Efficient dust removal device for building construction protection

A technology for building construction and dust removal devices, which is applied in the direction of using liquid separation agents, cleaning methods and utensils, cleaning methods using tools, etc., which can solve the problem that the dust removal work cannot meet the ideal requirements, increase the dust removal burden of operators, and cannot handle dust, etc. problems, to achieve the effect of strengthening dust removal effect and practical value, increasing the convenience of dust cleaning, increasing efficiency and comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

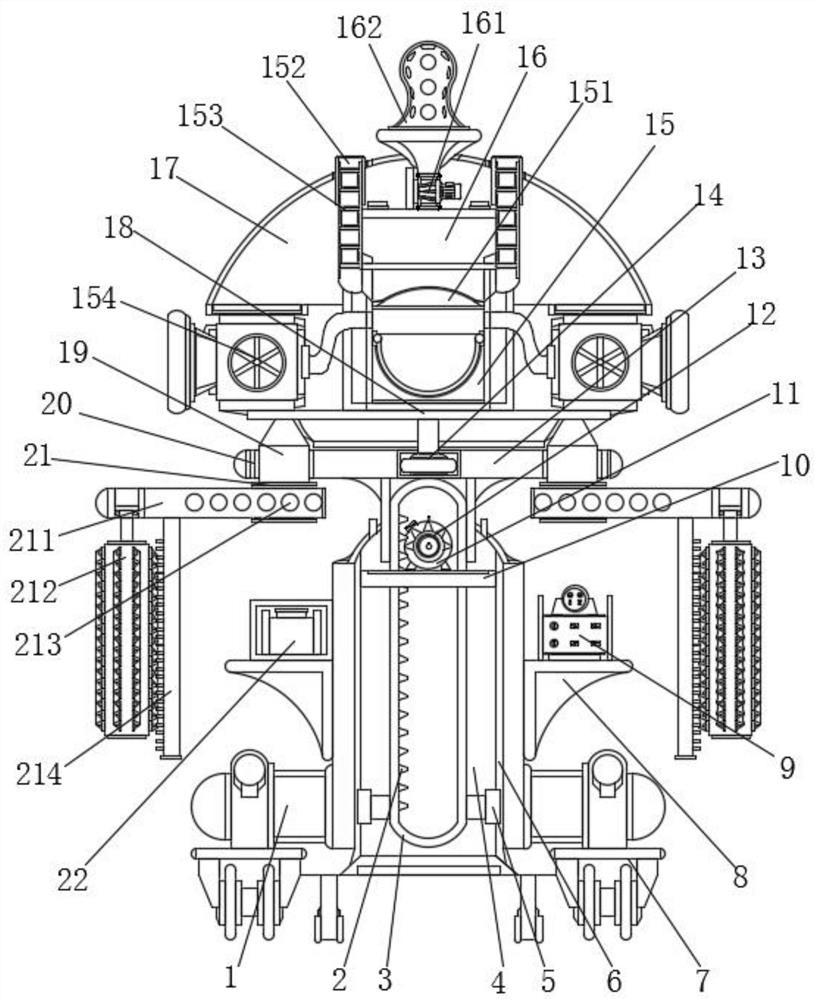

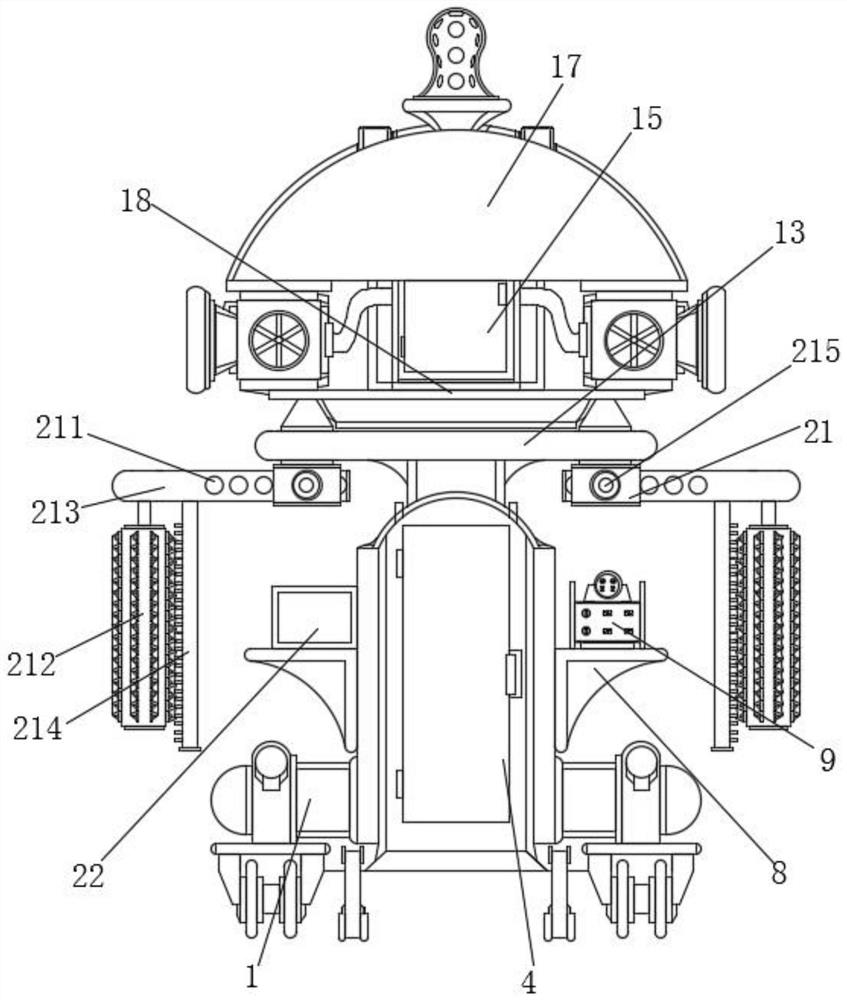

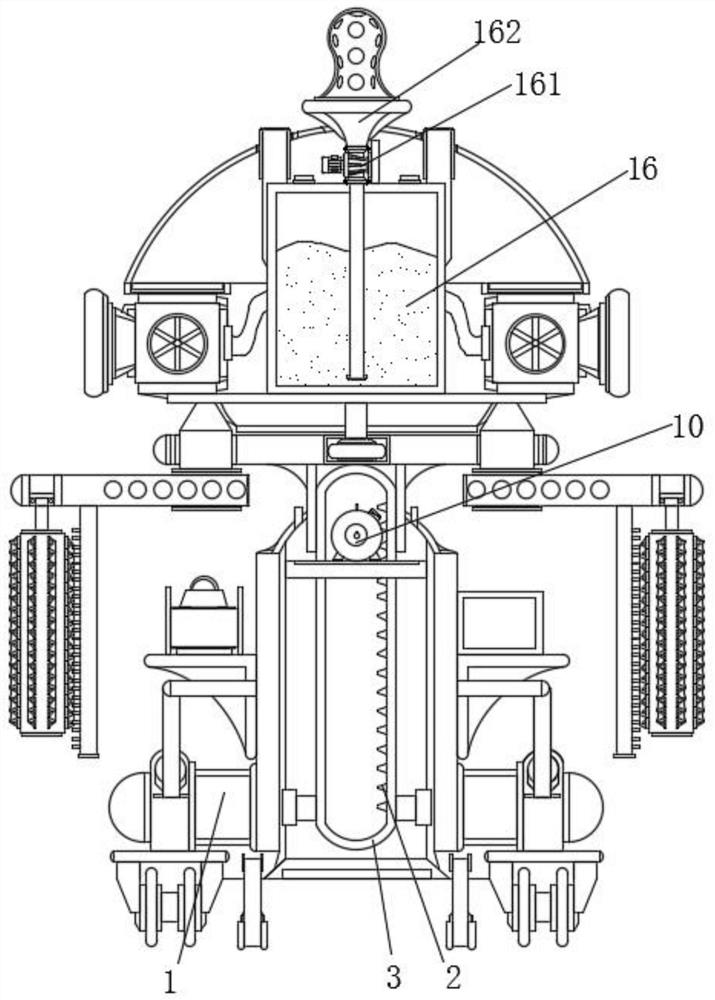

[0031] Example 1, such as Figure 1-3 As shown, under the rotation of the dust removal and purification assembly and the spraying and dust reduction assembly, the servo motor 11 can be started through the console 9, and the servo motor 11 is used to drive the incomplete gear 12 to cooperate with the rack 2, so that the installation frame 3 is in a short intermittent Lifting work, so that when the incomplete gear 12 is always meshed with the rack 2, it will rise as a whole under the guidance of the slider 5 and the chute 6 through the installation frame 3. The structure of the adjustment activity cooperates with the large-scale dust removal treatment work, which increases the comprehensiveness of the dust removal work of the device.

Embodiment 2

[0032] Example 2, such as Figure 1-3 As shown, when there is too much dust on the construction device or the wall surface, the distance between the cleaning rollers 212 can be adjusted by using the sleeve rod 211 under the interspersed fit of the sleeve 21, and fixed by the cooperation of the bolt 215 and the socket 213, That is, with the rotation of the guide block 19 in the annular guide groove 20, the cleaning roller 212 is driven to contact the device that needs to be brushed, and the rotation generated by the contact of the cleaning roller 212 is used to cooperate with the brush plate 214 to adhere the cleaning roller 212 The dust is brushed off and treated with dust removal and purification components or spraying dust reduction components to increase the functionality of the device.

[0033] Working principle: when the device is in use, first move it to the designated position, then use the console 9 to respectively start the drive motor 14, the suction fan 154 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com