Fluidized bed semi-dry desulfurization system and method

A desulfurization system and fluidized bed technology, applied in the field of fluidized bed semi-dry desulfurization system, can solve the problems of poor dust removal performance of the pre-dust removal device, unfavorable dust removal efficiency of the pre-dust removal device, etc., to achieve enhanced dust removal effect and enhanced practicability , The effect of guaranteeing the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

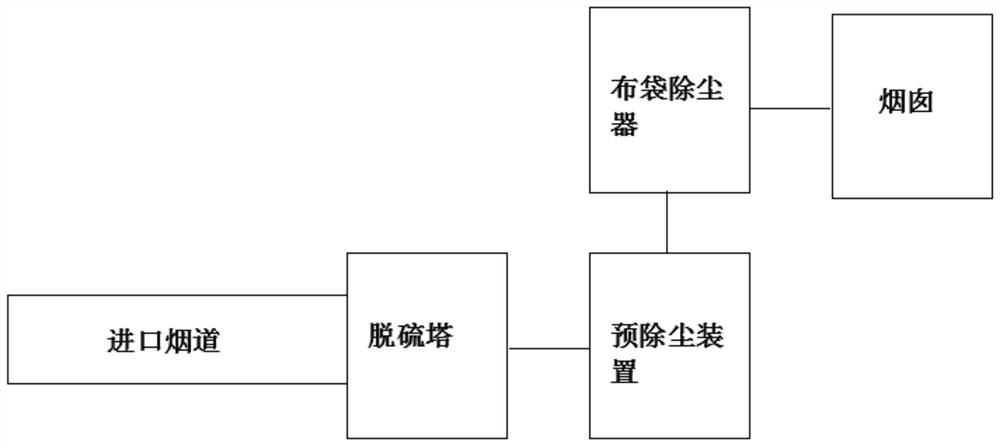

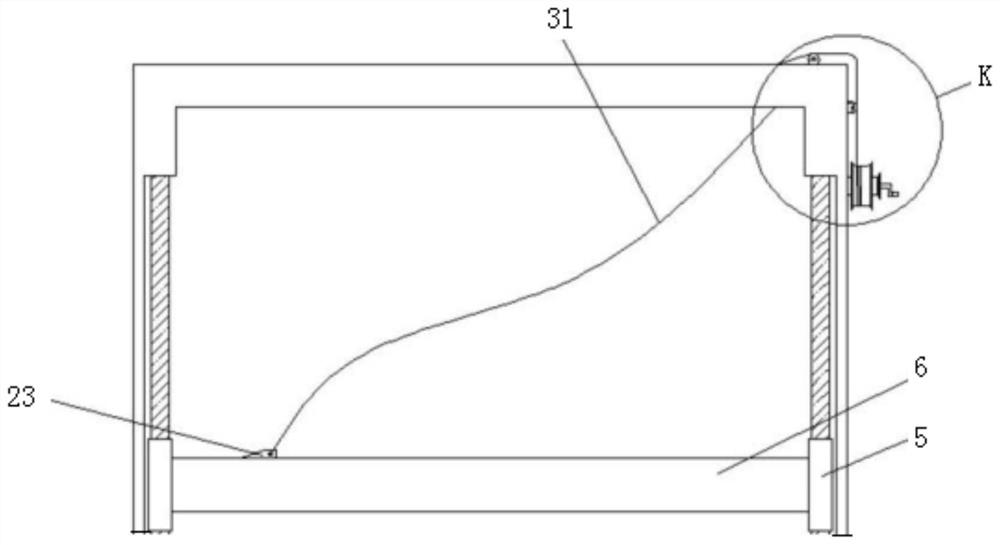

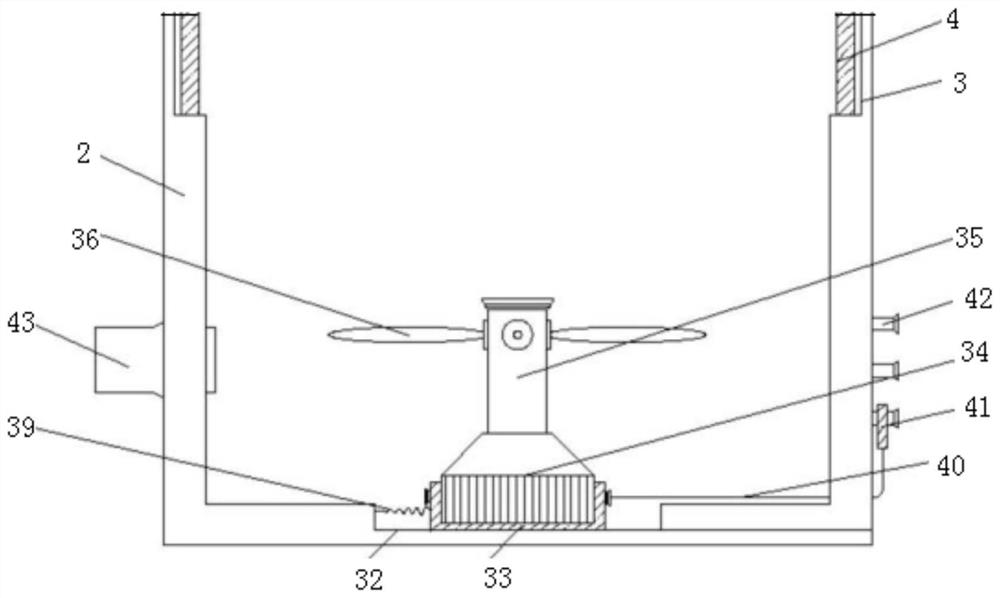

[0037] like Figure 1-Figure 6As shown, the fluidized bed semi-drying desulfurization system includes a pre-dusting device connected with a desulfurization tower and a bag filter; the pre-dusting device includes a hollow shell 2, and both sides of the inner surface of the hollow shell 2 are The guide rails 3 are provided, and the number of the guide rails 3 is a pair. The other pair of the guide rails 3 are distributed in a mirror image with the vertical center line of the hollow shell 2 acting as a mirror image line. The upper end and the lower end are fixedly connected to the guide column 4 by welding, the upper sleeve of the guide column 4 is provided with a circular column-shaped guide plate 5, and the other pair of the guide plates 5 are fixedly connected to the disc-shaped disc-shaped body. 6. An insertion port 22, a cylindrical opening 7 and a rectangular parallelepiped opening 8 are sequentially opened on the upper end of the disc-shaped body 6 from one side to the oth...

Embodiment 2

[0039] The fluidized bed semi-drying desulfurization system includes a pre-dust removal device connected to a desulfurization tower and a bag filter; the pre-dust removal device includes a hollow shell 2, and guide rails are provided on both sides of the inner surface of the hollow shell 2 3. The number of the guide rails 3 is a pair, and the other pair of the guide rails 3 are distributed in mirror images with the vertical center line of the hollow shell 2 acting as a mirror image line. The upper and lower ends of the inner surface of the guide rails 3 The guide column 4 is fixedly connected with the guide column 4 by welding, the upper sleeve of the guide column 4 is provided with a circular column-shaped guide plate 5, and the other pair of the guide plates 5 is fixedly connected with the disc-shaped disc-shaped body 6, so The upper end of the disc-shaped body 6 is sequentially opened with an insertion port 22 , a cylindrical opening 7 and a rectangular parallelepiped openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com