Lens reversing device and method

A film rewinding and lens technology, which is applied in the field of film rewinding devices, can solve problems such as inconvenient access to lenses, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

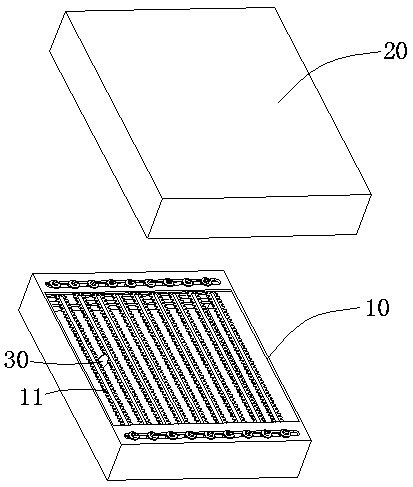

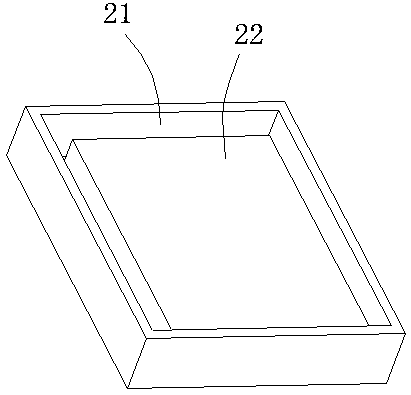

[0032] Please refer to figure 1 and figure 2 , which shows a film rewinding device 100 provided by an embodiment of the present invention, which includes a swing frame 10 and a lens tray 20, a number of lenses 30 are evenly placed on the swing frame 10, and the lens tray 20 is detachable The cover is buckled on the swing frame 10. When the lens tray 20 is covered with the swing frame 10, the relative position between the lens tray 20 and the swing frame 10 is fixed, and the lens tray 20 The layout limits that each lens 30 cannot break away from the swing frame 10 .

[0033] Specifically, in the above-mentioned embodiment, the swing frame 10 has several sawtooth bars 11, and the several sawtooth bars 11 are arranged at equal intervals along the width direction of the swing frame 10, and the lenses 30 are sandwiched between adjacent Between the two sawtooth bars 11 , every N lenses 30 among the plurality of lenses 30 are arranged in a row along the length direction of the swi...

Embodiment 2

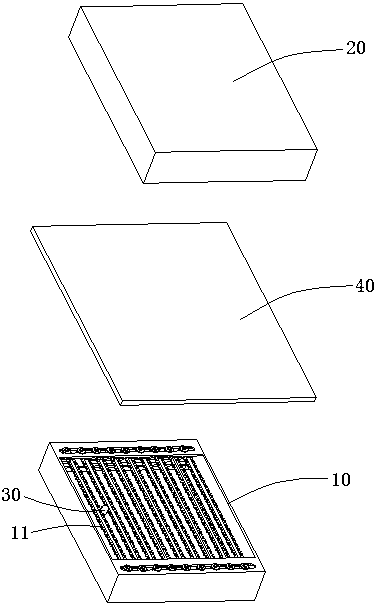

[0037] Please refer to image 3 , which shows another film rewinding device 100 provided by the embodiment of the present invention, which includes a swing frame 10 and a lens tray 20 . The difference between this embodiment and the first embodiment is that the film rewinding device 100 of this embodiment further includes an isolation layer 40 .

[0038] Specifically, the isolation layer 40 is placed between the lens tray 20 and the swing frame 10 , and both sides of the isolation layer 40 are respectively in contact with the lens tray 20 and each lens 30 . In this embodiment, the isolation layer 40 is a piece of white paper, but of course it can also be other types of articles. The effect of the isolation layer 40 is similar to that of the above sponge layer 22 , both are to prevent the lens 30 from directly contacting the lens disk 20 , and the isolation layer 40 and the sponge layer 22 form a double layer of protection. At the same time, since the isolation layer 40 is in...

Embodiment 3

[0041] Please refer to Figure 4 , which shows another film rewinding device 100 provided by the embodiment of the present invention, which includes a swing frame 10 and a lens tray 20 . The difference between this embodiment and the second embodiment is that the swing frame 10 and the lens tray 20 in this embodiment can be engaged with each other, so as to limit the position of the swing frame 10 and the lens tray 20 .

[0042] Specifically, a buckle 23 is provided on one side of the lens disc 20, and a buckle groove 12 is provided at a position corresponding to the buckle 23 on the swing frame 10. When the lens disc 20 is buckled and covered on the When the swing frame 10 is above, the buckle 23 and the buckle groove 12 are engaged with each other, thereby defining the relative position of the swing frame 10 and the lens tray 20 . In this way, during the overturning process of the pendulum frame 10 and the lens disc 20, the lens 30 will not fall out due to the instability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com