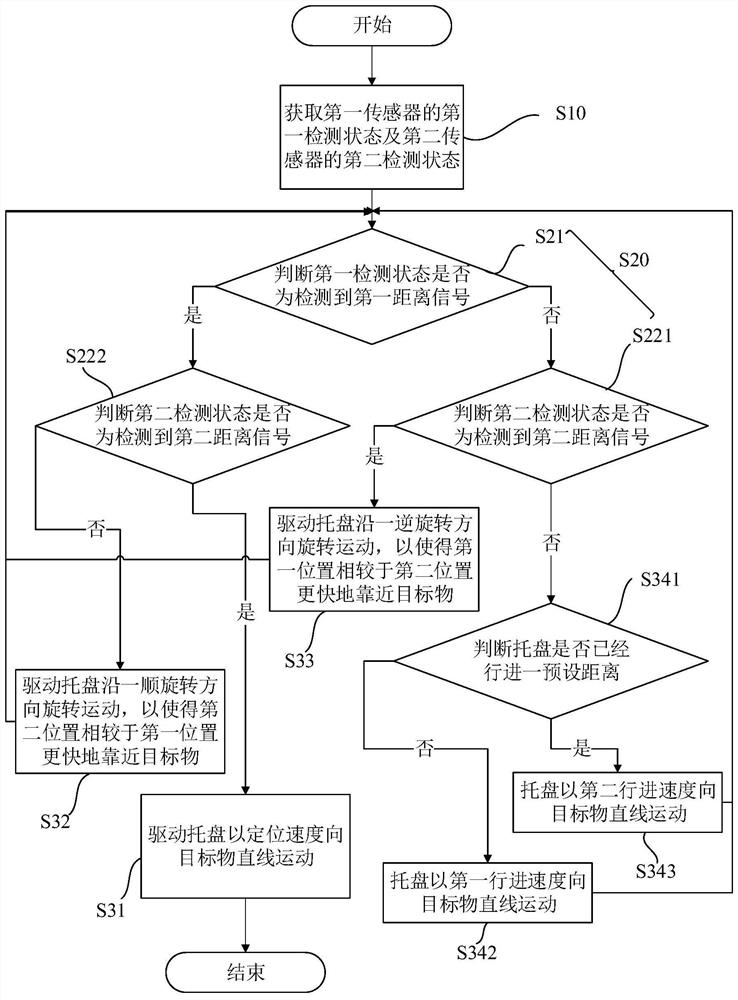

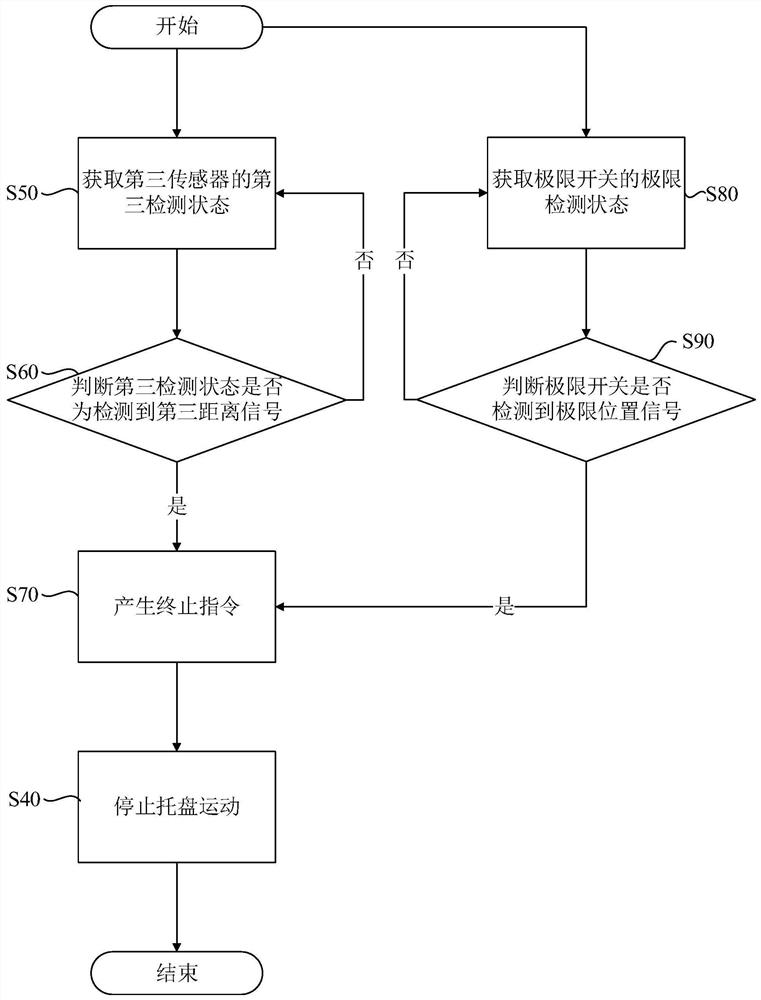

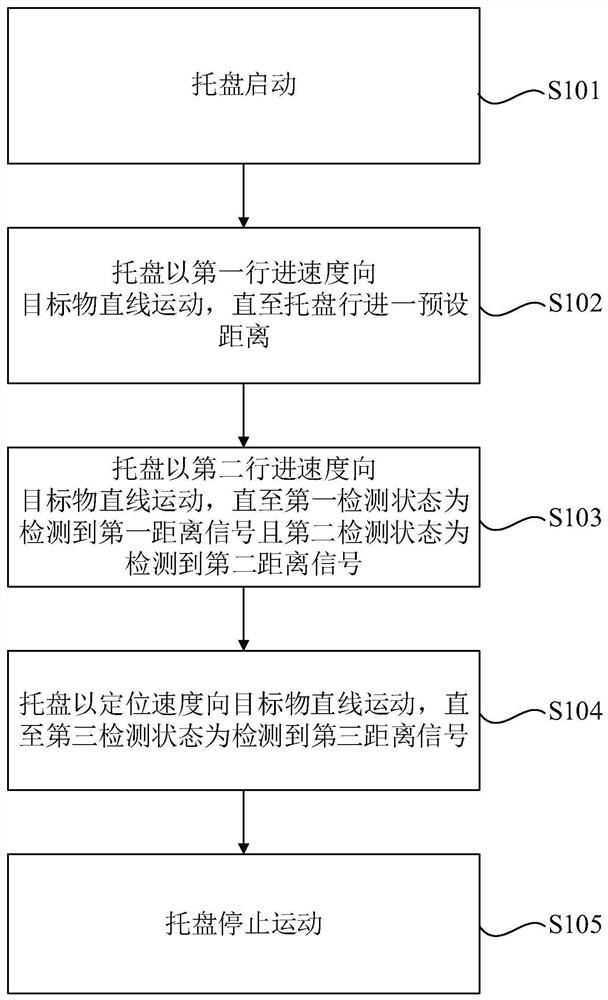

[0094] Such as Figure 1-5 As shown, the present embodiment discloses a method for positioning a tray extending out.

[0095] Such as figure 1 As shown, the pallet stretching positioning method includes the following steps:

[0096] Step S10 , acquiring a first detection state of the first sensor and a second detection state of the second sensor. The first detection state is used to indicate whether the first sensor detects the first distance signal, and the second detection state is used to indicate whether the second sensor detects the second distance signal. The first distance signal is used to indicate the distance between the first position of the tray and the target object, and the second distance signal is used to indicate the distance between the second position of the tray and the target object. The first position and the second position are set at intervals.

[0097] Step S20, judging the first detection state and the second detection state (specifically step S21...

Embodiment 2

[0118] Such as Figure 6-7 As shown, this embodiment discloses a tray extension positioning system 10 , which includes: a first acquiring module 110 , a first judging module 210 , a first driving module 310 , a second driving module 320 and a third driving module 330 .

[0119] The first obtaining module 110 is used for obtaining the first detection state of the first sensor 31 and the second detection state of the second sensor 32 . The first detection state is used to indicate whether the first sensor 31 detects the first distance signal, and the second detection state is used to indicate whether the second sensor 32 detects the second distance signal. The first distance signal is used to indicate the distance between the first position of the tray 20 and the target object, and the second distance signal is used to indicate the distance between the second position of the tray 20 and the target object. The first position and the second position are set at intervals.

[0120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com